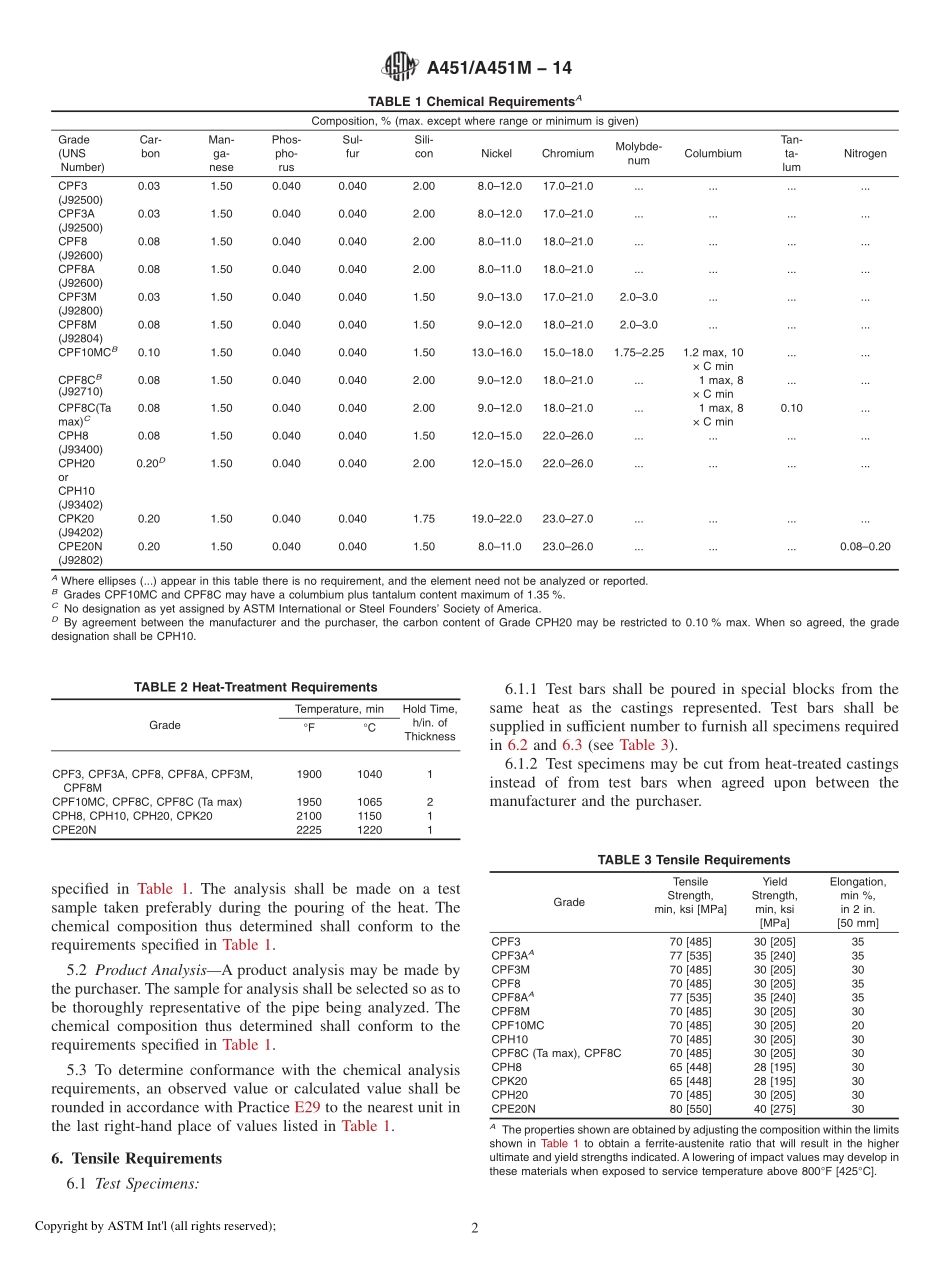

Designation:A451/A451M−14StandardSpecificationforCentrifugallyCastAusteniticSteelPipeforHigh-TemperatureService1ThisstandardisissuedunderthefixeddesignationA451/A451M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisspecification2coversausteniticalloysteelpipeforuseinhigh-temperature,corrosive,ornuclearpressureservice.1.2SeveralgradesofausteniticstainlesssteelarecoveredasindicatedinTable1.1.3Optionalsupplementaryrequirementsareprovidedwhenadditionaltestingmayberequired.1.4ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.NOTE1—Thisspecificationisnotintendedtocovercentrifugalpipemadefromalloyscontainingmorethan0.20%carbon,suchasarecoveredbySpecificationA297/A297M.1.4.1Withinthetext,theSIunitsareshowninbrackets.2.ReferencedDocuments2.1ASTMStandards:3A297/A297MSpecificationforSteelCastings,Iron-ChromiumandIron-Chromium-Nickel,HeatResistant,forGeneralApplicationA999/A999MSpecificationforGeneralRequirementsforAlloyandStainlessSteelPipeE29PracticeforUsingSignificantDigitsinTestDatatoDetermineConformancewithSpecificationsE94GuideforRadiographicExaminationE165PracticeforLiquidPenetrantExaminationforGeneralIndustryE186ReferenceRadiographsforHeavy-Walled(2to41⁄2-in.(50.8to114-mm))SteelCastingsE280ReferenceRadiographsforHeavy-Walled(41⁄2to12-in.(114to305-mm))SteelCastingsE446ReferenceRadiographsforSteelCastingsUpto2in.(50.8mm)inThickness2.2ANSIStandard:B46.1SurfaceTexture43.OrderingInformation3.1Ordersformaterialtothisspecificationshallincludethefollowing,asrequired,todescribethedesiredmaterialad-equately:3.1.1Quantity(feet,meters,ornumberof...