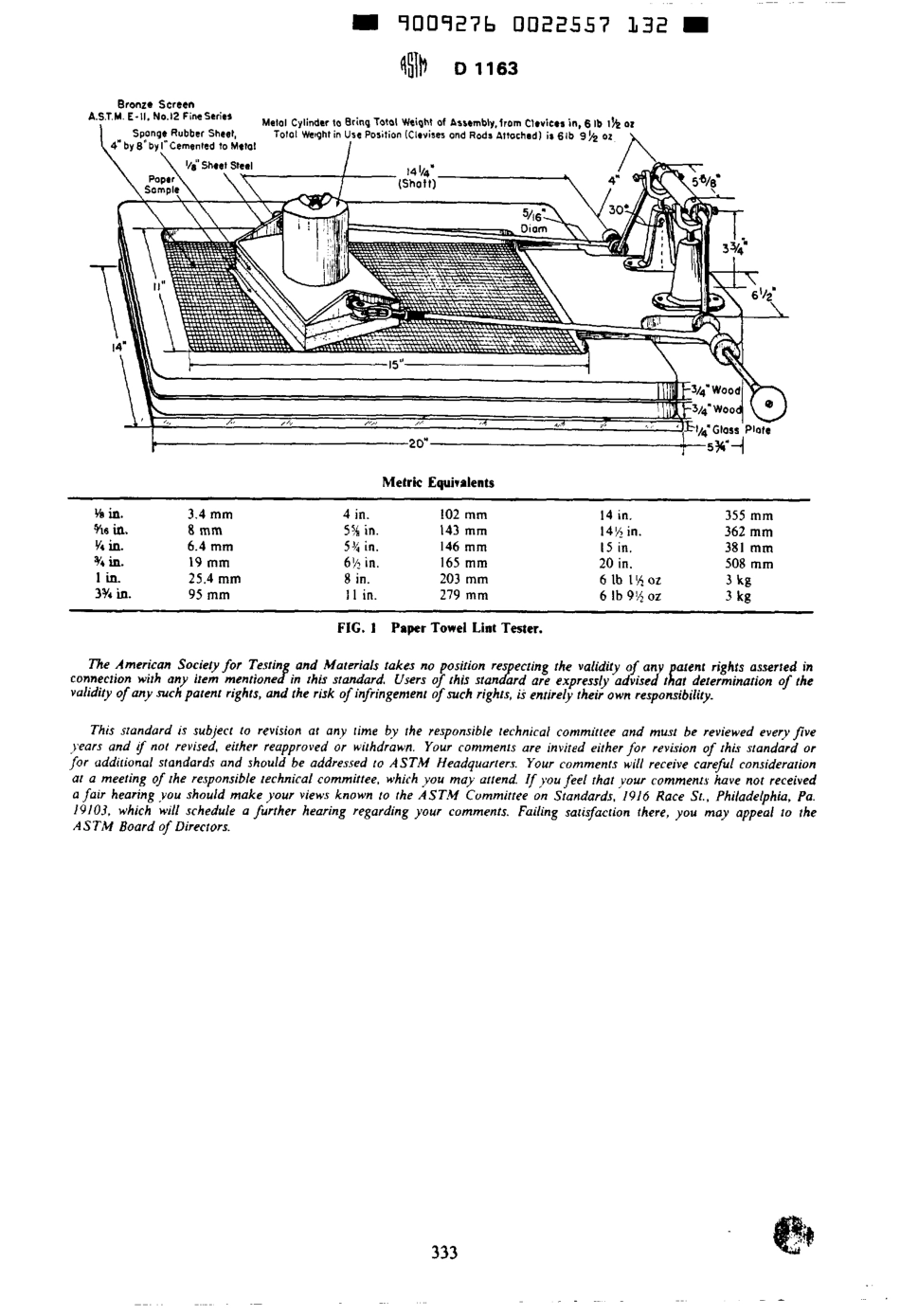

900927b00225562TbDesignation:D1163-53(Reapproved1968)StandardTestMethodforLINTOFPAPERTOWELS1ThisStandardisissuedunderthefixeddesignationD1163;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.1.Scope1.1Thismethodcoversthedeterminationoftheamountoflintremovedfrompapertowelsbythedefinedprocedure.2.Apparatus2.1Theapparatus,illustratedschematicallyinFig.I,shallconformtotherequirementsastothematerialsanddimensionsshowntherein.3.TestSpecimens3.1Thetestspecimensshallberectangularsheetsofpapertowels,4%to5by8%to9in.(108to127by210to228mm)indimensions.3.2ThetestspecimensshallbetakenfromsamplesobtainedinaccordancewithASTMMethodD585,SamplingandAcceptingaSingleLotofPaper,Paperboard,Fiber-board,orRelatedProduct2andshallbecondi-tionedinaccordancewithASTMMethodD685,ConditioningPaperandPaperProductsforTesting.'4.Procedure4.1Makethetestinanatmospherecondi-tionedinaccordancewithMethodD685.NOTEI-Theabradingoperationsshouldbeconductedinstillairsothatlintisnotcarriedawaybyconstantortransientaircurrents.4.2Besurethattheentireapparatusiscleananddry.4.3Placetwospecimens,edgescoinciding,evenlyonthescreenunderthebottomrubberoftherubberassembly,withanapproxi-matelyevenspecimenmargin%to1in.(6.4to25.4mm)widearoundtheedgeoftherubber.Paperspecimensonly,neverrubber,shouldbeincontactwiththescreen.Itisseldomnecessarytofastenthepaperspecimeninplace,butifthespecimendoesshowanytendencytoslipoutofalignmentundertherubber,itmaybeheldinplacebycommonpinsthroughthespecimenmarginintothesideoftherubber.4.4Turnthecrankfivefullturns,attherateofoneturnper0.9to1.1s.Thismovestheweightedrubberandspecimenbackandforthacrossthescreen.4.5Removethespecimenandpresentafreshpapersurfacetothescreen(eithertheothersideofthefirstspecimenorafreshspecimen).Repeattheprocedurein4.4.4.6Repeattheprocedurein4.4and4.5untilatotalof32papersurfaceshavebeensubjectedtotheprescribedrubbingagainstthescreen.4.7Uponcompl...