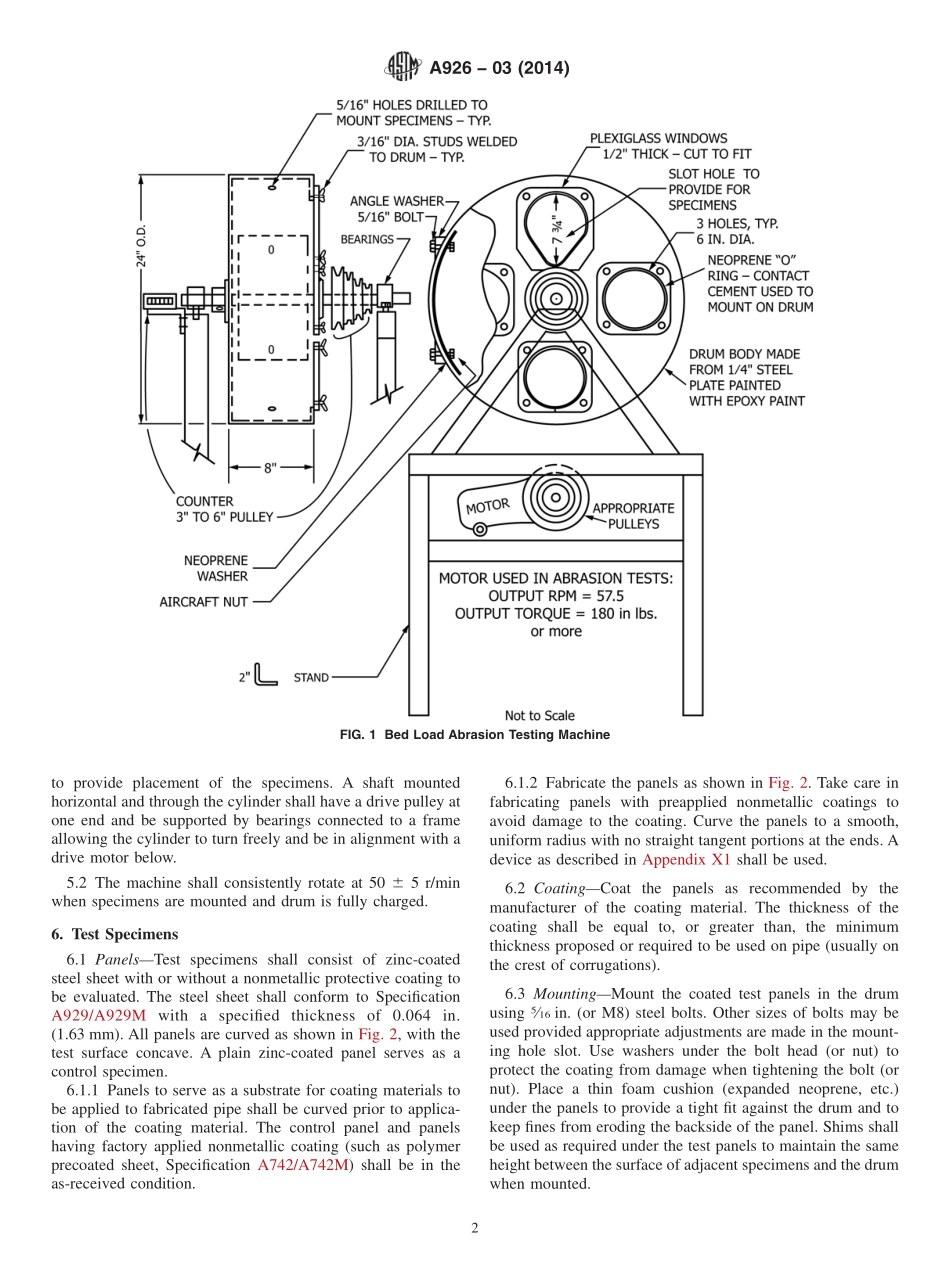

Designation:A926−03(Reapproved2014)StandardTestMethodforComparingtheAbrasionResistanceofCoatingMaterialsforCorrugatedMetalPipe1ThisstandardisissuedunderthefixeddesignationA926;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversaprocedureforcomparingmaterialsusedforcoating,pavingandliningcorrugatedmetalpipebyuseofabedloadabrasiontestingmachine.Theprocedureattemptstosimulatetheeffectofstone,gravelandsandcarriedbyastreamthroughcorrugatedmetalpipe.1.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard.TheSIunitsgiveninparenthesesareforinforma-tiononly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2A742/A742MSpecificationforSteelSheet,MetallicCoatedandPolymerPrecoatedforCorrugatedSteelPipeA849SpecificationforPost-AppliedCoatings,Pavings,andLiningsforCorrugatedSteelSewerandDrainagePipeA929/A929MSpecificationforSteelSheet,Metallic-CoatedbytheHot-DipProcessforCorrugatedSteelPipeC131TestMethodforResistancetoDegradationofSmall-SizeCoarseAggregatebyAbrasionandImpactintheLosAngelesMachineC136TestMethodforSieveAnalysisofFineandCoarseAggregates3.SummaryofTestMethod3.1Curvedsteelpanels,coatedwiththemattertobeevaluated,aremountedontheinsidesurfaceofacylindricaldrum.Achargeoffineaggregatecoarseaggregatesandwaterareaddedandthedrumissealed.Thenthedrumisrotatedtocauseanabrasiveflowoverthematerialsbeingtested.Aftertheprescribednumberofrevolutions,thepanelsareremovedfromthedrum,inspectedandweighedforloss;orAlternative2countinggridmethodisused.4.SignificanceandUse4.1Thistestmethodprovidesameansofdetermininganabrasionr...