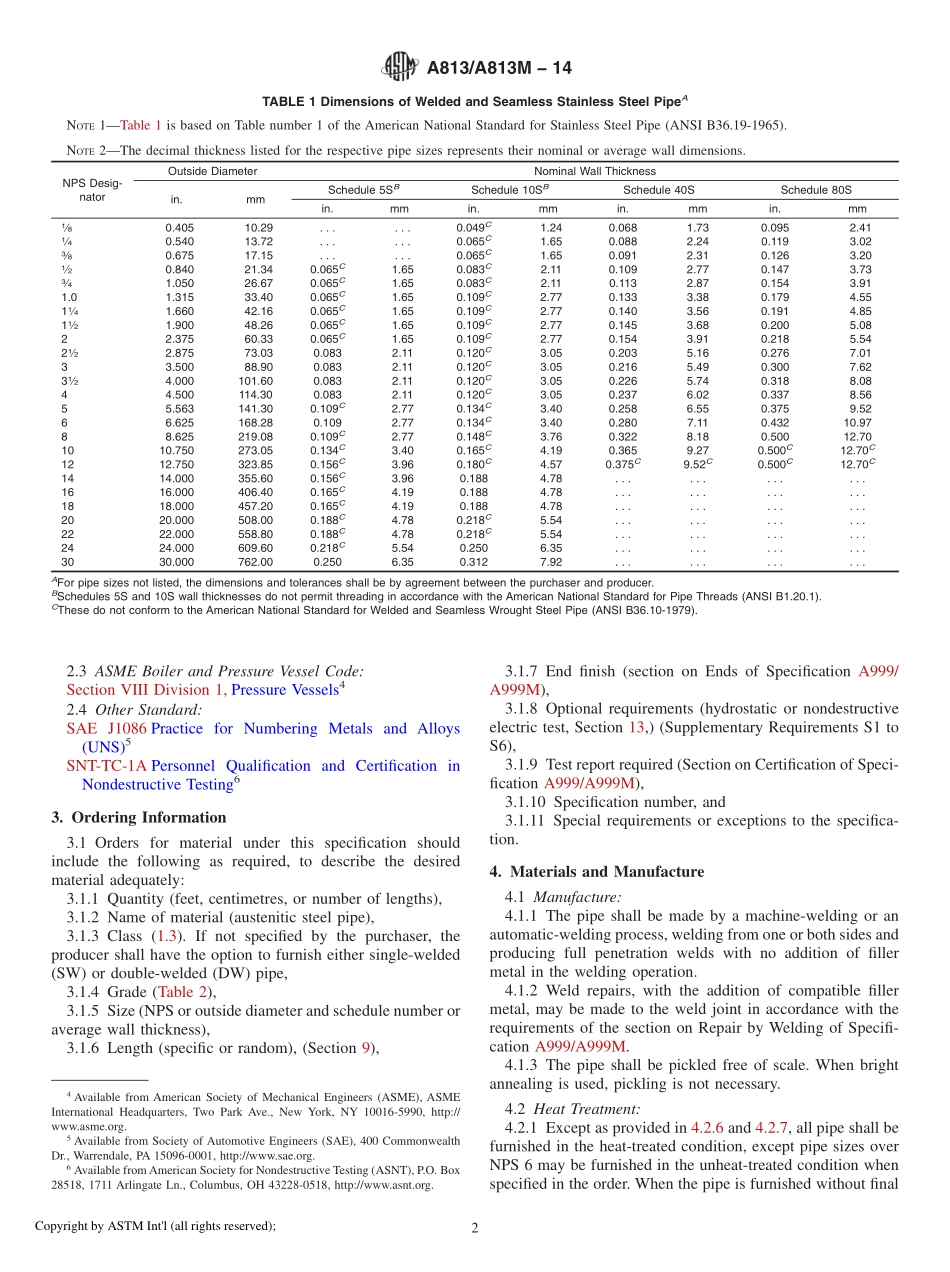

Designation:A813/A813M−14StandardSpecificationforSingle-orDouble-WeldedAusteniticStainlessSteelPipe1ThisstandardisissuedunderthefixeddesignationA813/A813M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisspecificationcoverstwoclassesoffit-upandalignmentqualitystraight-seamsingle-ordouble-weldedaus-teniticsteelpipeintendedforhigh-temperatureandgeneralcorrosiveservice.NOTE1—Whentheimpacttestcriterionforalow-temperatureservicewouldbe15ft·lbf[20J]energyabsorptionor15mils[0.38mm]lateralexpansion,someoftheausteniticstainlesssteelgradescoveredbythisspecificationareacceptedbycertainpressurevesselorpipingcodeswithoutthenecessityofmakingtheactualtest.Forexample,Grades304,304L,and347areacceptedbytheASMEPressureVesselCode,SectionVIIIDivision1,andbytheChemicalPlantandRefineryPipingCode,ANSIB31.3forserviceattemperaturesaslowas−425°F[−250°C]withoutqualificationbyimpacttests.OtherAISIstainlesssteelgradesareusuallyacceptedforservicetemperaturesaslowas−325°F[−200°C]withoutimpacttesting.Impacttestingmay,undercertaincircumstances,berequired.Forexample,materialswithchromiumornickelcontentoutsidetheAISIranges,andformaterialwithcarboncontentexceeding0.10%,arerequiredtobeimpacttestedundertherulesofASMESectionVIIIDivision1whenservicetemperaturesarelowerthan−50°F[−45°C]1.2GradesTP304H,TP304N,TP316H,TP316N,TP321H,TP347H,andTP348HaremodificationsofGradesTP304,TP316,TP321,TP347,andTP348,andareintendedforhigh-temperatureservice.1.3Twoclassesofpipearecoveredasfollows:1.3.1ClassSW—Pipe,single-weldedwithnoadditionoffillermetaland1.3.2ClassDW—Pipe,double-weldedwithnoadditionoffillermetal.1.4Optionalsupplementaryrequirementsareprovidedforpipewhereagreaterdegreeoftestingisdesired.Thesesupplementaryrequirementscallforadditionalteststobemadeand,whendesired,oneormor...