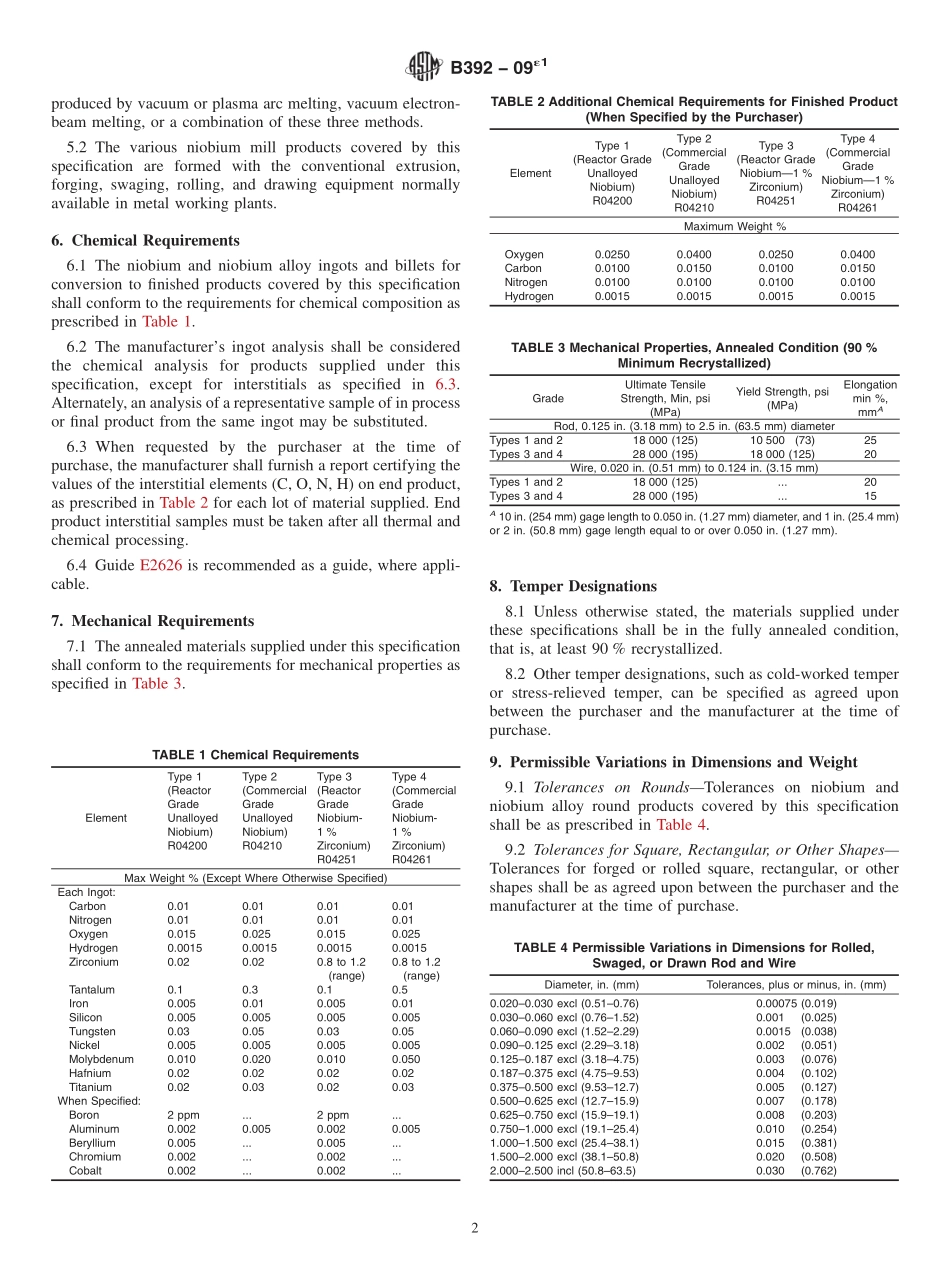

Designation:B392−09´1StandardSpecificationforNiobiumandNiobiumAlloyBar,Rod,andWire1ThisstandardisissuedunderthefixeddesignationB392;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.´1NOTE—EditorialcorrectionsweremadethroughoutinJanuary2010.1.Scope1.1Thisspecificationcoversfourgradesofwroughtnio-biumandniobiumalloybar,rod,andwireasfollows:1.1.1R04200-Type1—Reactorgradeunalloyedniobium,1.1.2R04210-Type2—Commercialgradeunalloyedniobium,1.1.3R04251-Type3—Reactorgradeniobiumalloycontain-ing1%zirconium,and1.1.4R04261-Type4—Commercialgradeniobiumalloycontaining1%zirconium.1.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.3Thefollowingprecautionarycaveatpertainsonlytothetestmethodsportionofthisspecification.Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2B391SpecificationforNiobiumandNiobiumAlloyIngotsE8TestMethodsforTensionTestingofMetallicMaterialsE29PracticeforUsingSignificantDigitsinTestDatatoDetermineConformancewithSpecificationsE2626GuideforSpectrometricAnalysisofReactiveandRefractoryMetals3.Terminology3.1DefinitionsofTermsSpecifictoThisStandard:3.1.1lot,n—alotshallconsistofallmaterialproducedfromthesameingotatonetime,withthesamecrosssection,processedwiththesamenominalmetallurgicalparametersandheattreatedatthesameconditions.3.1.2bar,n—materiallessthan6in.(152.4mm)inwidthand0.187in.(4.75mm)orgreaterinthickness,witharectangularcrosssection,suppliedinstraightlengths.3.1.3rod,n—material0.125to2.50...