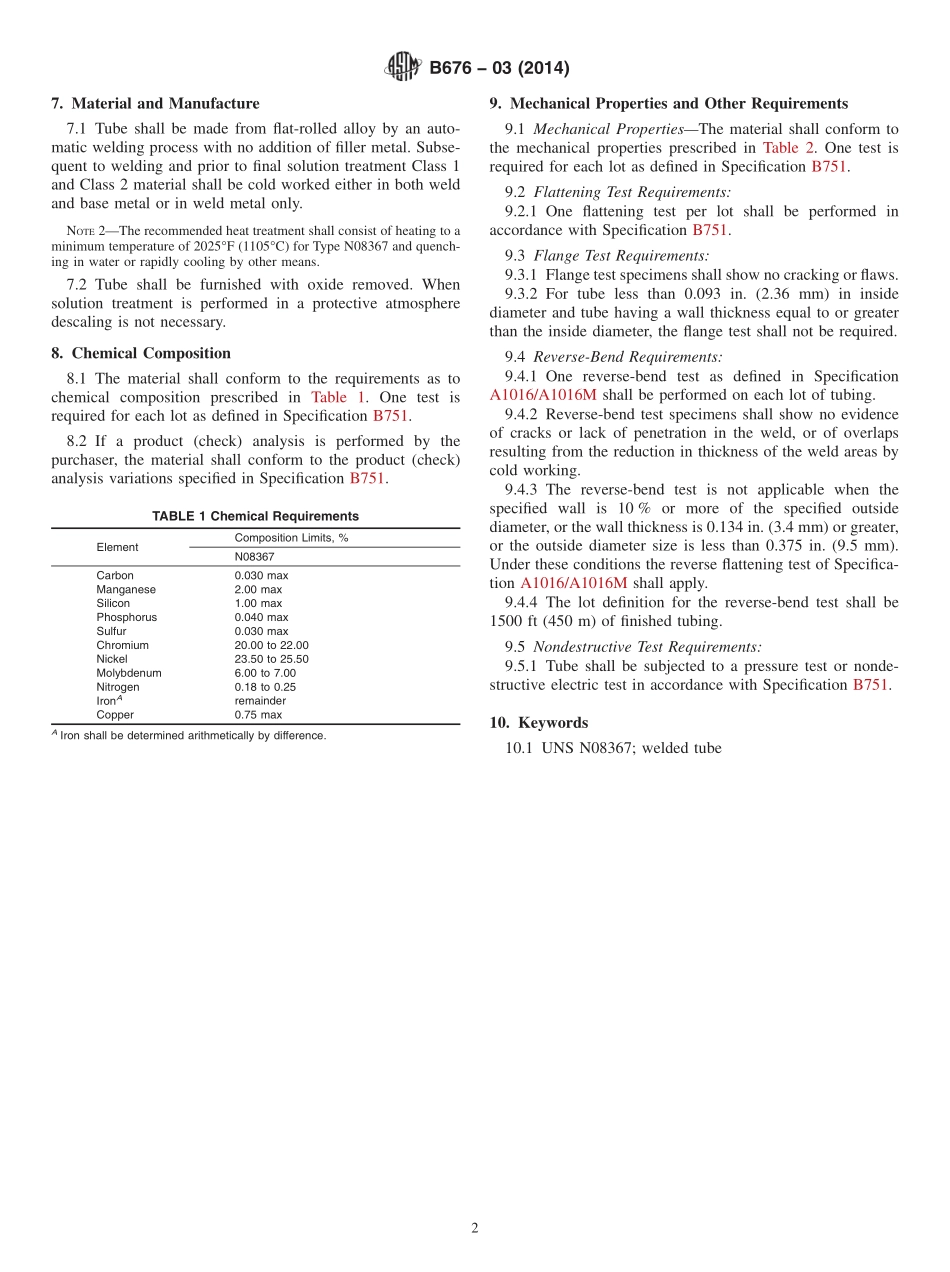

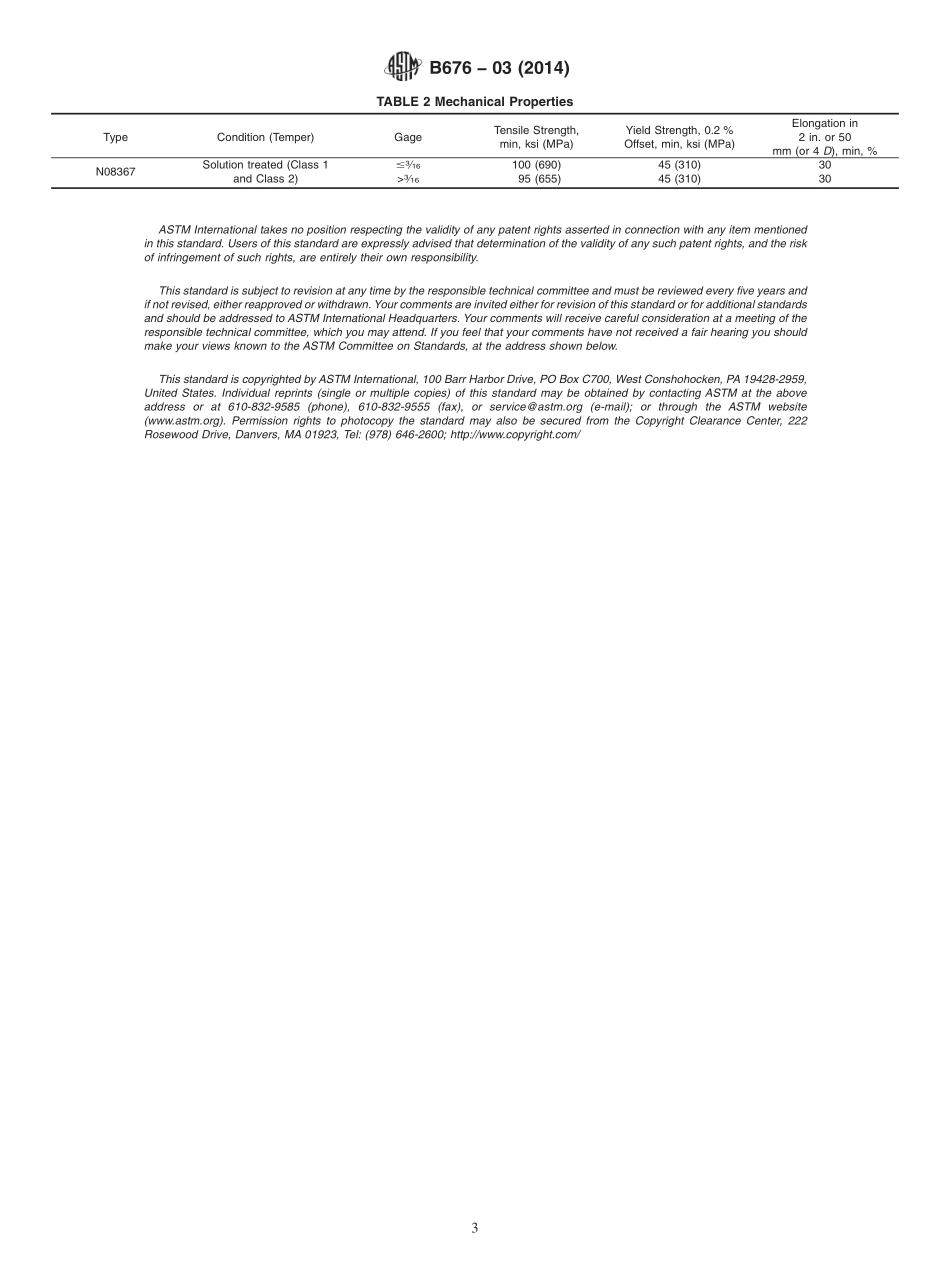

Designation:B676−03(Reapproved2014)StandardSpecificationforUNSN08367WeldedTube1ThisstandardisissuedunderthefixeddesignationB676;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1ThisspecificationcoversUNSN083672weldedtubeforgeneralcorrosionapplications.1.2Thisspecificationcoversoutsidediameterandnominalwalltube.1.2.1Thetubesizescoveredbythisspecificationare1⁄8to5in.(3.2to127mm)inoutsidediameterand0.015to0.320in.(0.38to8.13mm),inclusive,inwallthickness.1.3Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.ItistheresponsibilityoftheuserofthisstandardtobecomefamiliarwithallhazardsincludingthoseidentifiedintheappropriateMaterialSafetyDataSheet(MSDS)forthisproduct/materialasprovidedbythemanufacturer,toestablishappropriatesafetyandhealthpractices,anddeterminetheapplicabilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:3A1016/A1016MSpecificationforGeneralRequirementsforFerriticAlloySteel,AusteniticAlloySteel,andStainlessSteelTubesB751SpecificationforGeneralRequirementsforNickelandNickelAlloyWeldedTubeB899TerminologyRelatingtoNon-ferrousMetalsandAl-loys3.Terminology3.1TermsdefinedinTerminologyB899shallapplyunlessotherwisedefinedinthisstandard.4.GeneralRequirement4.1MaterialfurnishedinaccordancewiththisspecificationshallconformtotheapplicablerequirementsofSpecificationB751unlessotherwiseprovidedherein.5.Classification5.1Class1—Welded,coldworked,solutiontreated,andeachpieceofeachlotsubjectedtooneofthefollowingfourtests:hydrostatic,pneumatic(airunderwater),eddycurrent,orultrasonic.5.2Class2—Welded,coldworked,solution...