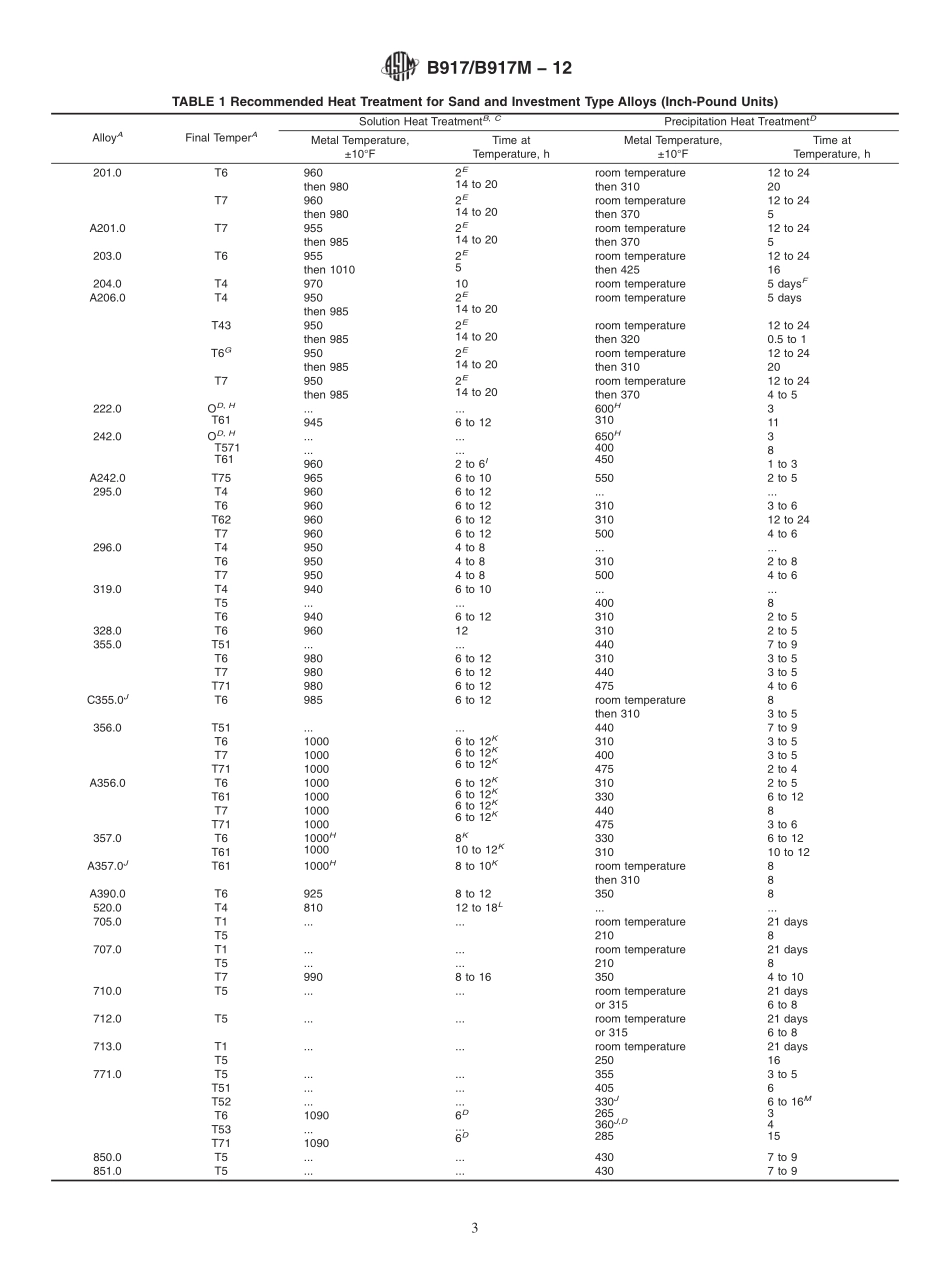

Designation:B917/B917M−12StandardPracticeforHeatTreatmentofAluminum-AlloyCastingsfromAllProcesses1ThisstandardisissuedunderthefixeddesignationB917/B917M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope*1.1Thispracticecovers,whenspecifiedbymaterialspeci-ficationorpurchaseorder,theheattreatmentofaluminumalloycastingsfromallcastingprocesses.1.1.1TheheattreatmentofaluminumalloycastingsusedinspecificaerospaceapplicationsiscoveredinAMS27712andspecificAMS2materialspecifications.1.1.2TheheattreatmentofwroughtaluminumalloysiscoveredinPracticeB918/B918M.1.2ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.1.2.1SIUnits—TheSIunitsareshowninbracketsorinseparatetables.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1Thefollowingdocumentsoftheissueineffectonthedateofmaterialpurchaseformapartofthisspecificationtotheextentreferencedherein:2.2ASTMStandards:3B26/B26MSpecificationforAluminum-AlloySandCast-ingsB108/B108MSpecificationforAluminum-AlloyPermanentMoldCastingsB275PracticeforCodificationofCertainZinc,TinandLeadDieCastingsB557TestMethodsforTensionTestingWroughtandCastAluminum-andMagnesium-AlloyProductsB557MTestMethodsforTensionTestingWroughtandCastAluminum-andMagnesium-AlloyProducts(Metric)B618/B618MSpecificationforAluminum-AlloyInvestmentCastingsB686/B686MSpecificati...