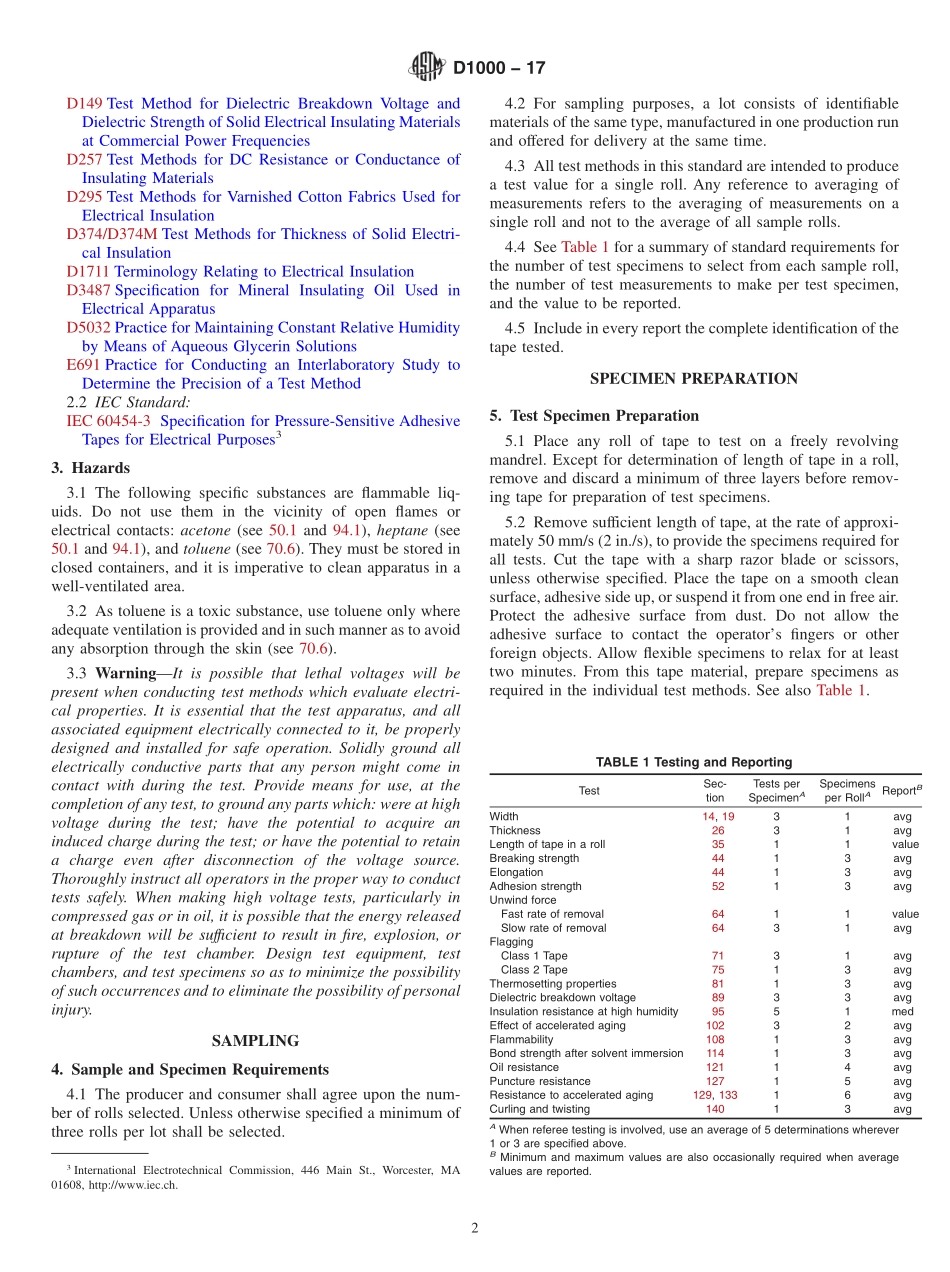

Designation:D1000−17StandardTestMethodsforPressure-SensitiveAdhesive-CoatedTapesUsedforElectricalandElectronicApplications1ThisstandardisissuedunderthefixeddesignationD1000;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thesetestmethodscoverproceduresfortestingpressure-sensitiveadhesive-coatedtapestobeusedaselectri-calinsulation.Thesetapesareclassifiedasfollows:1.1.1Class1—Non-elastomericbackingsmadefrommate-rialssuchas:Paper,flatorcreped,Fabric,uncoatedorcoated,Celluloseesterfilms,Polyethyleneterephthalate(polyester)films,Fluorocarbonpolymerfilms,Compositefilamentfilms,Polyamidefilms,Polyimidefilms,andCombinationsthereof.1.1.2Class2—Elastomericbackingsthatarecharacterizedbybothhighstretchandsubstantialrecovery.Thesebackingsaremadefrommaterialssuchas:Vinylchlorideandco-polymers,Vinylidenechlorideandco-polymers,andPolyethyleneandco-polymers.1.2TestlaminatesofClass1andClass2backingsaccord-ingtoClass1testmethods.1.3Theproceduresappearinthesectionsindicatedbelowandinalphabeticalorder:AdhesionStrengthtoSteelandBackingatRoomTemperature46–53AdhesionStrengthtoSteelandBackingatLowTemperatures46–53BondStrengthAfterSolventImmersion110–115BreakingStrengthandElongationatRoomTemperature37–45BreakingStrengthandElongationatLowTemperatures37–45Conditioning6–8CurlingandTwisting140–146DielectricBreakdownVoltage83–90EffectofAcceleratedAgingonHigh-TemperatureTapes97–103Flagging66–76Flammability104–109Hazards/Precautions3InsulationResistanceatHighHumidity91–96LengthofTapeinaRoll28–36OilResistance116–122PunctureResistance123–128ResistancetoAcceleratedAging(HeatandMoisture)129–139Sampling4SpecimenPreparation5ThermosettingProperties77–82Thickness21–27UnwindForceatRoomTemperature54...