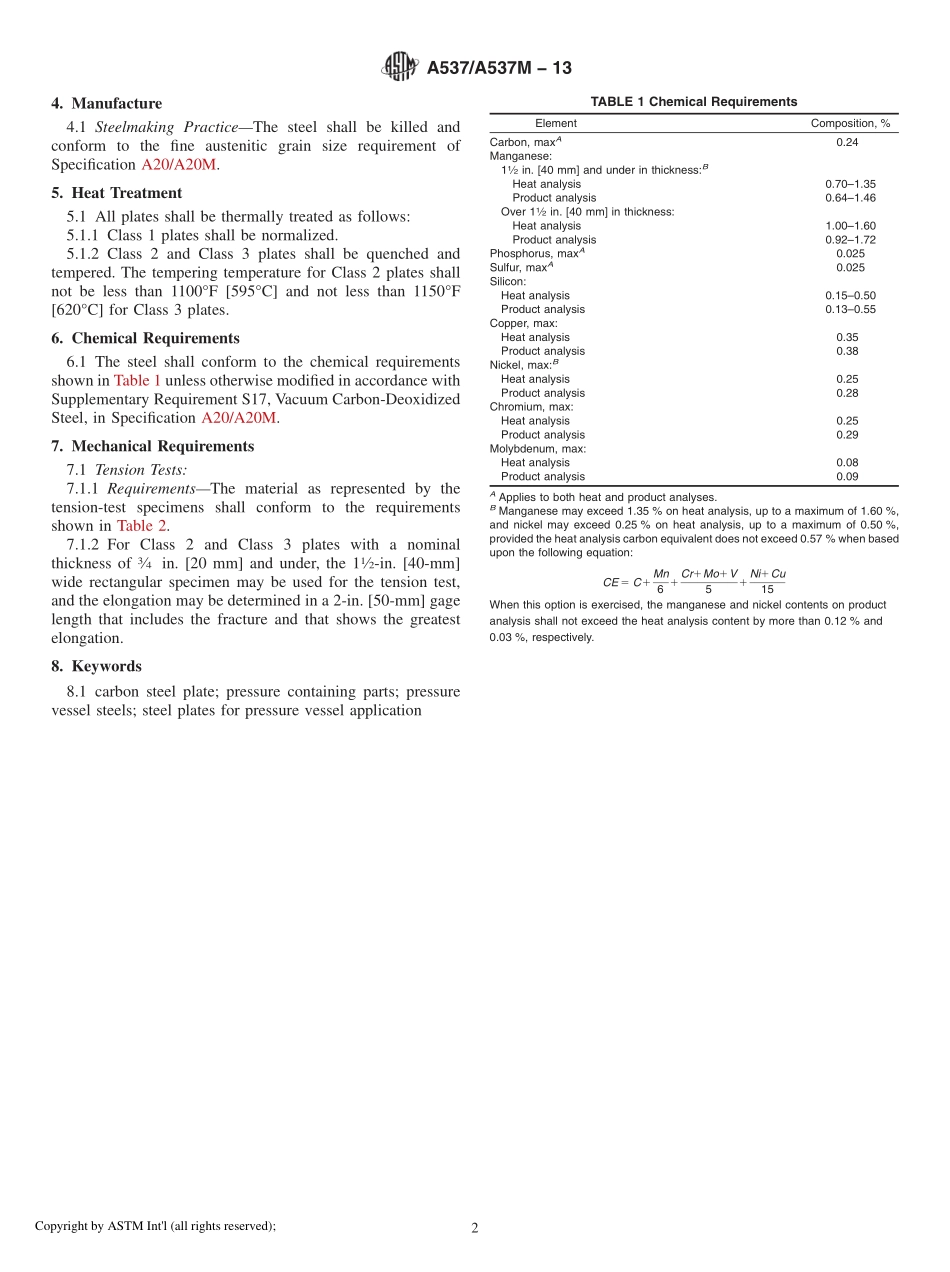

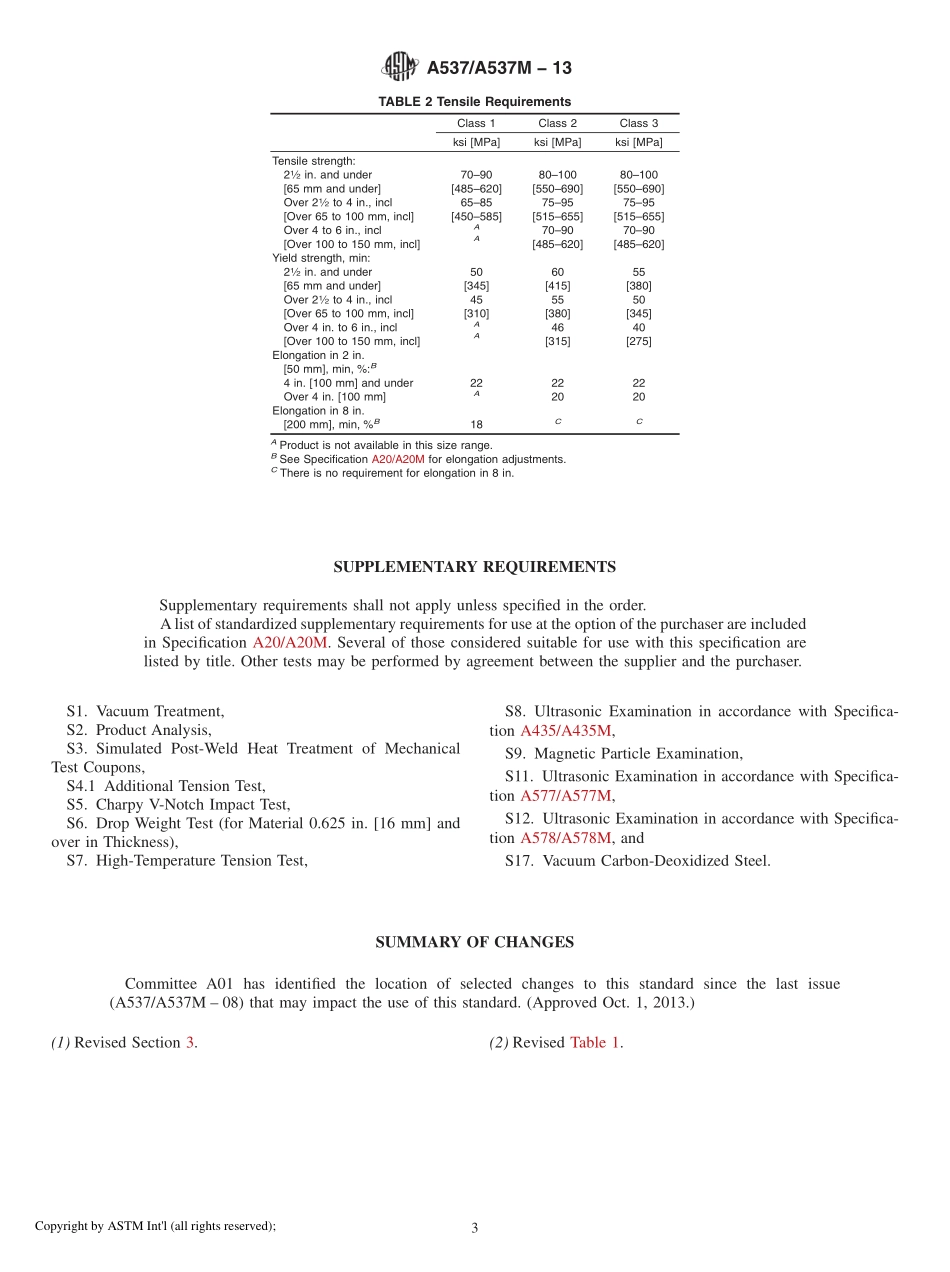

Designation:A537/A537M−13StandardSpecificationforPressureVesselPlates,Heat-Treated,Carbon-Manganese-SiliconSteel1ThisstandardisissuedunderthefixeddesignationA537/A537M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope*1.1Thisspecification2coversheat-treatedcarbon-manganese-siliconsteelplatesintendedforfusionweldedpressurevesselsandstructures.1.2Platesfurnishedunderthisspecificationareavailableinthefollowingthreeclasses:YieldTensileStrength,Strength,HeatThickness,min,ksimin,ksiClassTreatment[MPa][MPa]1Normalized21⁄2in.andunder[65mmandunder]50[345]70[485]Over21⁄2to4in.[Over65to100mm]45[310]65[450]2Quenchedandtempered21⁄2in.andunder[65mmandunder]60[415]80[550]Over21⁄2to4in.[Over65to100mm]55[380]75[515]Over4to6in.[Over100to150mm]46[315]70[485]3Quenchedandtempered21⁄2in.andunder[65mmandunder]55[380]80[550]Over21⁄2to4in.[Over65to100mm]50[345]75[515]Over4to6in.[Over100to150mm]40[275]70[485]1.3Themaximumthicknessofplatesfurnishedunderthisspecificationis4in.[100mm]forClass1and6in.[150mm]forClass2andClass3.1.4Thevaluesstatedineitherinch-poundunitsorSIunitsaretoberegardedseparatelyasstandard.Withinthetext,theSIunitsareshowninbrackets.Thevaluesstatedineachsystemarenotexactequivalents;therefore,eachsystemistobeusedindependentlyoftheotherwithoutcombiningvaluesinanyway.2.ReferencedDocuments2.1ASTMStandards:3A20/A20MSpecificationforGeneralRequirementsforSteelPlatesforPressureVesselsA435/A435MSpecificationforStraight-BeamUltrasonicExaminationofSteelPlatesA577/A577MSpecificationforUltrasonicAngle-BeamEx-aminationofSteelPlatesA578/A578MSpecificationforStraight-BeamUltrasonicExaminationofRolledSteelPlatesforSpecialApplica-tions3.GeneralRequirementsandOrderingInformation3.1Platesfurnishedsuppliedtot...