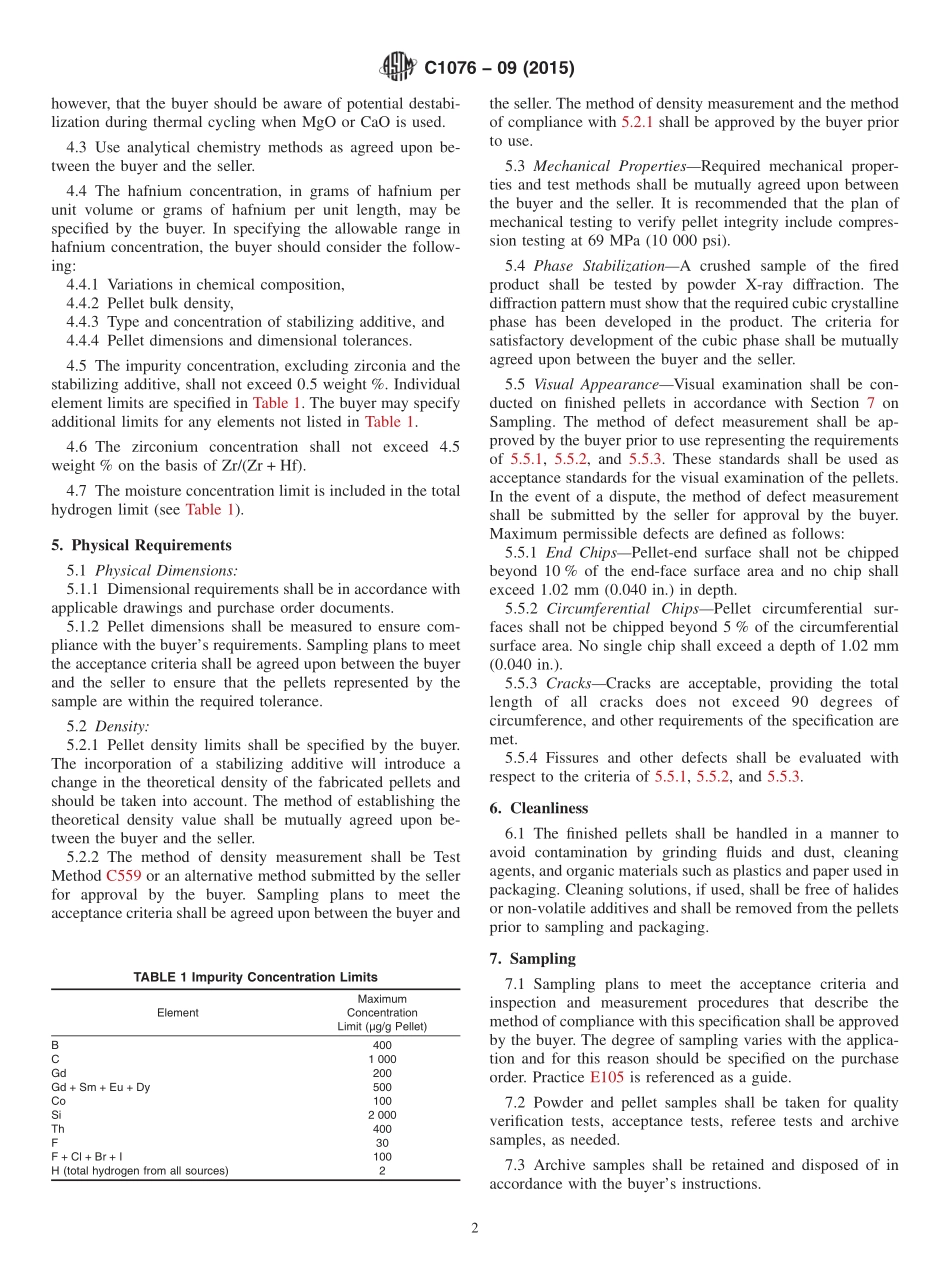

Designation:C1076−09(Reapproved2015)StandardSpecificationforNuclearGradeHafniumOxidePellets1ThisstandardisissuedunderthefixeddesignationC1076;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationappliestopelletsofstabilizedcubichafniumoxideusedinnuclearreactors.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.2.ReferencedDocuments2.1ASTMStandards:2C559TestMethodforBulkDensitybyPhysicalMeasure-mentsofManufacturedCarbonandGraphiteArticlesC859TerminologyRelatingtoNuclearMaterialsC1098SpecificationforNuclear-GradeHafniumOxidePowderE105PracticeforProbabilitySamplingofMaterials2.2ANSIStandard:3ANSI/ASMENQA-1QualityAssuranceRequirementsforNuclearFacilityApplications2.3U.S.GovernmentDocument:4CodeofFederalRegulations,Title10,Part50—Energy(10CFR50)DomesticLicensingofProductionandUtili-zationFacilities3.Terminology3.1Definitions:3.1.1TermsshallbedefinedinaccordancewithTerminol-ogyC859exceptforthefollowing:3.1.2buyer—organizationissuingthepurchaseorder.3.1.3pellet—fabricatedgeometricshapeofstabilizedcubichafniumoxidehavingachemicalcompositionasdescribedinSection4.3.1.4pelletlot—thepelletsproducedfromonehafniumoxidepowderlotusingonesetofprocessparameters.Pelletlotsizeshallbeagreeduponbetweenthesellerandthebuyer.3.1.5phasetransformation—rearrangementoftheatomicorderingofacrystallinelatticeasamaterialiscycledthroughacriticaltransformationorinversiontemperature.Thechangefromonecrystallinephasetoanothermaybeaccompaniedbyavolumechangethatcouldleadtocracksordefectsinarticlesfabricatedfromsuchmaterials.5,63.1.6powderlot—aspecifiedquantityofhafniumoxidepowderwithstabilizingadditive,blendedtogethersuchthatsamplestakeninaccordancewithSection7canbeconsideredasrepresentativeoftheentirequantity.3.1....