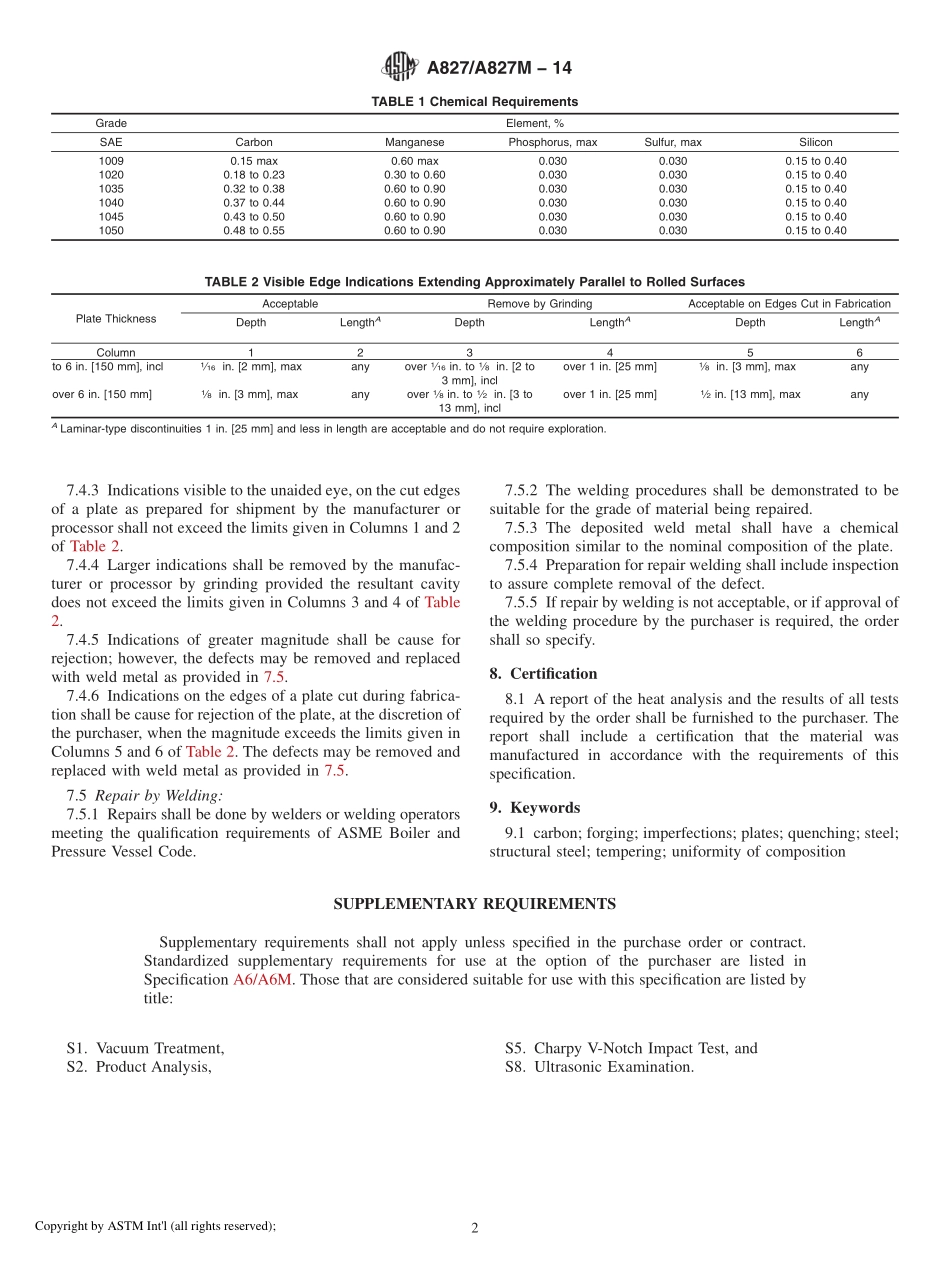

Designation:A827/A827M−14StandardSpecificationforPlates,CarbonSteel,forForgingandSimilarApplications1ThisstandardisissuedunderthefixeddesignationA827/A827M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope*1.1Thisspecificationcoverscarbonsteelplates,forgingquality,intendedforforging,quenching-and-tempering,andsimilarapplicationsinwhichuniformityofcompositionandfreedomfrominjuriousimperfectionsareimportant.1.2Theplatesareavailableinsixgrades,orchemicalcompositions.1.3Whenthesteelistobewelded,itispresupposedthataweldingproceduresuitableforthegradeofsteelandintendeduseorservicewillbeutilized.SeeAppendixX3ofSpecifica-tionA6/A6Mforinformationonweldability.1.4ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.2.ReferencedDocuments2.1ASTMStandards:2A6/A6MSpecificationforGeneralRequirementsforRolledStructuralSteelBars,Plates,Shapes,andSheetPiling2.2ASMECode:3ASMEBoilerandPressureVesselCode,SectionIX3.GeneralRequirementsandOrderingInformation3.1Materialfurnishedunderthisspecificationshallcon-formtotherequirementsofthecurrenteditionofSpecificationA6/A6M,fortheorderedmaterial,unlessaconflictexistsinwhichcasethisspecificationshallprevail.4.MaterialsandManufacture4.1Thesteelshallbekilled.5.ChemicalComposition5.1TheheatanalysisshallconformtotherequirementsfortheapplicablegradelistedinTable1.6.MechanicalPropertyRequirements6.1Theplatesshallnotbesubjecttomechanicalpropertytestingunlessotherwisespecifiedontheorder.7.Quality7.1General—Theplatesshallbefreeofinjuriousimperfec-tionsandshallh...