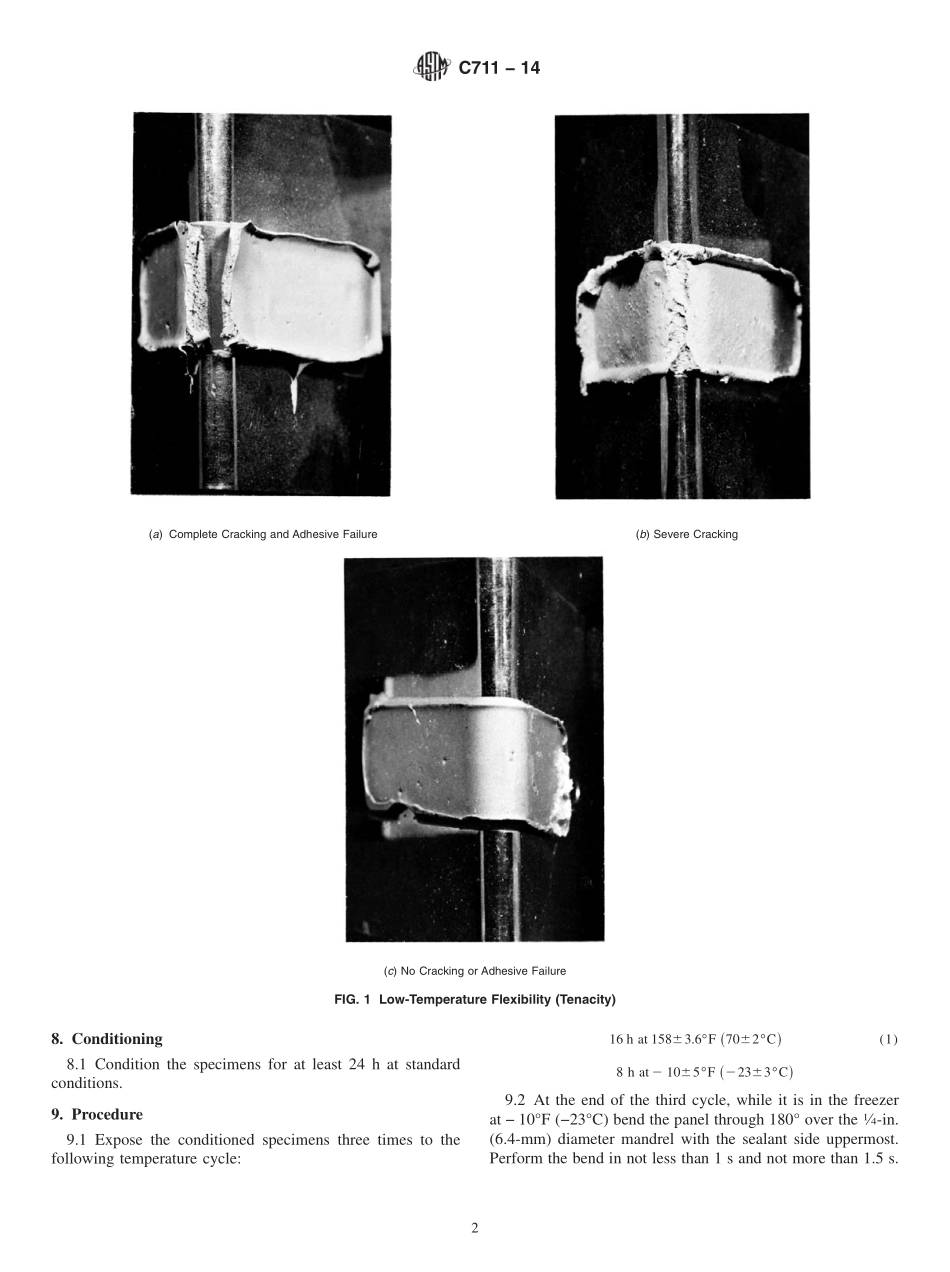

Designation:C711−14StandardTestMethodforLow-TemperatureFlexibilityandTenacityofOne-Part,Elastomeric,Solvent-ReleaseTypeSealants1ThisstandardisissuedunderthefixeddesignationC711;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversdeterminationofthelow-temperatureflexibilityandtenacityofone-part,elastomeric,solvent-releasetypesealantsaftercyclichigh-andlow-temperatureaging.1.2ThesubcommitteewithjurisdictionisnotawareofanysimilarISOstandard.1.3Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2C717TerminologyofBuildingSealsandSealants3.Terminology3.1Definitions—RefertoTerminologyC717fordefinitionsofthefollowingtermsusedinthisTestMethod:elastomer,elastomeric,joint,sealant,solvent-releasesealant,standardconditions.4.SignificanceandUse4.1Thistestmethodisnotintendedtosimulateanactualuseconditionbutitwillgivesomeindicationoftheelastomericpropertiesorflexibilityofabuildingjointsealantatlowtemperature.Itcanservetodifferentiatebetweenelastomer-basedsealantsandsealantsbasedonnonelasticbindersthatcanhardenorembrittleonagingandcrackorloseadhesionwhenflexedatlowtemperature.Inaddition,itcanaidinidentifyingsealantsthathavepoorflexibilitybecausetheyareoverex-tendedandcontainaverylowlevelofelastomericbinderaswellasthosesealantshavingbindersthatwillembrittleatlowtemperature.5.Apparatus5.1AluminumPanels,3,thin,approximately3in.(76mm)wideby5in.(127m...