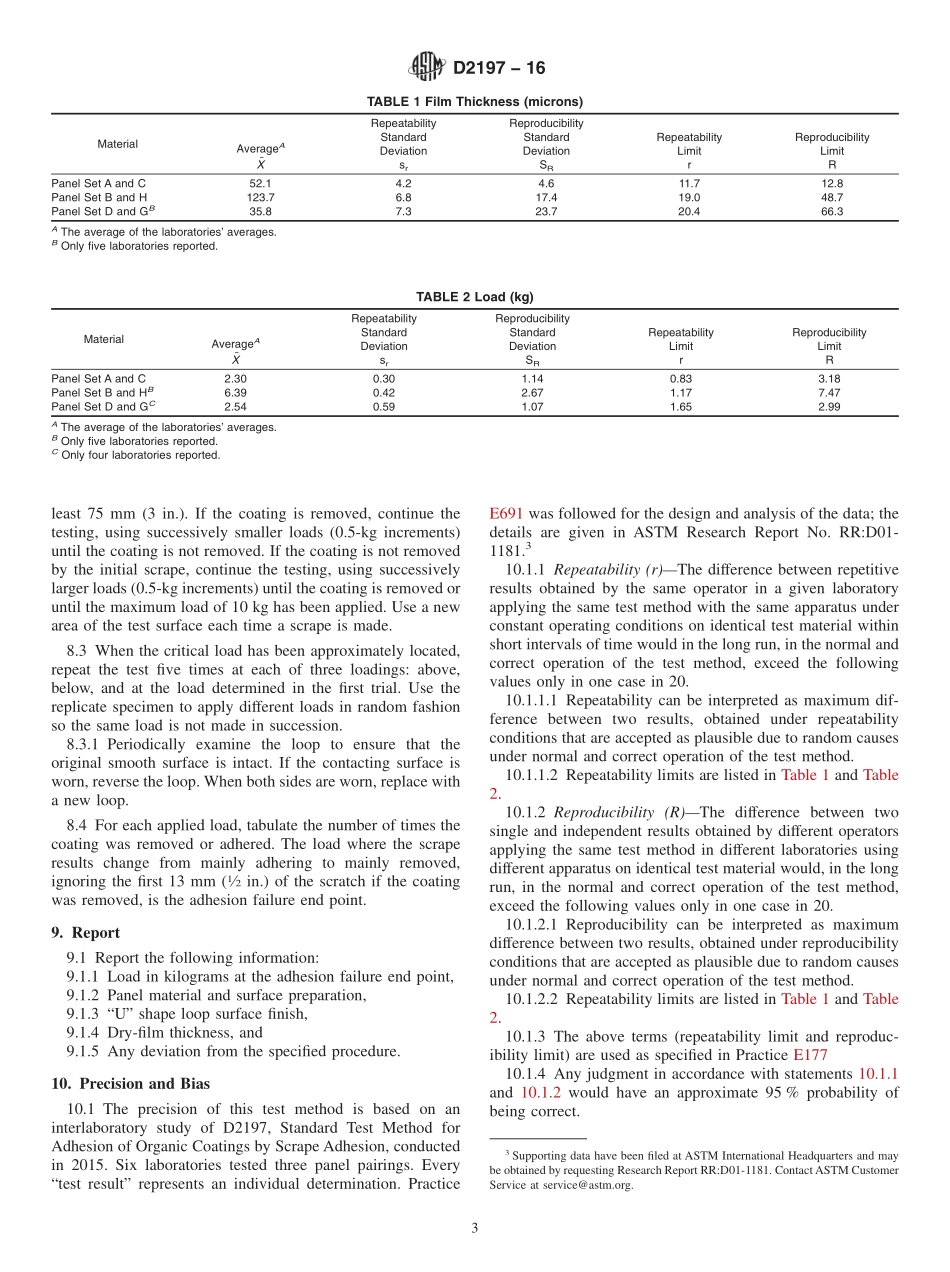

Designation:D2197−16StandardTestMethodforAdhesionofOrganicCoatingsbyScrapeAdhesion1ThisstandardisissuedunderthefixeddesignationD2197;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thistestmethodcoversthedeterminationoftheadhe-sionoforganiccoatingssuchaspaint,varnish,andlacquerwhenappliedtosmooth,flat(planar)panelsurfaces.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D609PracticeforPreparationofCold-RolledSteelPanelsforTestingPaint,Varnish,ConversionCoatings,andRelatedCoatingProductsD823PracticesforProducingFilmsofUniformThicknessofPaint,Varnish,andRelatedProductsonTestPanelsD1005TestMethodforMeasurementofDry-FilmThick-nessofOrganicCoatingsUsingMicrometersD7091PracticeforNondestructiveMeasurementofDryFilmThicknessofNonmagneticCoatingsAppliedtoFerrousMetalsandNonmagnetic,NonconductiveCoat-ingsAppliedtoNon-FerrousMetalsE177PracticeforUseoftheTermsPrecisionandBiasinASTMTestMethodsE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod3.SummaryofTestMethod3.1Thematerialsundertestareappliedatuniformthicknesstoflatpanels,usuallysheetmetalofuniformsurfacetexture.Afterdrying,theadhesionisdeterminedbypushingthepanelsbeneatharoundedstylusorloopthatisloadedinincreasingamountsuntilthecoatingisremovedfromthesubstratesurface.4.SignificanceandUse4.1Coatingstoperformsatisfactorilymustadheretothesubstratesonwhichtheyareapplied.Thist...