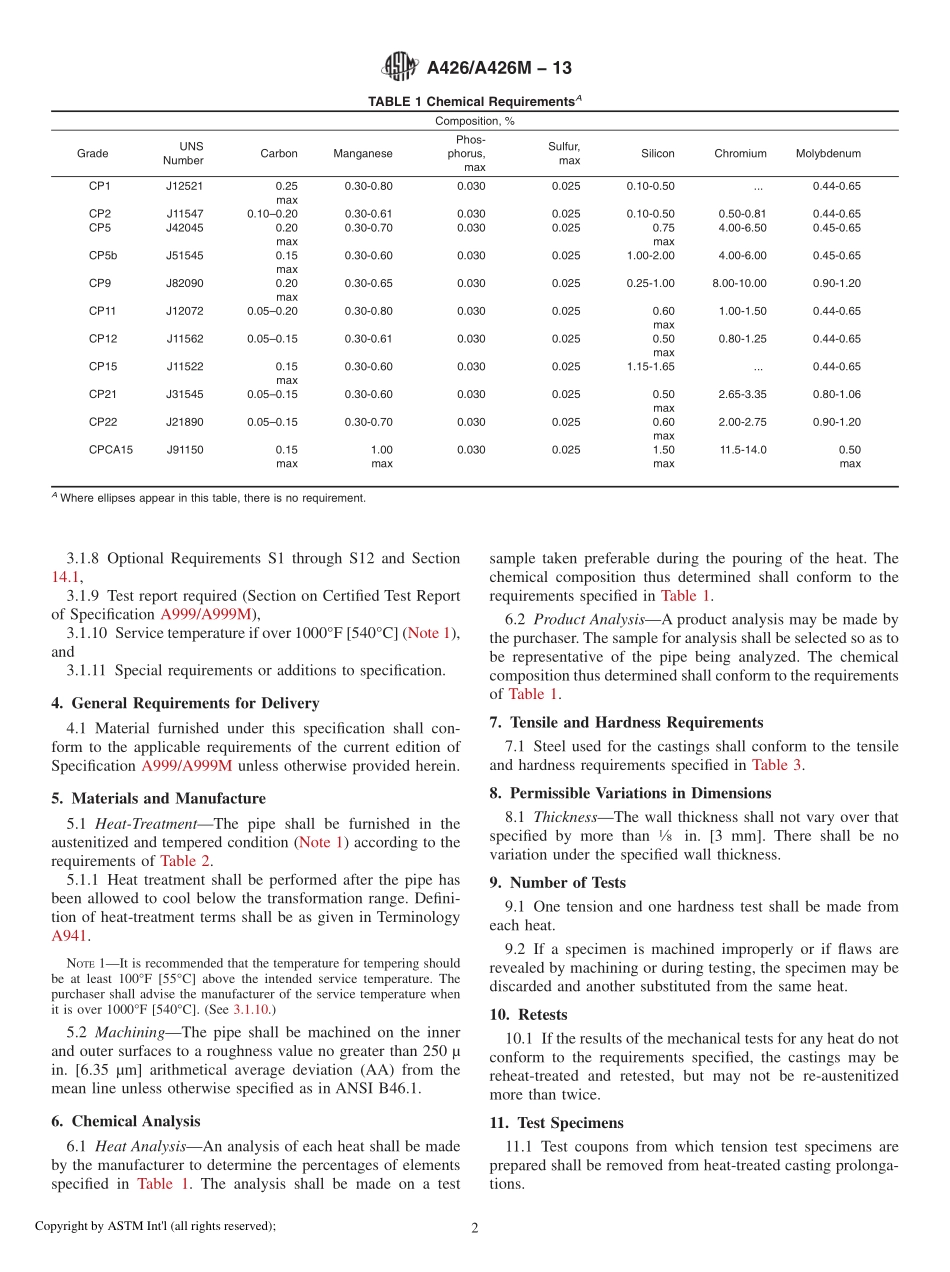

Designation:A426/A426M−13StandardSpecificationforCentrifugallyCastFerriticAlloySteelPipeforHigh-TemperatureService1ThisstandardisissuedunderthefixeddesignationA426/A426M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisspecification2coverscentrifugallycastalloysteelpipeintendedforuseinhigh-temperature,high-pressureser-vice.1.2Severalgradesofferriticsteelsarecovered.TheircompositionsaregiveninTable1.1.3SupplementaryRequirementsS1throughS12areprovided.Thesupplementaryrequirementsprovideforaddi-tionaltestsofanoptionalnatureandwhendesiredshallbesostatedintheorder(Section4).1.4Thevaluesstatedineitherinch-poundunitsorSIunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.1.4.1Withinthetext,theSIunitsareshowninbrackets.1.5Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:3A370TestMethodsandDefinitionsforMechanicalTestingofSteelProductsA609/A609MPracticeforCastings,Carbon,Low-Alloy,andMartensiticStainlessSteel,UltrasonicExaminationThereofA941TerminologyRelatingtoSteel,StainlessSteel,RelatedAlloys,andFerroalloysA999/A999MSpecificationforGeneralRequirementsforAlloyandStainlessSteelPipeE94GuideforRadiographicExaminationE165PracticeforLiquidPenetrantExaminationforGeneralIndustryE186ReferenceRadiographsforHeavy-Walled(2to41⁄2-in.(50.8to114-mm))SteelCastingsE208TestMethodforConductingDrop-WeightTesttoDetermineNil-DuctilityTransitionTemperatureofFer-riticSteelsE280Refe...