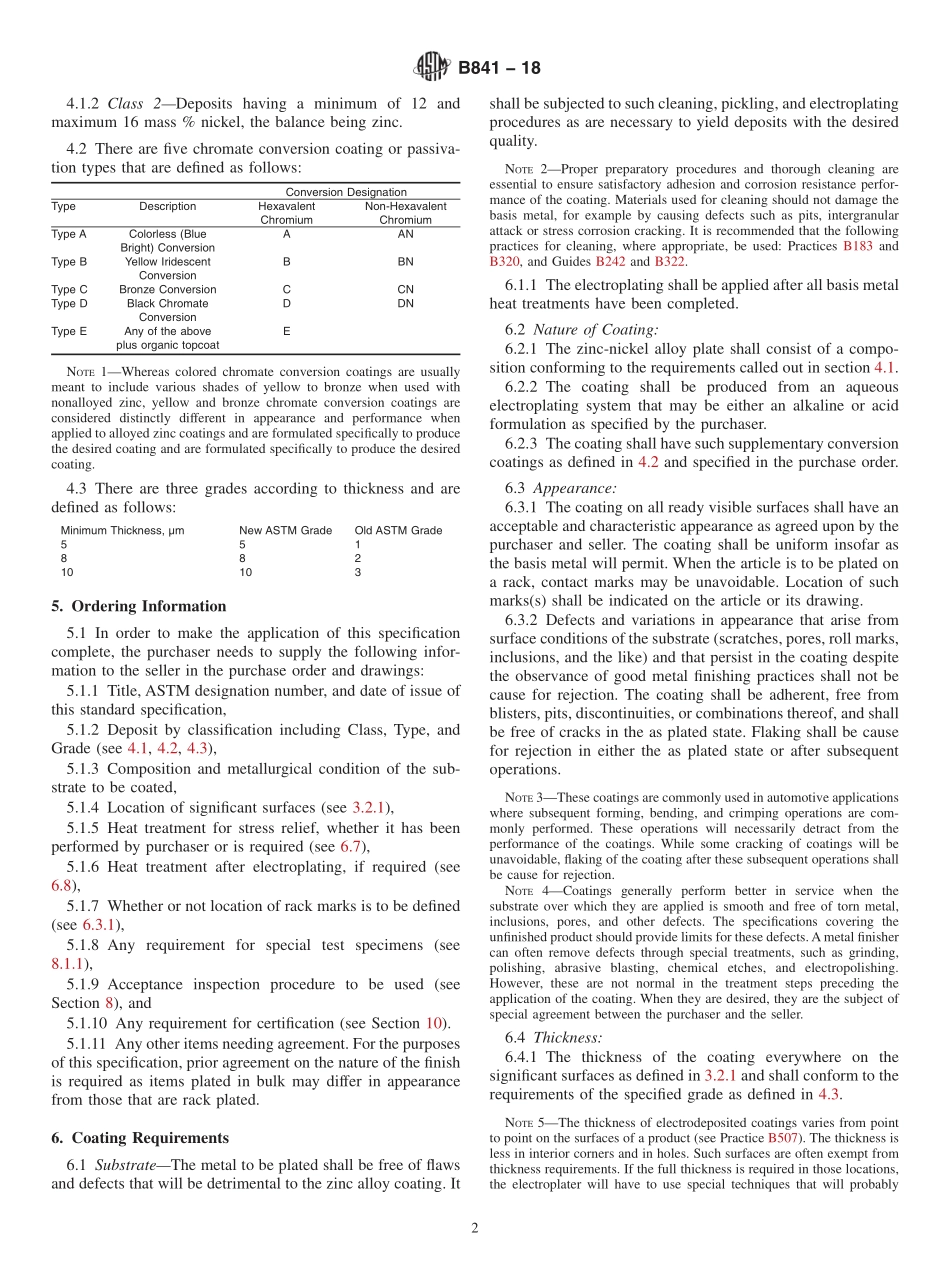

Designation:B841−18StandardSpecificationforElectrodepositedCoatingsofZincNickelAlloyDeposits1ThisstandardisissuedunderthefixeddesignationB841;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoverstherequirementsforelectrode-positedzincnickelalloycoatingsonmetals.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.1.3Thefollowingprecautionarystatementpertainstothetestmethodportiononly,Section8,ofthisspecification:Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafety,health,andenvironmentalpracticesanddeterminetheapplicabilityofregulatorylimitationspriortouse.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2B117PracticeforOperatingSaltSpray(Fog)ApparatusB183PracticeforPreparationofLow-CarbonSteelforElectroplatingB242GuideforPreparationofHigh-CarbonSteelforElec-troplatingB320PracticeforPreparationofIronCastingsforElectro-platingB322GuideforCleaningMetalsPriortoElectroplatingB374TerminologyRelatingtoElectroplatingB487TestMethodforMeasurementofMetalandOxideCoatingThicknessbyMicroscopicalExaminationofCrossSectionB499TestMethodforMeasurementofCoatingThicknessesbytheMagneticMethod:NonmagneticCoatingsonMagneticBasisMetalsB504TestMethodforMeasurementofThicknessofMetal-licCoatingsbytheCoulometricMethodB507PracticeforDesignofArticlestoBeElectroplatedonRacksB568TestMethodforMeasurementofCoatingThicknessbyX-RaySpectrometryB571PracticeforQualitativeAdhesionTestingofMeta...