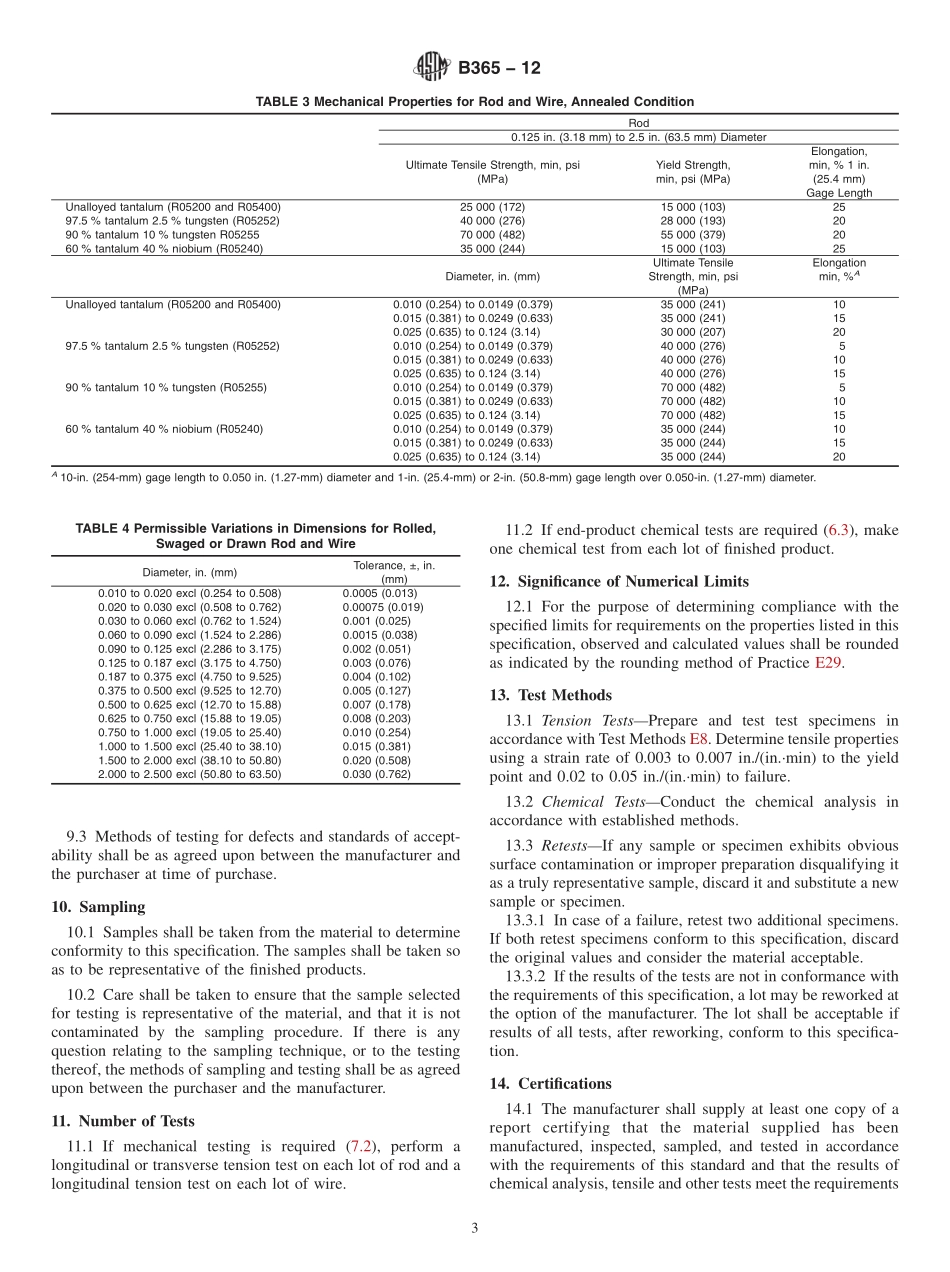

Designation:B365−12StandardSpecificationforTantalumandTantalumAlloyRodandWire1ThisstandardisissuedunderthefixeddesignationB365;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoversunalloyedandalloyedtanta-lumrodandwire.1.2Thematerialscoveredbythisspecificationare:1.2.1R05200,unalloyedtantalum,electron-beamfurnaceorvacuum-arcmelt,orboth,1.2.2R05400,unalloyedtantalum,powder-metallurgyconsolidation,1.2.3R05255,tantalumalloy,90%tantalum,10%tungsten,electron-beamfurnaceorvacuum-arcmelt,orboth,1.2.4R05252,tantalumalloy,97.5%tantalum,2.5%tungsten,electron-beamfurnaceorvacuum-arcmelt,orboth,and1.2.5R05240tantalumalloy,60%tantalum,40%niobium,electron-beamfurnaceorvacuum-arcmelt,orboth.1.3Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.4Thefollowingprecautionarycaveatpertainsonlytothetestmethodsportion,Section13,ofthisspecification:Thisstandarddoesnotpurporttoaddressallofthesafetyproblems,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimita-tionspriortouse.2.ReferencedDocuments2.1ASTMStandards:2E8TestMethodsforTensionTestingofMetallicMaterialsE29PracticeforUsingSignificantDigitsinTestDatatoDetermineConformancewithSpecifications3.Terminology3.1DefinitionsofTermsSpecifictoThisStandard:3.1.1lot,n—allmaterialproducedfromthesameingotorasinglepowderblendatonetime,withthesamecrosssectionandwiththesamenominalmetallurgicalparameters.3.1.2rod,n—material0.125to2.5in.(3.18to63.50mm)indiameterinround,hexagonal,oroctagonalcrosssectionsuppliedinstraightlengths.3.1.3wire,n—material0.010to0.124in.(0.254to3.15mm)...