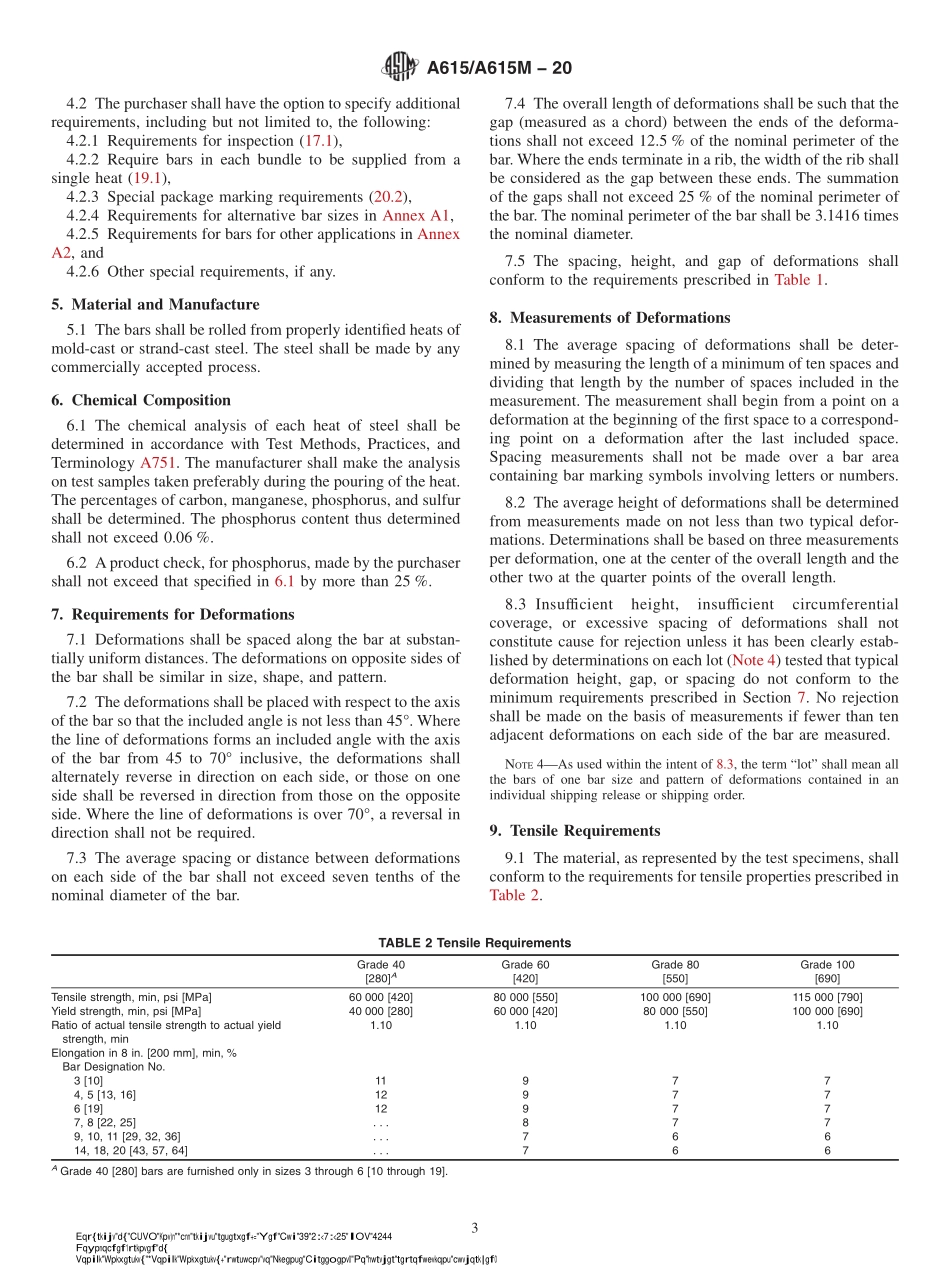

Designation:A615/A615M−20AmericanAssociationStateHighwayandTransportationOfficialsStandardAASHTONo.:M31StandardSpecificationforDeformedandPlainCarbon-SteelBarsforConcreteReinforcement1ThisstandardisissuedunderthefixeddesignationA615/A615M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope*1.1Thisspecificationcoversdeformedandplaincarbon-steelbarsincutlengthsandcoilsforconcretereinforcement.AnnexA2ofthisspecificationcoversdeformedbarsforuseforotherapplications.Steelbarscontainingalloyadditions,suchaswiththeAssociationforIronandSteelTechnologyandtheSocietyofAutomotiveEngineersseriesofalloysteels,arepermittediftheresultingproductmeetsalltheotherrequire-mentsofthisspecification.ThestandardsizesanddimensionsofdeformedbarsandtheirnumberdesignationsaregiveninTable1.1.2UnlessspecifiedforuseforotherapplicationsinAnnexA2,barsareoffourminimumyieldstrengthlevels:namely,40000psi[280MPa],60000psi[420MPa],80000psi[550MPa],and100000psi[690MPa],designatedasGrade40[280],Grade60[420],Grade80[550],andGrade100[690],respectively.NOTE1—Grade100[690]reinforcingbarswereintroducedinthisspecificationin2015.Incontrasttothelowergrades,whichhaveratiosofspecifiedtensilestrengthtospecifiedyieldstrengththatrangefrom1.25to1.50,Grade100[690]reinforcingbarshavearatioofspecifiedtensilestrengthtospecifiedyieldstrengthof1.15.Usersofthisspecificationshouldbeawarethattherewill,therefore,bealowermarginofsafetyandreducedwarningoffailurefollowingyieldingwhenGrade100[690]barsareusedinstructuralmemberswherestrengthisgovernedbythetensilestrengthofthereinforcement,primarilyinbeamsandslabs.Asaresultofthelowerspecifiedtensilestrengthtospecifiedyieldstrengthratioof1.15forGrade100[690],usersofthisspecificationshouldbeawarethatACI31...