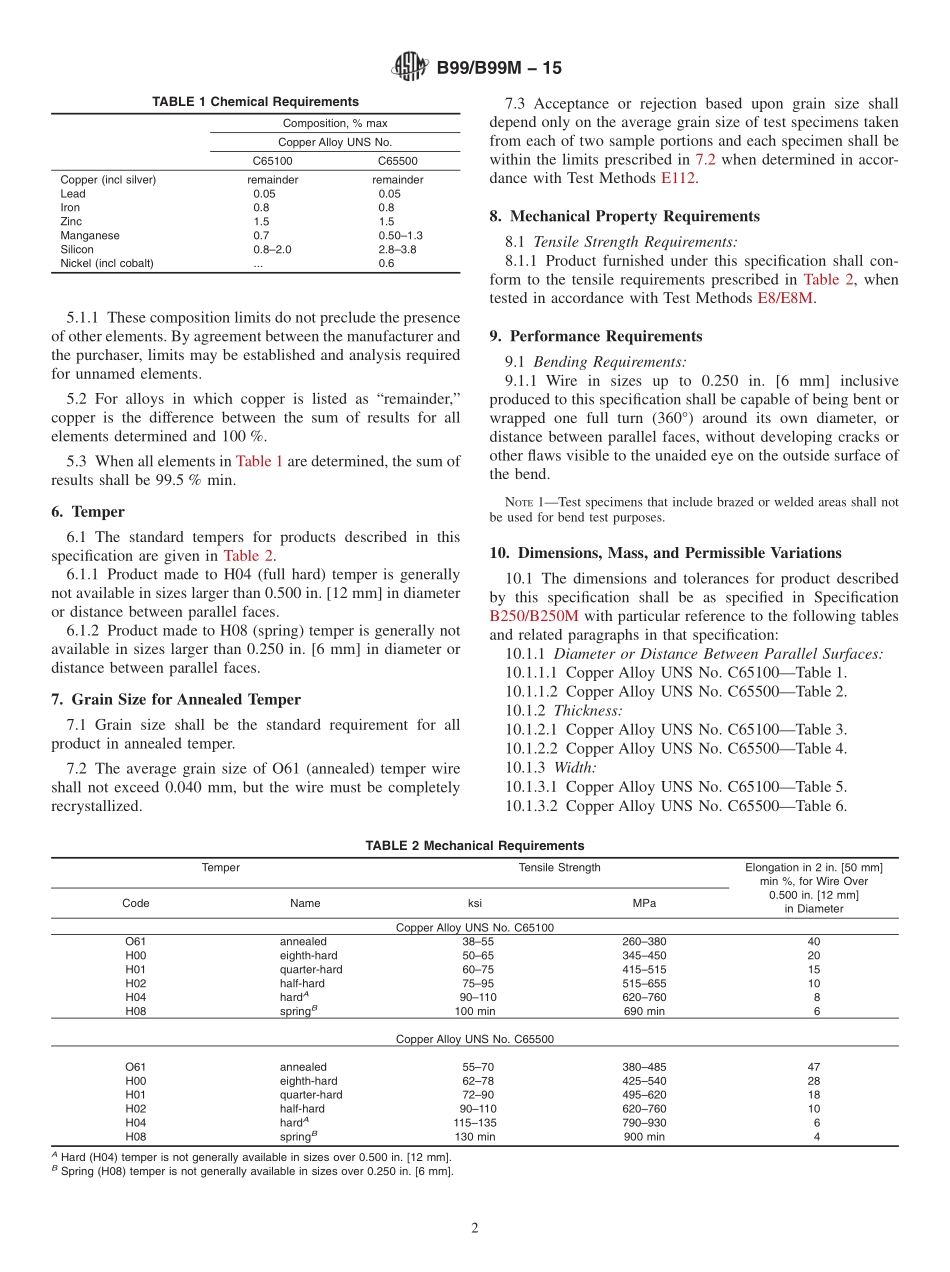

Designation:B99/B99M−15StandardSpecificationforCopper-SiliconAlloyWireforGeneralApplications1ThisstandardisissuedunderthefixeddesignationB99/B99M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope*1.1Thisspecificationestablishestherequirementsforround,rectangular,andsquarewireforgeneralapplicationsotherthanforelectricaltransmissioncable.Thealloysin-volvedareUNSNos.C65100andC65500.1.2Units—Thevaluesstatedineitherinch-poundunitsorSIunitsaretoberegardedseparatelyasstandard.Withinthetext,SIunitsareshowninbrackets.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnonconformancewiththestandard.2.ReferencedDocuments2.1ASTMStandards:2B250/B250MSpecificationforGeneralRequirementsforWroughtCopperAlloyWireE8/E8MTestMethodsforTensionTestingofMetallicMa-terialsE62TestMethodsforChemicalAnalysisofCopperandCopperAlloys(PhotometricMethods)(Withdrawn2010)3E112TestMethodsforDeterminingAverageGrainSizeE478TestMethodsforChemicalAnalysisofCopperAlloys3.GeneralRequirements3.1ThefollowingsectionsofSpecificationB250/B250Mconstituteapartofthisspecification.3.1.1Terminology,3.1.2MaterialsandManufacture,3.1.3Workmanship,Finish,andAppearance,3.1.4Sampling,3.1.5NumberofTestsandRetests,3.1.6SpecimenPreparation,3.1.7TestMethods,3.1.8SignificanceofNumericalLimits,3.1.9Inspection,3.1.10RejectionandRehearing,3.1.11Certification,3.1.12TestReport,3.1.13PackagingandPackageMarking,and3.1.14SupplementaryRequirements.3.2Inaddition,whenasectionwithatitleidenticaltothatreferencedin3.1,above,appearsinthisspecification,itcontainsadditionalrequirementswhichsupplementthoseap-pearinginSpecificationB250/B250M.4.OrderingInformation...