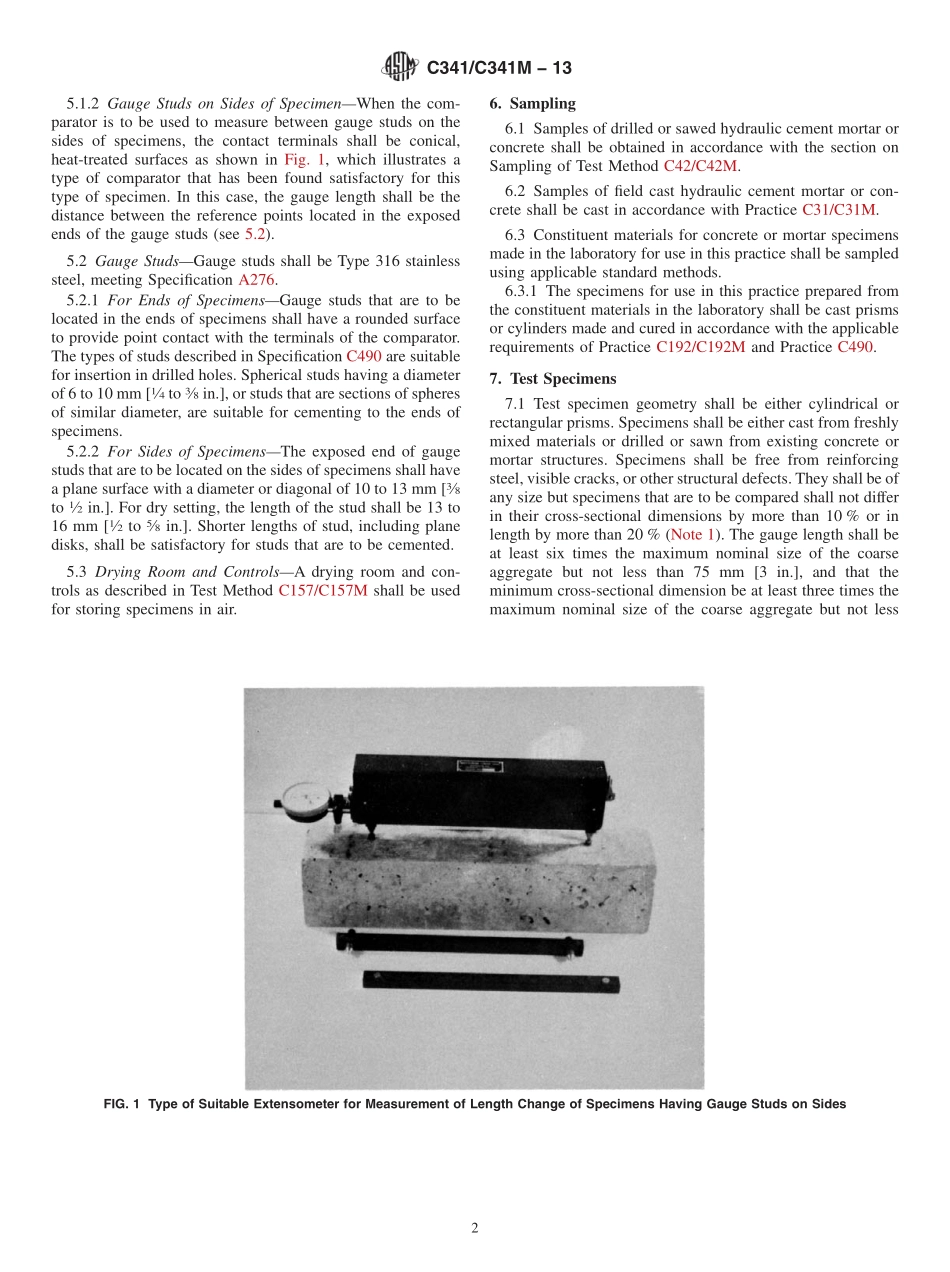

Designation:C341/C341M−13StandardPracticeforPreparationandConditioningofCast,Drilled,orSawedSpecimensofHydraulic-CementMortarandConcreteUsedforLengthChangeMeasurements1ThisstandardisissuedunderthefixeddesignationC341/C341M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thispracticecoverstheproceduresforthepreparationandconditioningofcast,drilled,orsawedspecimensofhydraulic-cementmortarandconcreteforlengthchangeduetocausesotherthanexternallyappliedforces.Itcanbereadilyadapted,ifdesired,tostudiesoflengthchangeinvolvingalternateschedulesorenvironmentaltreatmentotherthanthestandardproceduresprescribedbythispractice.1.2Thevaluesstatedineitherinch-poundunitsorSIunitsshallberegardedseparatelyasstandard.Theunitsstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemmustbeusedindependentlyoftheother,withoutcombininginanyway.Theinch-poundunitsareshowninbrackets.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2A276SpecificationforStainlessSteelBarsandShapesC31/C31MPracticeforMakingandCuringConcreteTestSpecimensintheFieldC42/C42MTestMethodforObtainingandTestingDrilledCoresandSawedBeamsofConcreteC157/C157MTestMethodforLengthChangeofHardenedHydraulic-CementMortarandConcreteC192/C192MPracticeforMakingandCuringConcreteTestSpecimensintheLaboratoryC490PracticeforUseofApparatusfortheDeterminationofLengthChangeofHardenedCementPaste,Mortar,andConcreteC666/C666MTestMethodforResistanceofConcretetoRapidFreezingandThawing3.Terminology3.1Definition3.1.1lengthchange,n—anincreaseordecreaseinalineardimensionofatestspecimen,whichhasbeenca...