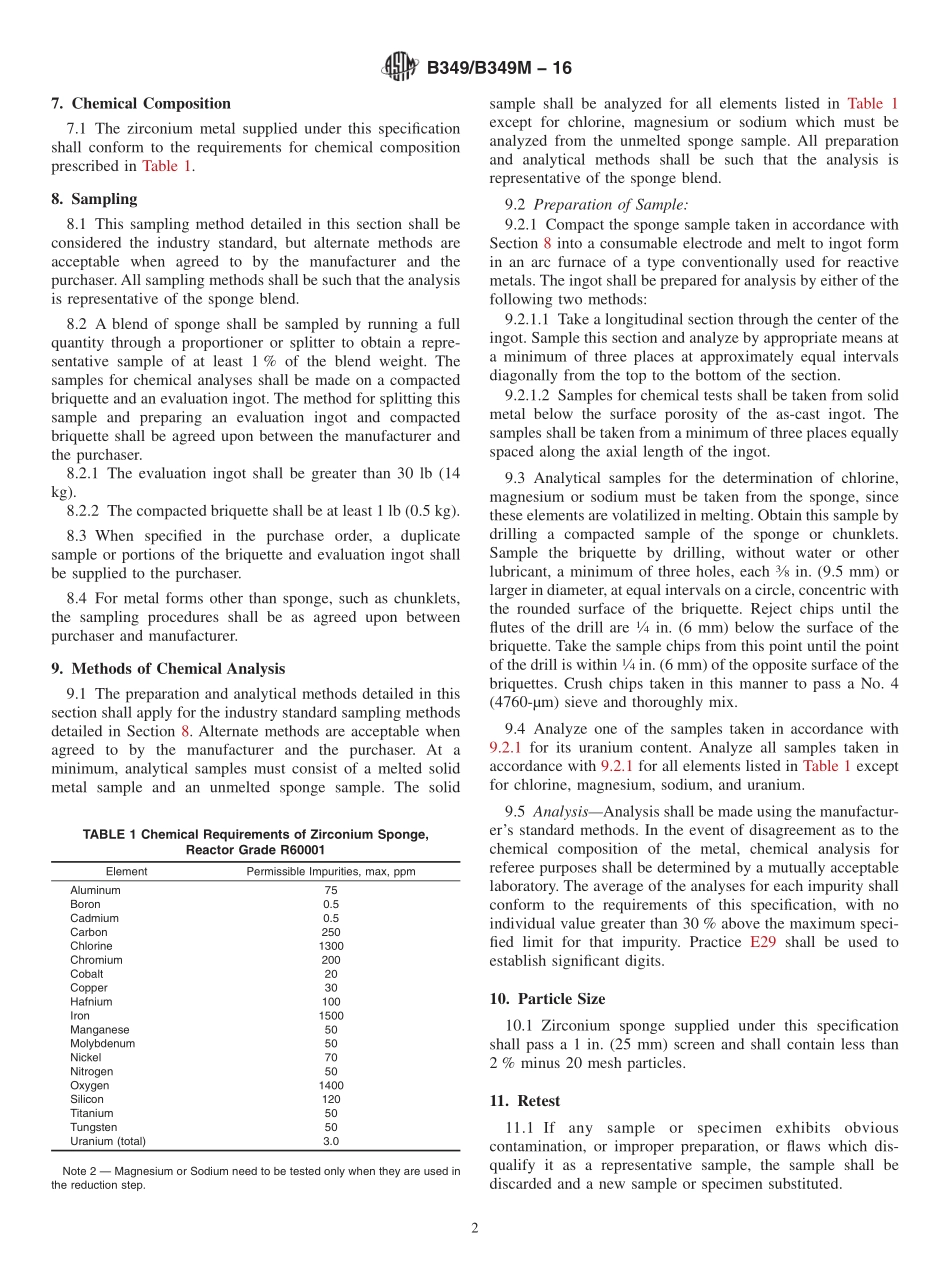

Designation:B349/B349M−16StandardSpecificationforZirconiumSpongeandOtherFormsofVirginMetalforNuclearApplication1ThisstandardisissuedunderthefixeddesignationB349/B349M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoversonegradeofvirginzirconiummetalcommonlydesignatedasspongebecauseofitsporous,sponge-liketexture,butitmayalsotakeotherformssuchaschunklets,suitableforuseinnuclearapplications.1.2Unlessasingleunitisused,forexamplecorrosionmassgaininmg/dm2,thevaluesstatedineitherinch-poundorSIunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemarenotexactequivalents;thereforeeachsystemmustbeusedindependentlyoftheother.SIvaluescannotbemixedwithinch-poundvalues.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2E29PracticeforUsingSignificantDigitsinTestDatatoDetermineConformancewithSpecifications3.Terminology3.1Forms:3.1.1chunklets,n—zirconiummetalproducedfromthereductionofthechloride,usuallybysodium.3.1.1.1Discussion—Inthisprocess,thereducedmetalismeltedanddrippedontoarotatingdisktoformchunklets.3.1.2sponge,n—zirconiummetalproducedfromthereduc-tionofthechloride,usuallybymagnesium.3.1.2.1Discussion—Theprocessisonewherethemetalcondensestothesolidstateanddoesnotmelt.3.2LotDefinition—alotshallconsistofasingleblendproducedatonetime.4.Classification4.1PrimaryzirconiumisfurnishedinonegradedesignatedasReactorGradeR60001,suitablefornuclearapplications.Themaincharacteristicofthereactorgradeisitslowneutroncapturecrosssectionasachievedbyremovalofhafnium.Themanufacturermustuseprocedurestopreventcontamin...