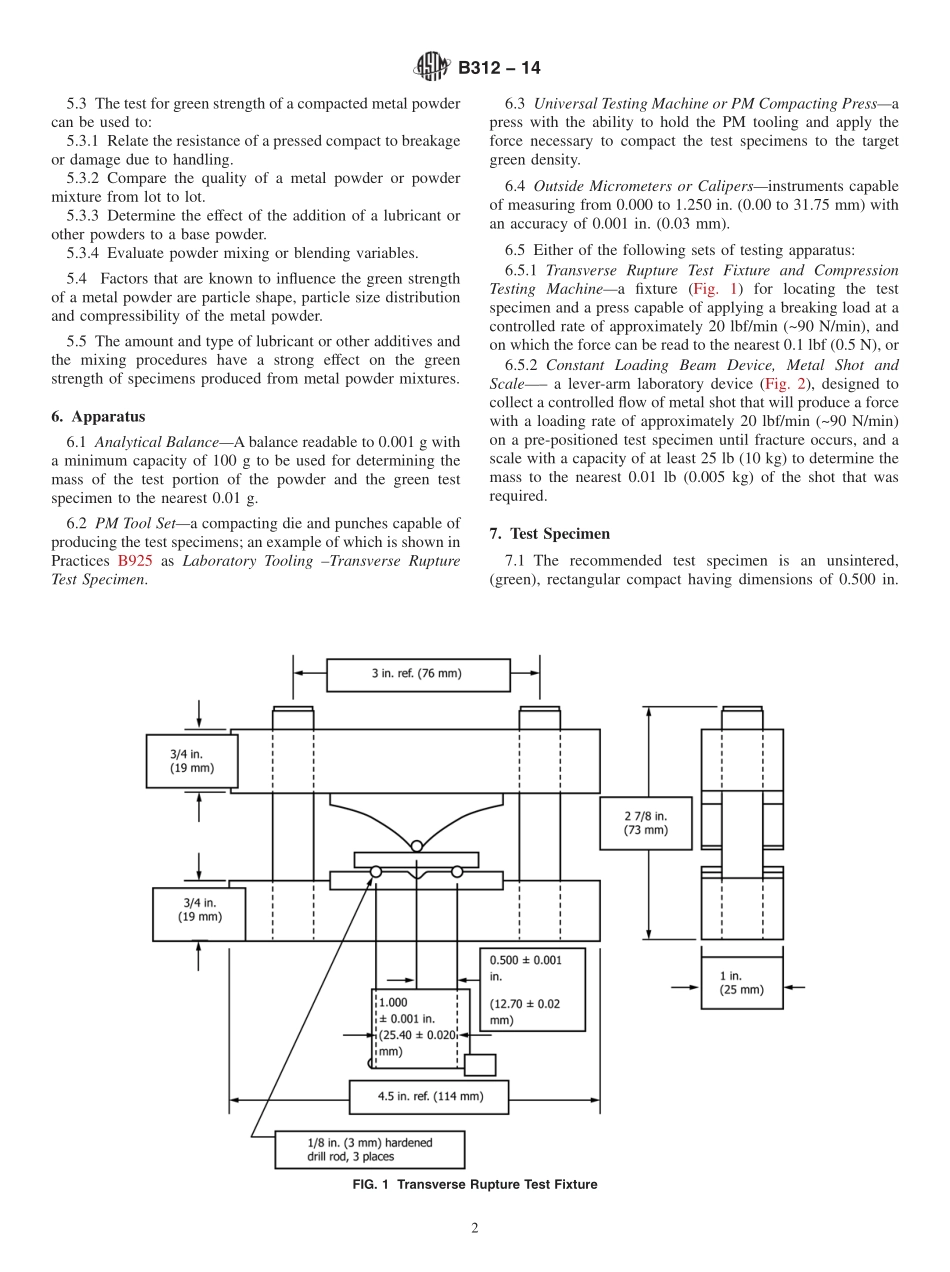

Designation:B312−14StandardTestMethodforGreenStrengthofSpecimensCompactedfromMetalPowders1ThisstandardisissuedunderthefixeddesignationB312;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisstandardcoversatestmethodthatmaybeusedtomeasurethetransverserupturestrengthofacompactedbutunsintered(green)testspecimenproducedfromlubricatedorunlubricatedmetalpowdersorpowdermixtures.1.2Greenstrengthismeasuredbyaquantitativelaboratoryprocedureinwhichthefracturestrengthiscalculatedfromtheforcerequiredtobreakanunsinteredtestspecimensupportedasasimplebeamwhilesubjectedtoauniformlyincreasingthree-pointtransverseloadundercontrolledconditions.1.3ThistestmethodisacompanionstandardtoTestMethodB528thatcoversthemeasurementofthetransverserupturestrengthofsinteredPMtestspecimens.1.4Withtheexceptionofthevaluesfordensityandthemassusedtodeterminedensity,forwhichtheuseofthegrampercubiccentimeter(g/cm3)andgram(g)unitsisthelong-standingindustrypractice,thevaluesininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.5Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2B215PracticesforSamplingMetalPowdersB243TerminologyofPowderMetallurgyB528TestMethodforTransverseRuptureStrengthofPow-derMetallurgy(PM)SpecimensB925PracticesforProductionandPreparationofPowderMetallurgy(PM)TestSpecimensB962TestMethodsforDensityofCompactedorSinteredPowderMetallurgy(PM)ProductsUsingArchimedes’PrincipleE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrec...