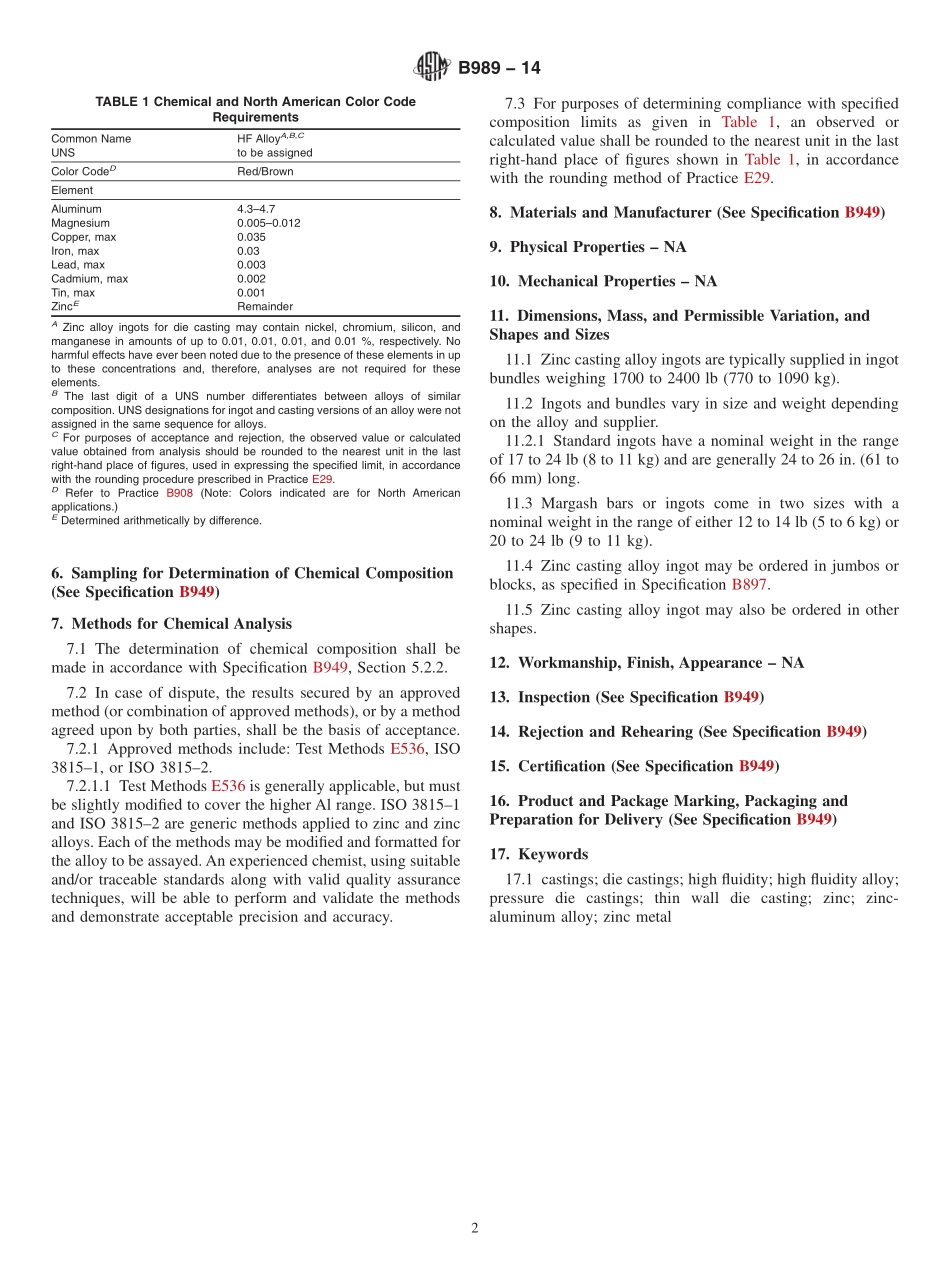

Designation:B989−14StandardSpecificationforHighFluidity(HF)Zinc-AluminumAlloyinIngotFormforThinWallDieCastings1ThisstandardisissuedunderthefixeddesignationB989;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoversacommercialzinc-aluminumalloyiningotformforremeltingforthemanufactureofthinwallpressurediecastingsasdesignatedandspecifiedinTable1.1.2Systemsofnomenclatureusedtodesignatezincandzinc-aluminum(ZA)alloysusedforcastingaredescribedinAppendixX1.1.3Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.ItistheresponsibilityoftheuserofthisstandardtobecomefamiliarwithallhazardsincludingthoseidentifiedintheappropriateMaterialSafetyDataSheet(MSDS)forthisproduct/materialasprovidedbythemanufacturer,toestablishappropriatesafetyandhealthpractices,anddeterminetheapplicabilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1Thefollowingdocumentsoftheissueineffectondateoforderacceptanceformapartofthisspecificationtotheextentreferencedherein:2.2ASTMStandards:2B897SpecificationforConfigurationofZincandZincAlloyJumbo,Block,HalfBlock,andSlabIngotB899TerminologyRelatingtoNon-ferrousMetalsandAl-loysB908PracticefortheUseofColorCodesforZincCastingAlloyIngotB949SpecificationforGeneralRequirementsforZincandZincAlloyProductsE29PracticeforUsingSignificantDigitsinTestDatatoDetermineConformancewithSpecificationsE527PracticeforNumberingMetalsandAlloysintheUnifiedNumberingSystem(UNS)E536TestMethodsforChemicalAnalysisofZincandZincAlloys2.3ISOStandards:3ISO3815–1Zincandzincalloys—Part1:Analysisofsolidsamplesbyopticalemissionspectrometr...