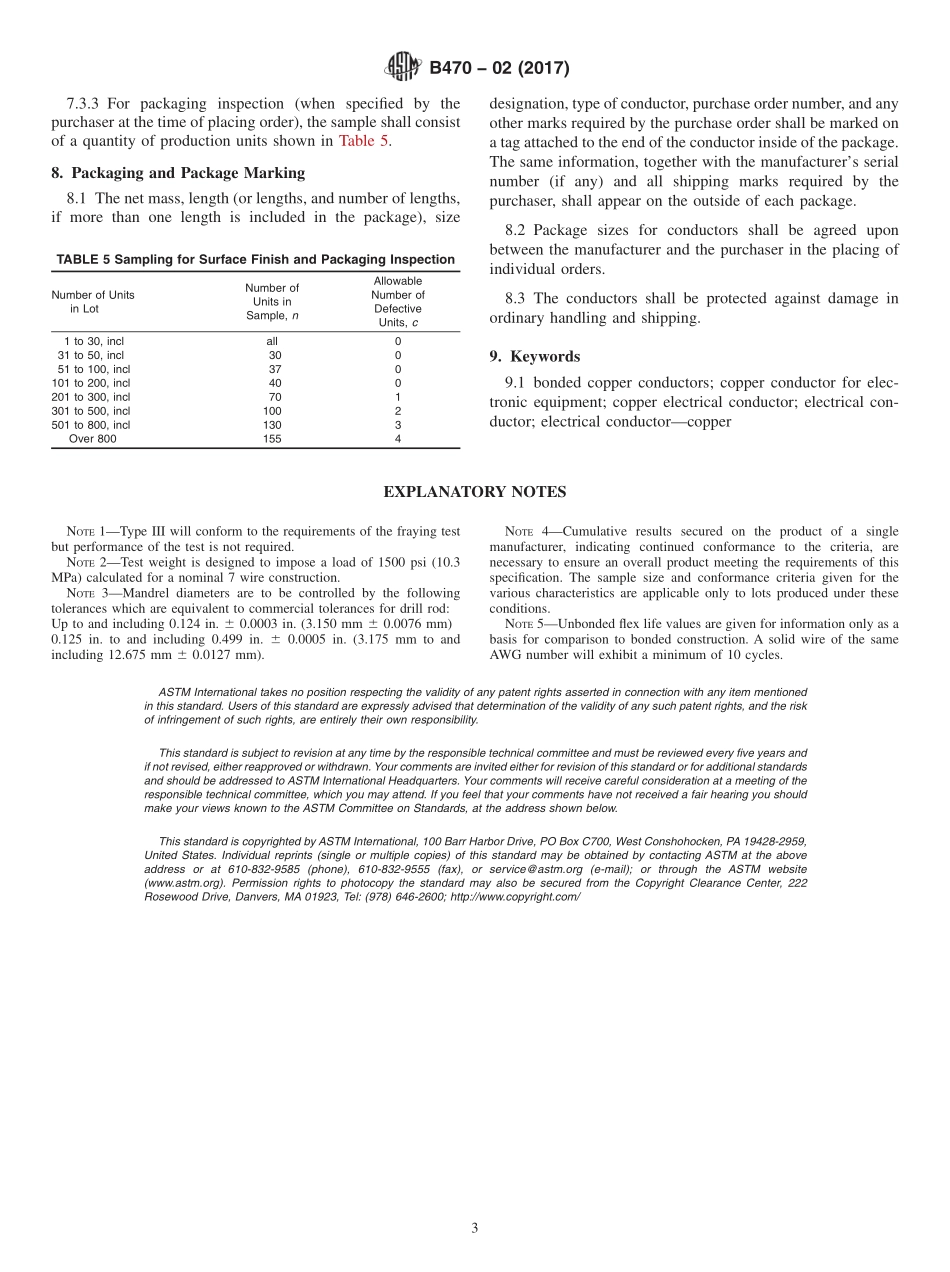

Designation:B470−02(Reapproved2017)StandardSpecificationforBondedCopperConductorsforUseinHookupWiresforElectronicEquipment1ThisstandardisissuedunderthefixeddesignationB470;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoversstrandeduninsulatedbare,tin,ortin-leadalloycoatedcopperconductorsinwhichwiresinthestrandaremetallicallybondedtogetherbytheapplicationofheatoradditionaltin,ortin-leadalloyforuseinhookupwireforelectronicequipment.1.2TheSIvaluesfordensityandresistivityaretoberegardedasstandard.Forallotherproperties,theinch-poundvaluesaretoberegardedasthestandardandtheSIunitsmaybeapproximate.1.3ThehazardcaveatpertainsonlytoSection6ofthisspecification.Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1Thefollowingdocumentsoftheissueineffectatthetimeofreferenceformapartofthisspecificationtotheextentreferencedherein:2.2ASTMStandards:2B3SpecificationforSoftorAnnealedCopperWireB286SpecificationforCopperConductorsforUseinHookupWireforElectronicEquipment3.OrderingInformation3.1Ordersformaterialunderthisspecificationshallincludethefollowinginformation:3.1.1Quantityofeachsize,material,construction,andtype(see4.1),3.1.2Packagesize(see8.1),3.1.3Specialpackagemarkingifrequired(Section8),and3.1.4Placeofinspection(Section7).4.ConductorConstructions4.1Condu...