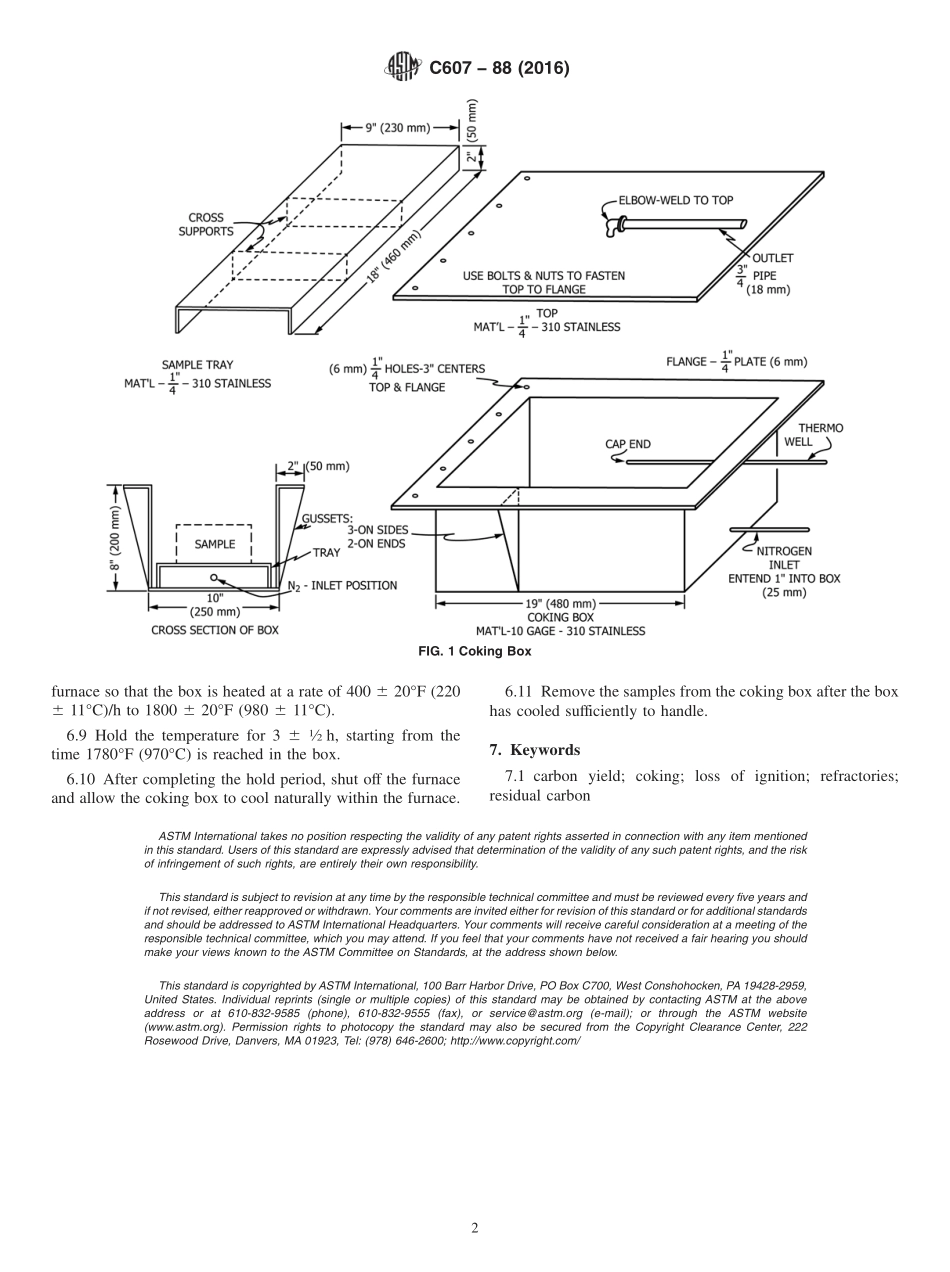

Designation:C607−88(Reapproved2016)StandardPracticeforCokingLargeShapesofCarbon-BearingMaterials1ThisstandardisissuedunderthefixeddesignationC607;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticecoversthepreparationofcokingofcarbon-bearingmaterialforsubsequenttestingsuchasmodu-lusofrupture,slagtesting,thermalconductivity,andthermalexpansion.TestMethodsC831isthespecifiedmethodfortestingresidualcarbon.1.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2C133TestMethodsforColdCrushingStrengthandModu-lusofRuptureofRefractoriesC767TestMethodforThermalConductivityofCarbonRefractoriesC831TestMethodsforResidualCarbon,ApparentResidualCarbon,andApparentCarbonYieldinCokedCarbon-ContainingBrickandShapesC832TestMethodofMeasuringThermalExpansionandCreepofRefractoriesUnderLoadC874TestMethodforRotarySlagTestingofRefractoryMaterials3.SignificanceandUse3.1ThispracticeisusefulforpreparingcokedspecimensforsubsequenttestingwheretheshapesdesiredcannotbefittedintothecokingboxdescribedinTestMethodsC831.3.2Thispracticecanbeverysensitivetoheatingratesincoking.Thus,strictadherencetothecokingprocedureisnecessary.4.Apparatus4.1Furnace,gas-,oil-,orelectric-fired,withheatingcham-bercapableofreceivingthecokingboxshowninFig.1.4.2Box,stainlesssteel,essentiallyasshowninFig.1.5.PreparationofSamples5.1Refertotheappropriatetestmethod(s)orpractice(forexample,TestMethodsC...