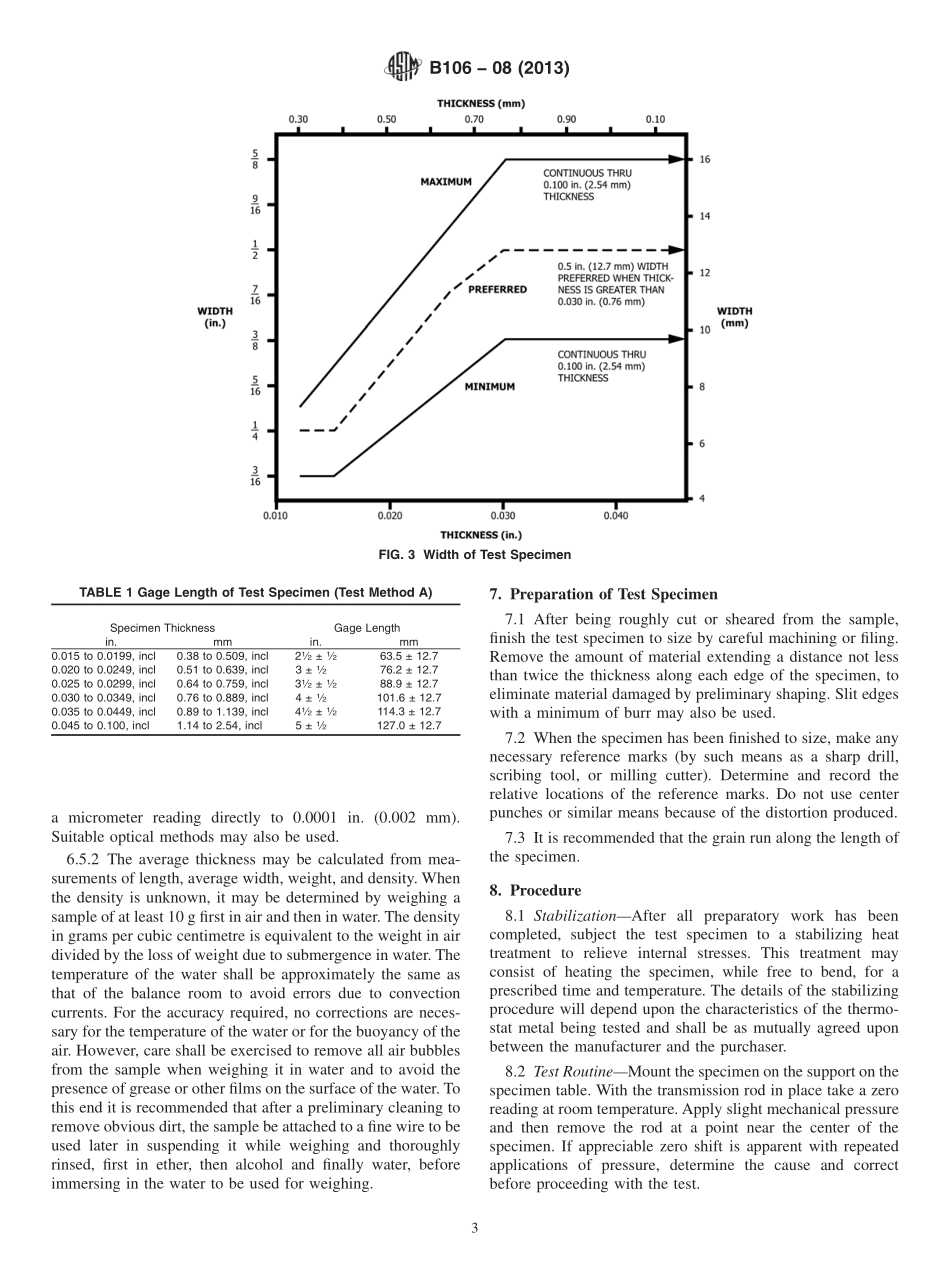

Designation:B106−08(Reapproved2013)StandardTestMethodsforFlexivityofThermostatMetals1ThisstandardisissuedunderthefixeddesignationB106;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thesetestmethodscoverthedeterminationofflexivity(ameasureofthermaldeflectionrateordeflectiontemperaturecharacteristics)ofthermostatmetals.1.1.1TestMethodA—Testedintheformofflatstrip0.015in.(0.38mm)oroverinthickness.1.1.2TestMethodB—Testedintheformofspiralcoilslessthan0.012in.inthickness.1.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.ItistheresponsibilityoftheuserofthisstandardtobecomefamiliarwithallhazardsincludingthoseidentifiedintheappropriateMaterialSafetyDataSheet(MSDS)forthisproduct/materialasprovidedbythemanufacturer,toestablishappropriatesafetyandhealthpractices,anddeterminetheapplicabilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2B389TestMethodforThermalDeflectionRateofSpiralandHelicalCoilsofThermostatMetal3.Terminology3.1Definitions:3.1.1thermostatmetal,n—acompositematerialintheformofsheetorstripcomprisingtwoormoremetalliclayersofdifferingcoefficientsofthermalexpansion,suchthattheradiusofcurvatureofthecompositechangeswithtemperaturechange.3.1.2flexivity(F),n—thechangeofcurvatureofthelongi-tudinalcenterlineofthespecimenperunittemperaturechangeforunitthickness,givenbythefollowingequation:F5t~1/R2!2~1/R1!T22T1(1)Todeterminetheflexivitybetweenanytwotemperatures,T1andT2,itisnecessarytomeasurethecurvature1/R1and1/R2attemperatureT1andT2,respectively.Tofindthecur-vatureateithertemperature(Fig.1andFig.2),measureth...