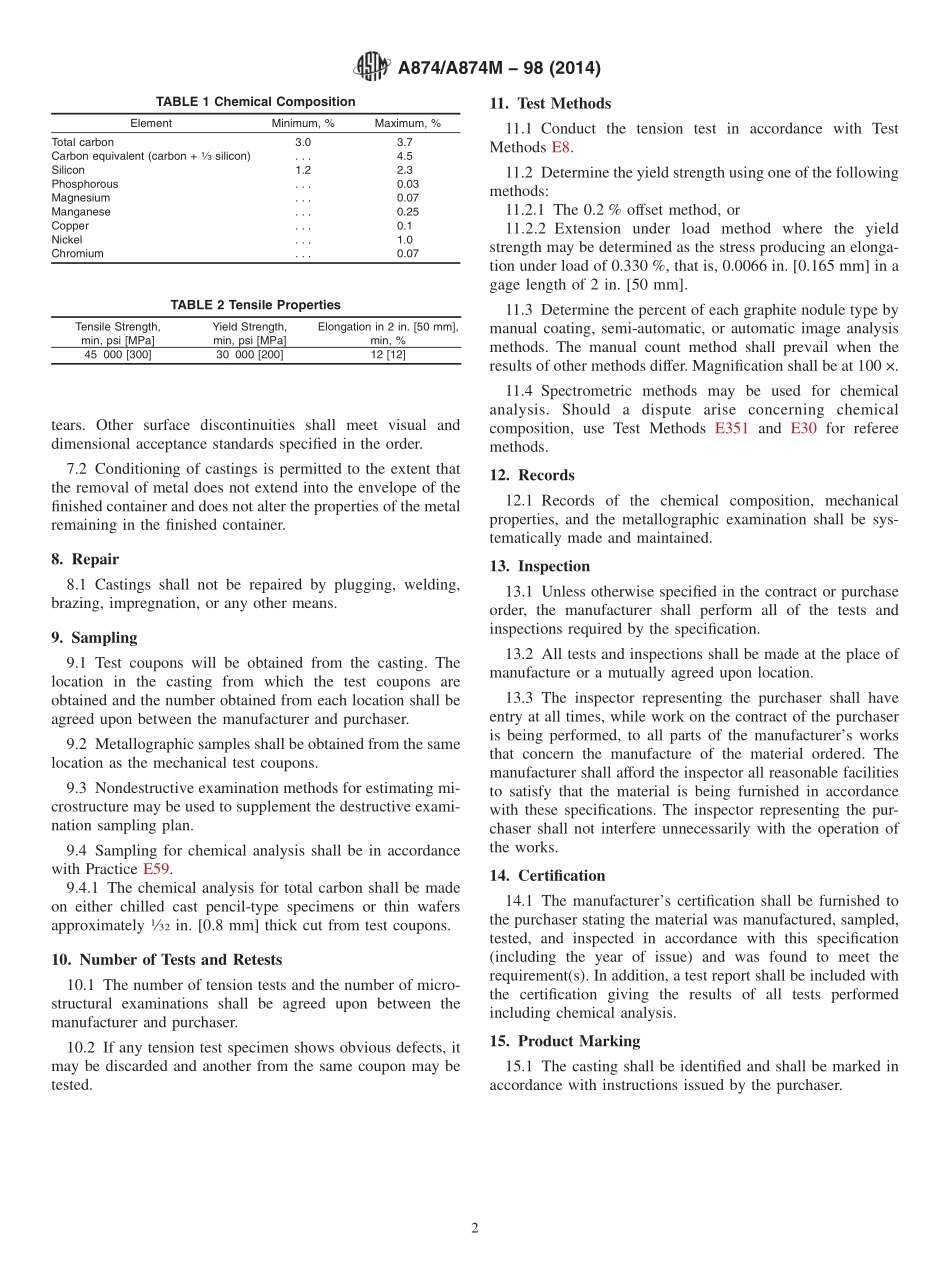

Designation:A874/A874M−98(Reapproved2014)StandardSpecificationforFerriticDuctileIronCastingsSuitableforLow-TemperatureService1ThisstandardisissuedunderthefixeddesignationA874/A874M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoversductileironcastingssuitableforserviceattemperaturesof−40°F[–40°C]andabove.1.2ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.1.3Thefollowingprecautionarystatementpertainsonlytothetestmethodsportion,Section11,ofthisspecification:Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimita-tionspriortouse.2.ReferencedDocuments2.1ASTMStandards:2A247TestMethodforEvaluatingtheMicrostructureofGraphiteinIronCastingsE8TestMethodsforTensionTestingofMetallicMaterialsE30TestMethodsforChemicalAnalysisofSteel,CastIron,Open-HearthIron,andWroughtIron(Withdrawn1995)3E59PracticeforSamplingSteelandIronforDeterminationofChemicalComposition(Withdrawn1996)3E94GuideforRadiographicExaminationE165PracticeforLiquidPenetrantExaminationforGeneralIndustryE351TestMethodsforChemicalAnalysisofCastIron—AllTypesE562TestMethodforDeterminingVolumeFractionbySystematicManualPointCountE689ReferenceRadiographsforDuctileIronCastingsE709GuideforMagneticParticleTesting3.OrderingInformation3.1Ordersformaterialunderthisspecificationshallincludethefollowingapplicableinformation:3.1.1Drawing,catalognumber,orpartidentification,3.1.2Quantity(weightornumberofpieces),3.1.3AS...