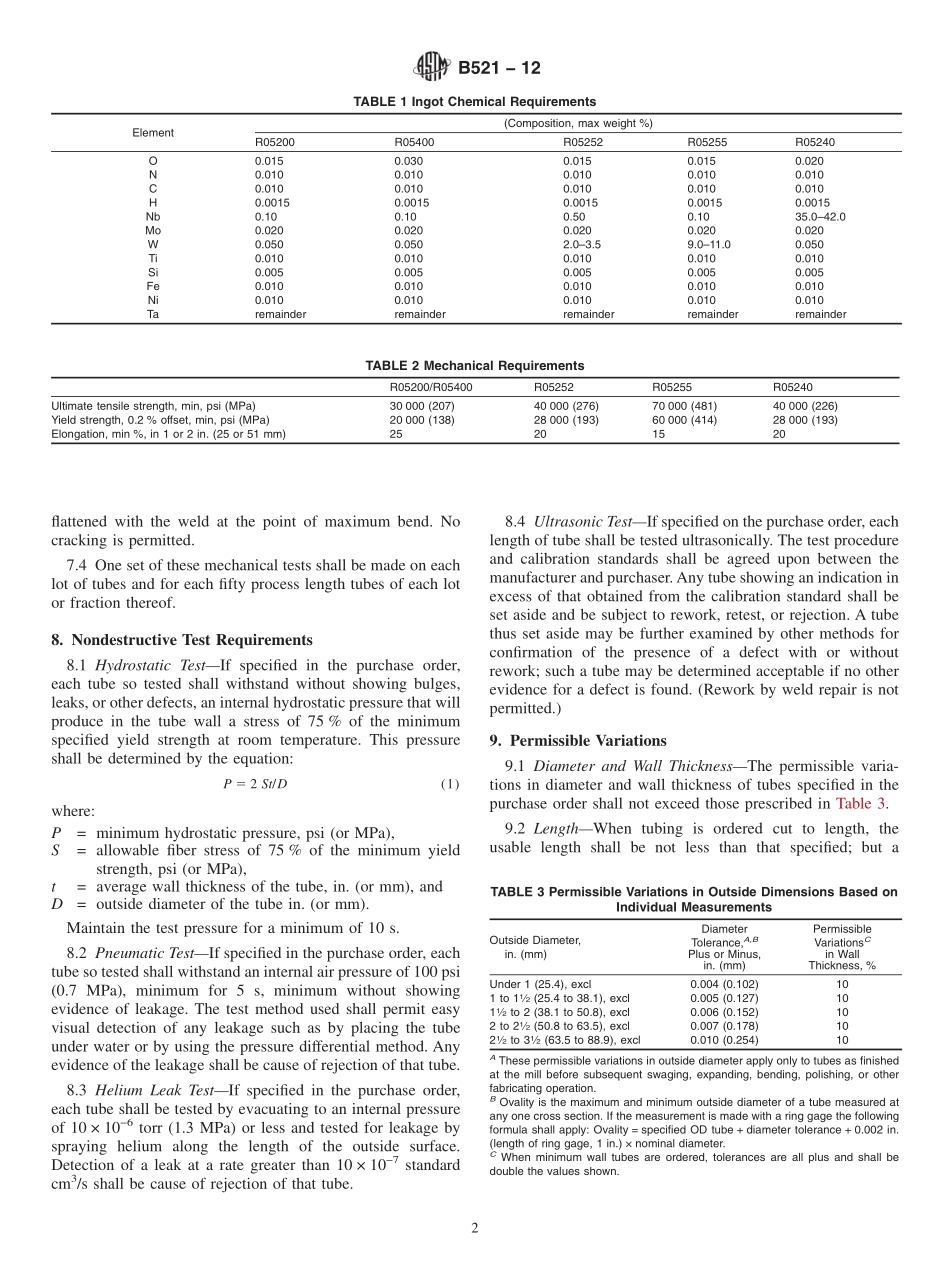

Designation:B521−12StandardSpecificationforTantalumandTantalumAlloySeamlessandWeldedTubes1ThisstandardisissuedunderthefixeddesignationB521;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoverstantalumandtantalumalloyseamlessandweldedtubesofthefollowinggrades:1.1.1UNSGradeR05400—Unalloyedtantalum,powder-metallurgyconsolidation,1.1.2UNSGradeR05200—Unalloyedtantalum,vacuummelted,1.1.3UNSGradeR05252—Tantalum+2.5%tungstenalloy,vacuummelted.1.1.4UNSGradeR05255—Tantalum+10%tungstenalloy,vacuummelted.1.1.5UNSGradeR05240—Tantalumalloy,60%tantalum,40%niobium,electron-beamfurnaceorvacuumarcmelt,orboth.1.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.2.ReferencedDocuments2.1ASTMStandards:2E29PracticeforUsingSignificantDigitsinTestDatatoDetermineConformancewithSpecifications3.Terminology3.1DefinitionsofTermsSpecifictoThisStandard:3.1.1lot—allmaterialproducedfromthesameingotorsinglepowderblend,ofthesamesizeandlastannealedinthesamefurnacecharge.3.1.2processlength—theone-piecelengthofeachtubethatresultsfromtheproductionoperationthatfirstyieldsthetubularform.Samplingandtestingshouldingeneralbebasedonprocesslengthsunlessspecificallystatedotherwise.4.OrderingInformation4.1Ordersformaterialunderthisspecificationshallincludethefollowinginformation:4.1.1Quantity,4.1.2UNSgrade,4.1.3Type(weldedorseamless),4.1.4Dimensions,4.1.5Nondestructivetestrequirements,ifany,and4.1.6Additionstothespecificationandsupplementaryrequirements,ifany.5.MaterialsandManufacture5.1Seamlesstubeshallbemadebyanyseamlessmethodthatwillyieldaproductmeetingtherequirementsofthisspecification.5.2Weldedtubeshallbemadefromflat-rolledproductbyanaut...