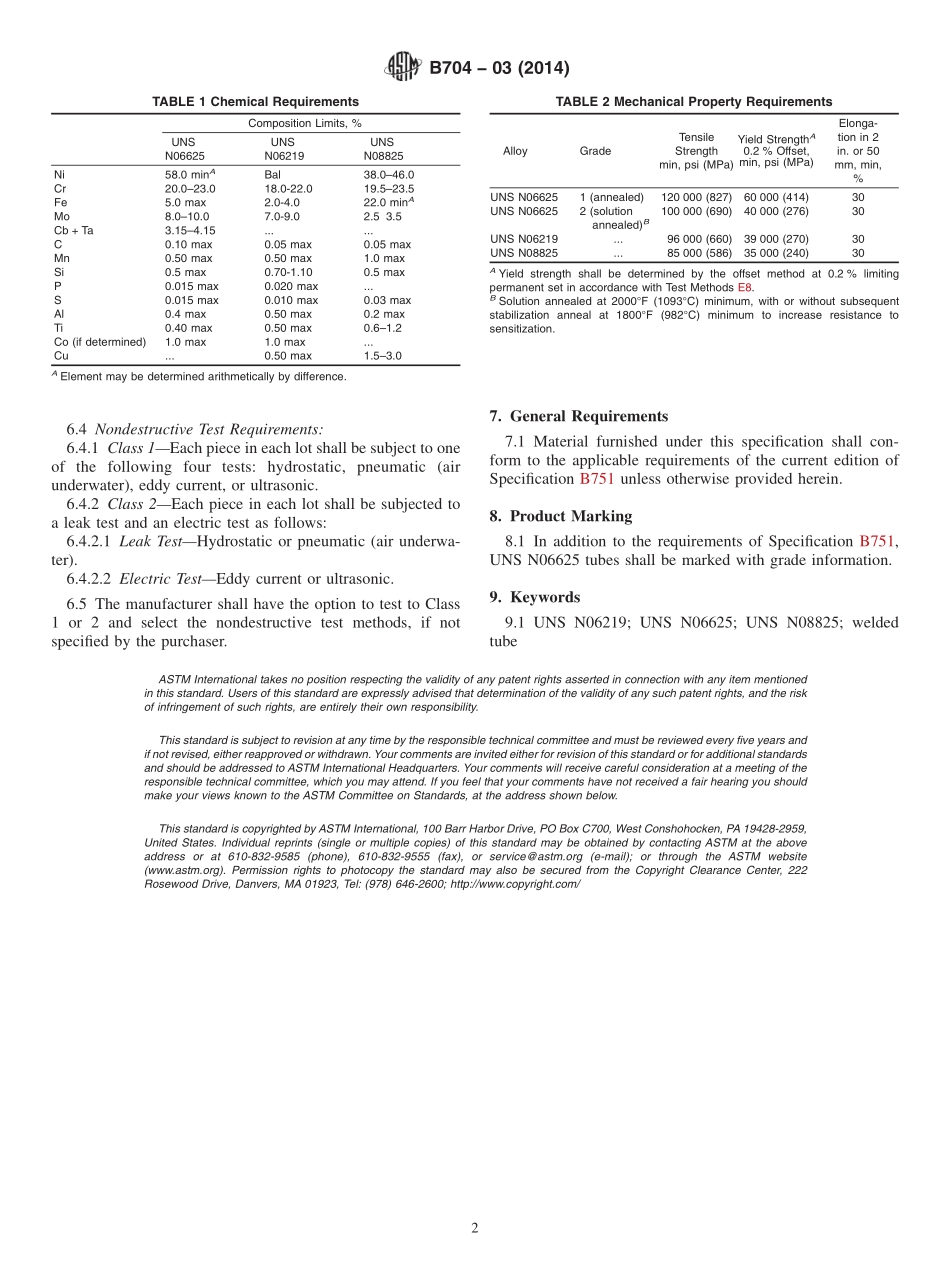

Designation:B704−03(Reapproved2014)StandardSpecificationforWeldedUNSN06625,UNSN06219andUNSN08825AlloyTubes1ThisstandardisissuedunderthefixeddesignationB704;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1ThisspecificationcoversweldedUNSN06625,UNSN06219andUNSN08825alloyboiler,heatexchanger,andcondensertubesforgeneralcorrosionresistingandloworhigh-temperatureservice.1.2Thisspecificationcoverstubes1⁄8to5in.(3.18to127mm),inclusive,inoutsidediameterand0.015to0.500in.(0.38to12.70mm),inclusive,inwallthickness.SpecificationB751liststhedimensionalrequirementsofthesesizes.Tubeshavingotherdimensionsmaybefurnishedprovidedsuchtubingcomplieswithallotherrequirementsofthisspecification.1.3Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.ItistheresponsibilityoftheuserofthisstandardtobecomefamiliarwithallhazardsincludingthoseidentifiedintheappropriateMaterialSafetyDataSheet(MSDS)forthisproduct/materialasprovidedbythemanufacturer,toestablishappropriatesafetyandhealthpractices,anddeterminetheapplicabilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2B751SpecificationforGeneralRequirementsforNickelandNickelAlloyWeldedTubeE8TestMethodsforTensionTestingofMetallicMaterials3.OrderingInformation3.1Ordersformaterialtothisspecificationshouldincludethefollowinginformation:3.1.1Quantity(feetornumberoflengths),3.1.2UNSnumber,3.1.3Size(outsizediameter,minimumoraveragewallthickness),3.1.4Length(randomorspecific),3.1.5Class,and3.1.6GradeifUNSN06625isspecified.IfneithergradeofN06625isspecified,grade1willbesupplied.3.1.7ASTMdesignation.3.1...