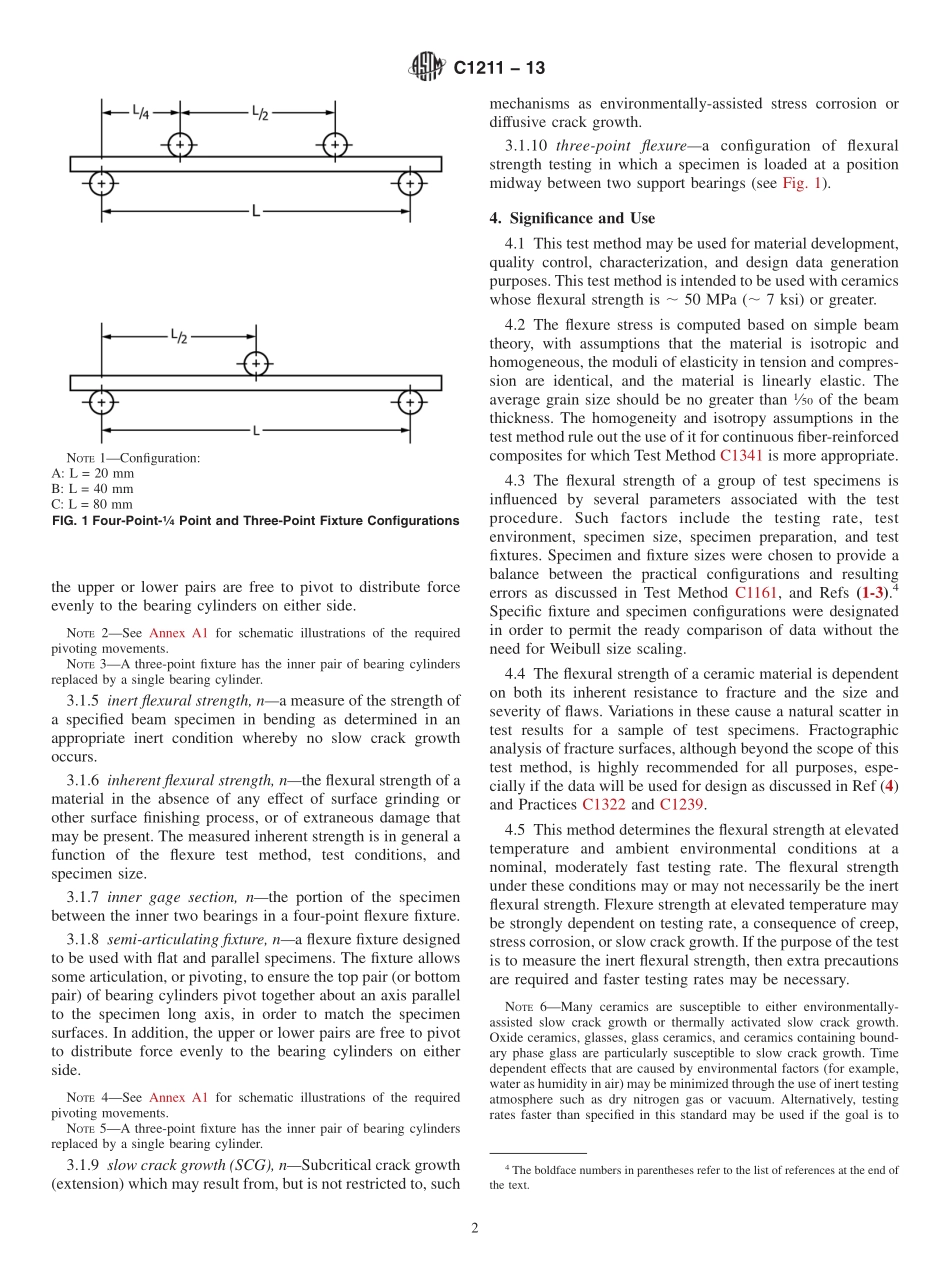

Designation:C1211−13StandardTestMethodforFlexuralStrengthofAdvancedCeramicsatElevatedTemperatures1ThisstandardisissuedunderthefixeddesignationC1211;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversdeterminationoftheflexuralstrengthofadvancedceramicsatelevatedtemperatures.2Four-point-1⁄4pointandthree-pointloadingswithprescribedspansarethestandardasshowninFig.1.Rectangularspecimensofprescribedcross-sectionareusedwithspecifiedfeaturesinprescribedspecimen-fixturecombinations.Testspecimensmaybe3by4by45to50mminsizethataretestedon40mmouterspanfour-pointorthree-pointfixtures.Alternatively,testspecimensandfixturespanshalfortwicethesesizesmaybeused.Thetestmethodpermitstestingofmachinedoras-firedtestspecimens.Severaloptionsformachiningpreparationareincluded:applicationmatchedmachining,customaryprocedures,oraspecifiedstandardprocedure.Thistestmethoddescribestheapparatus,specimenrequirements,testprocedure,calculations,andreportingre-quirements.Thetestmethodisapplicabletomonolithicorparticulate-orwhisker-reinforcedceramics.Itmayalsobeusedforglasses.Itisnotapplicabletocontinuousfiber-reinforcedceramiccomposites.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:3C1161TestMethodforFlexuralStrengthofAdvancedCeramicsatAmbientTemperatureC1239PracticeforReportingUniaxialStrengthDataandEstimatingWeibullDistributionParametersforAdvancedCeramicsC1322PracticeforFractographyandCharacterizationofFractureOriginsinAdvancedCeram...