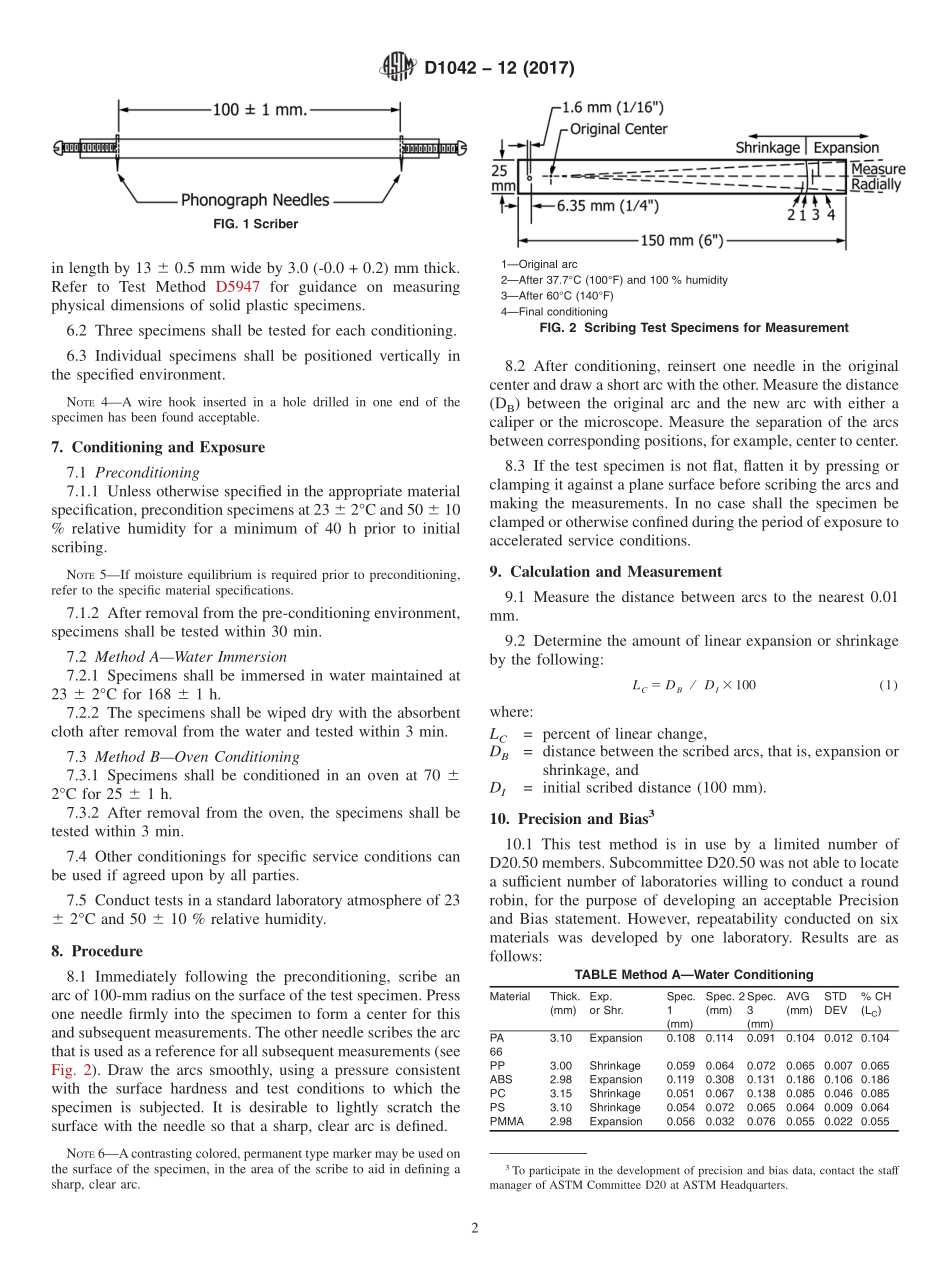

Designation:D1042−12(Reapproved2017)StandardTestMethodforLinearDimensionalChangesofPlasticsCausedbyExposuretoHeatandMoisture1ThisstandardisissuedunderthefixeddesignationD1042;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodisdesignedtoprovideameansformeasuringinplasticspecimensthedimensionalchangessuchasshrinkageorexpansion,developedunderspecificheatandwaterconditionings.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Thevaluesgiveninparenthesesaremathematicalconversionstoinch-poundunitsthatareprovidedforinforma-tiononlyandarenotconsideredstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.NOTE1—ThereisnoknownISOequivalenttothisstandard.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D883TerminologyRelatingtoPlasticsD5947TestMethodsforPhysicalDimensionsofSolidPlasticsSpecimens3.Terminology3.1Definitions:DefinitionsoftermsapplyingtothistestmethodappearinTerminologyD883.4.SignificanceandUse4.1ThistestmethodisintendedonlyasaconvenienttestmethodformeasurementoflineardimensionalchangesinplasticssubjectedtodefinedconditionsoftestasoutlinedinSections7and8.5.Apparatus5.1Scriber,soconstructedthattwosharpneedlepointsarerigidlyseparatedby10060.2mm.Thescriber,asshowninFig.1,consistsoftwosharpsteelneedles,approximately1.5mmindiameter.Theneedlesaretobeinsertedindrilledholeswi...