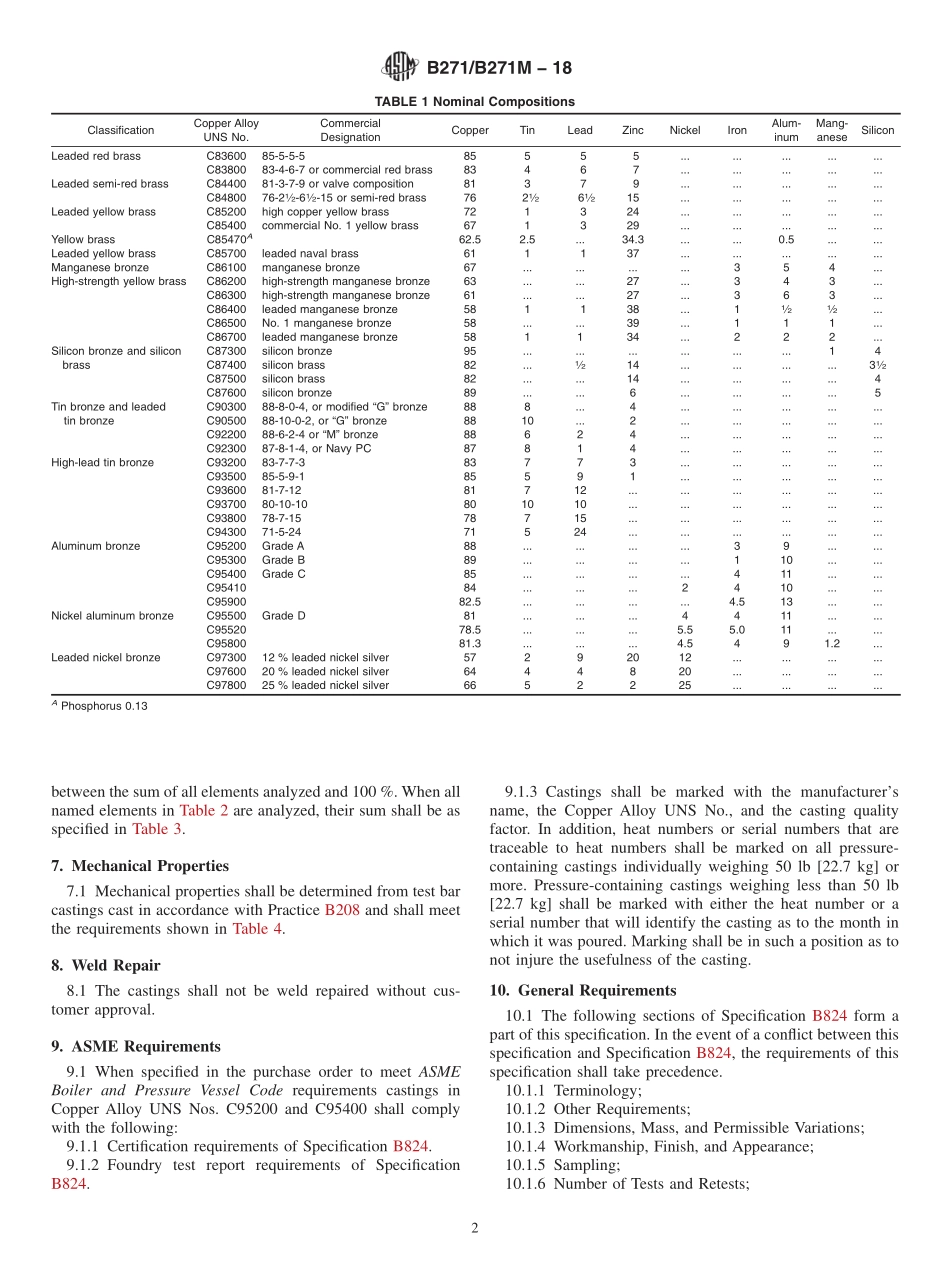

Designation:B271/B271M−18StandardSpecificationforCopper-BaseAlloyCentrifugalCastings1ThisstandardisissuedunderthefixeddesignationB271/B271M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisspecificationestablishesrequirementsforcentrifu-galcastingsofcopper-basealloyshavingthenominalcompo-sitionsshowninTable1.1.2ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.1.3Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ThefollowingdocumentsinthecurrentissueoftheBookofStandardsformapartofthisspecificationtotheextentreferencedherein:2.2ASTMStandards:2B208PracticeforPreparingTensionTestSpecimensforCopperAlloySand,PermanentMold,Centrifugal,andContinuousCastingsB824SpecificationforGeneralRequirementsforCopperAlloyCastingsB846TerminologyforCopperandCopperAlloysE10TestMethodforBrinellHardnessofMetallicMaterials2.3ASMECode:3BoilerandPressureVesselCode3.Terminology3.1DefinitionsoftermsrelatingtocopperalloyscanbefoundinTerminologyB846.4.OrderingInformation4.1Ordersforcentrifugalcastingsunderthisspecificationshouldincludethefollowinginformation:4.1.1Specificationtitle,number,andyearofissue;4.1.2Quantity(lengthornumber)ofcastings;4.1.3CopperAlloyUNSNumber(Table1)andtemper(as-cast,heat-treated,andsoforth);4.1.4Dimensionsordrawingnumberandcondition(as-cast,machined,andsoforth);4.1.5ASMEBoilerandPressure...