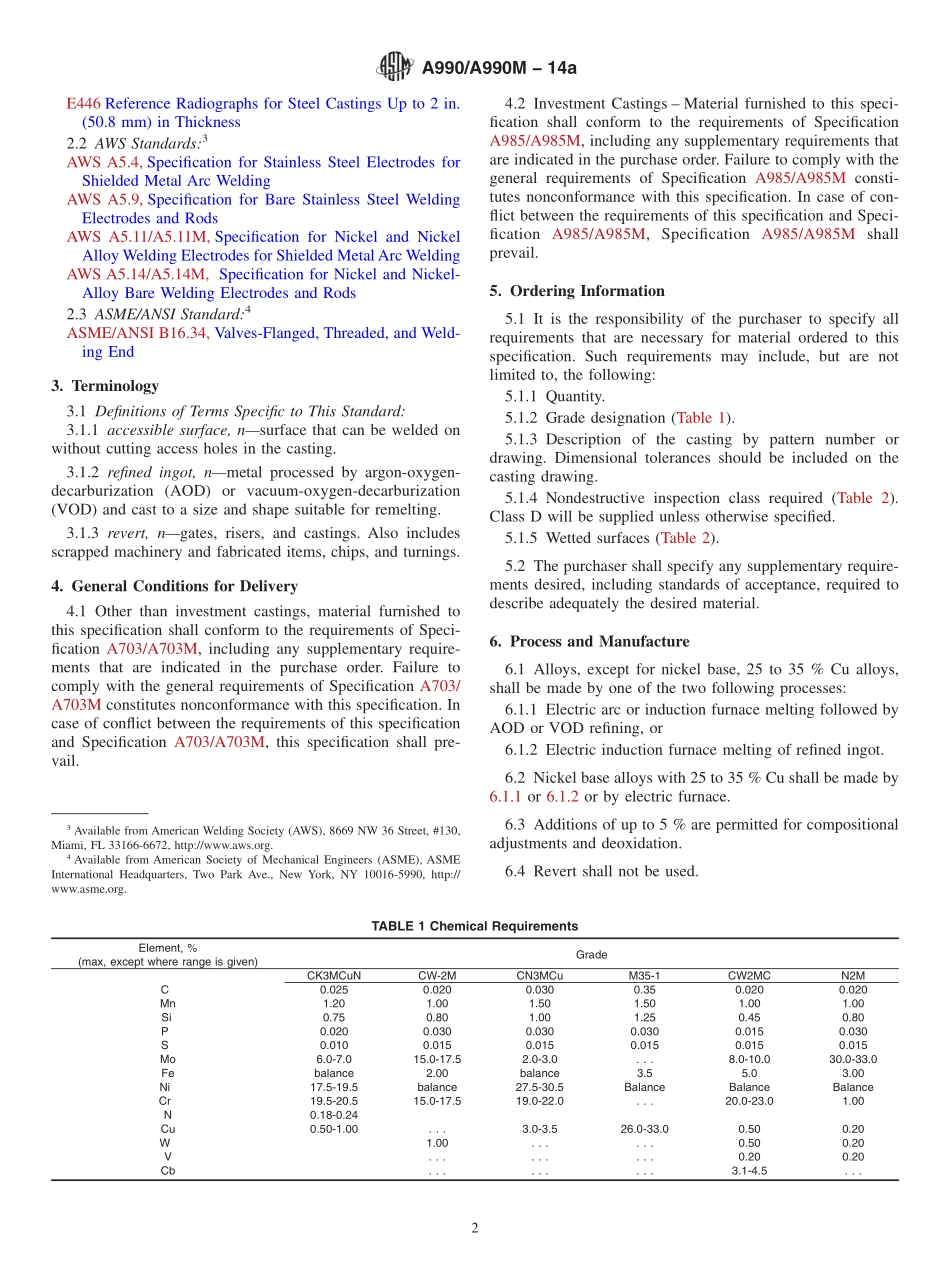

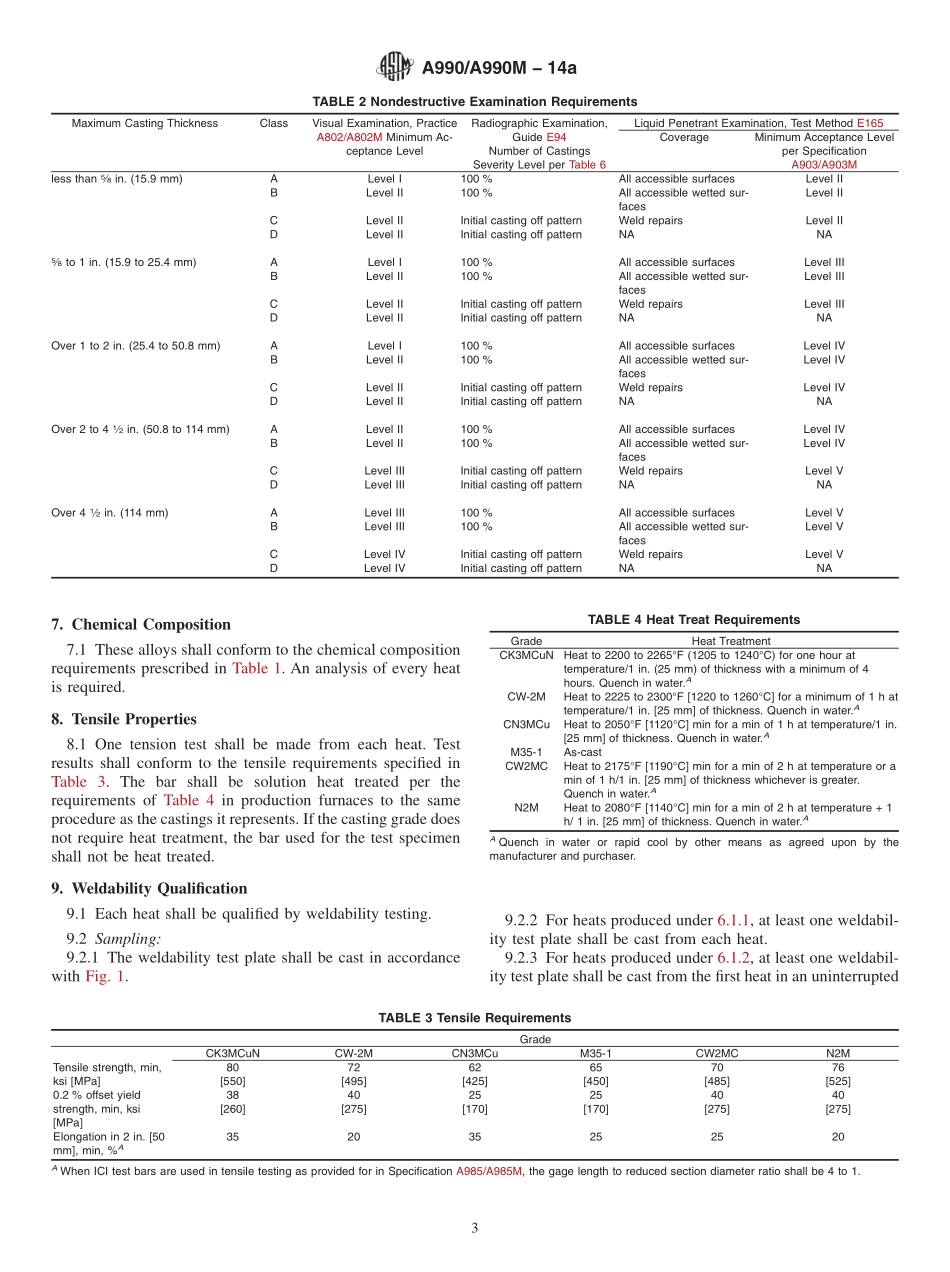

Designation:A990/A990M−14aStandardSpecificationforCastings,Iron-Nickel-ChromiumandNickelAlloys,SpeciallyControlledforPressureRetainingPartsforCorrosiveService1ThisstandardisissuedunderthefixeddesignationA990/A990M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisspecificationcoversiron-nickel-chromiumandnickelalloycastingsspeciallyprocessedwithrestrictedmeltpractices,weldabilitytesting,andnondestructiveexamination(NDE)requirements.1.2Anumberofgradesofiron-nickel-chromiumandnickelalloycastingsareincludedinthisspecification.Sincethesegradespossessvaryingdegreesofsuitabilityforserviceincorrosiveenvironments,itistheresponsibilityofthepurchasertodeterminewhichgradeshallbefurnished.Selectionwilldependondesignandserviceconditions,mechanicalproperties,andcorrosion-resistantcharacteristics.1.3ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.1.3.1Thisspecificationisexpressedinbothinch-poundunitsandinSIunits;however,unlessthepurchaseorderorcontractspecifiestheapplicableMspecificationdesignation(SIunits),theinch-poundunitsshallapply.Withinthetext,theSIunitsareshowninbracketsorparentheses.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2A351/A351MSpecificationforCastings,Austenitic,forPressure-ContainingPartsA488/A488MPracticeforSteelCastings,Welding,Qualifi-cationsofProceduresandPersonnelA494/A494MSpecificationforCas...