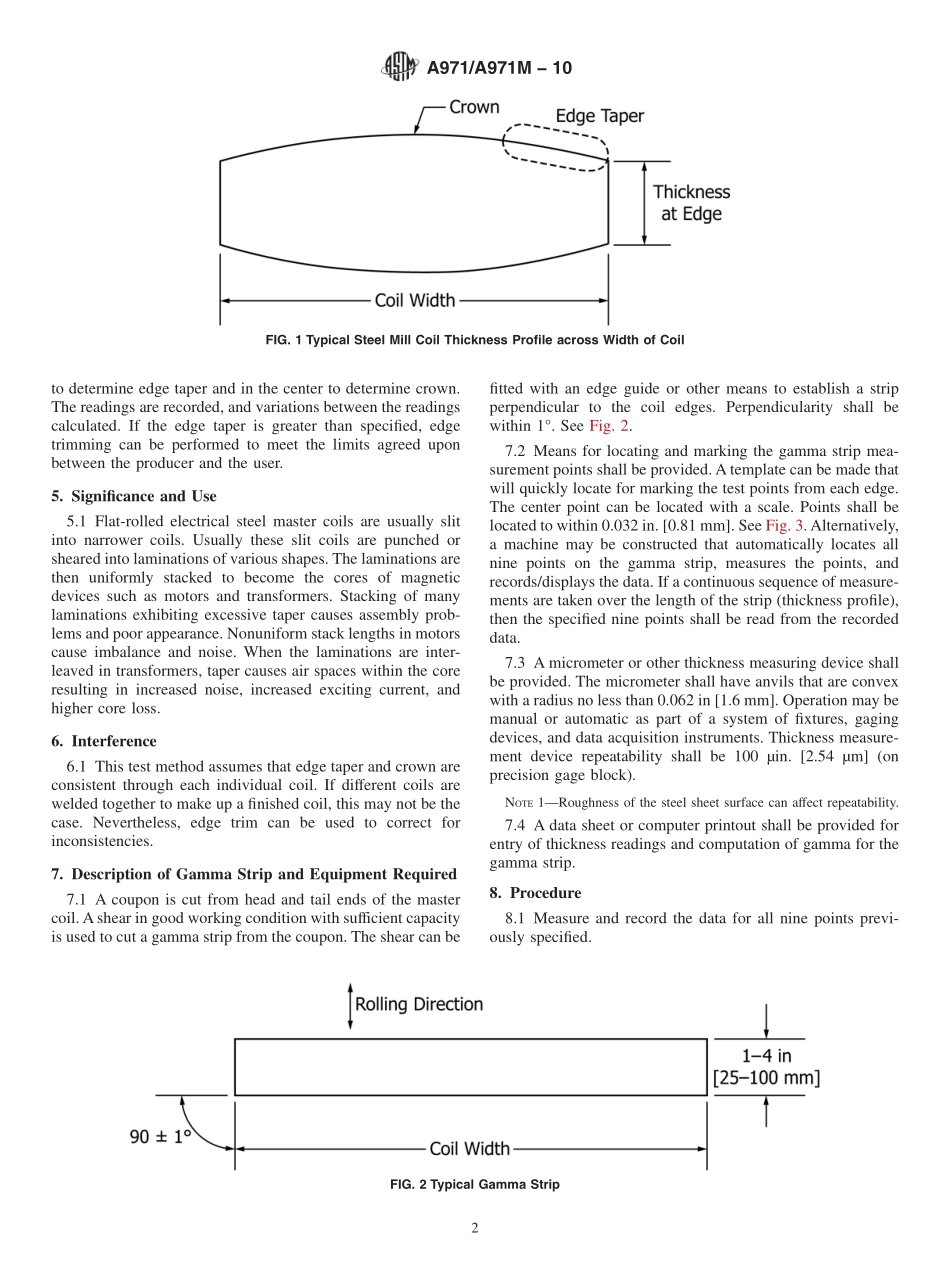

Designation:A971/A971M−10StandardTestMethodforMeasuringEdgeTaperandCrownofFlat-RolledElectricalSteelCoils1ThisstandardisissuedunderthefixeddesignationA971/A971M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodprovidesaprocedureformeasuringedgetaperandcrownofflat-rolledelectricalsteelcoilsasproducedatthesteelmill.1.2Thevaluesandequationsstatedincustomary(cgs-emuandinch-pound)unitsorSIunitsaretoberegardedseparatelyasstandard.Withinthisstandard,theSIunitsareshowninbrackets.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnonconformancewiththisstandard.1.3Thefollowingmaterialspecificationsincluderequire-mentsforedgetaperorcrown:A677,A683,A726,A840,andA876.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2A340TerminologyofSymbolsandDefinitionsRelatingtoMagneticTestingA677SpecificationforNonorientedElectricalSteelFullyProcessedTypesA683SpecificationforNonorientedElectricalSteel,Semi-processedTypesA726SpecificationforCold-RolledMagneticLaminationQualitySteel,SemiprocessedTypesA840SpecificationforFullyProcessedMagneticLamina-tionSteel(Withdrawn2011)3A876SpecificationforFlat-Rolled,Grain-Oriented,Silicon-Iron,ElectricalSteel,FullyProcessedTypes3.Terminology3.1Definitions:Exceptasdefinedasfollows,thesymbolsandterminologyusedinthistestmethodaredefinedinTerminologyA340.3.1.1edgetaperandcrown—thevariationsofthicknessacrossthewidthsofcold-rolledsteelcoils,thatis,perpendicu-lartotherollingdirection.Edgetaperandcrownarenot...