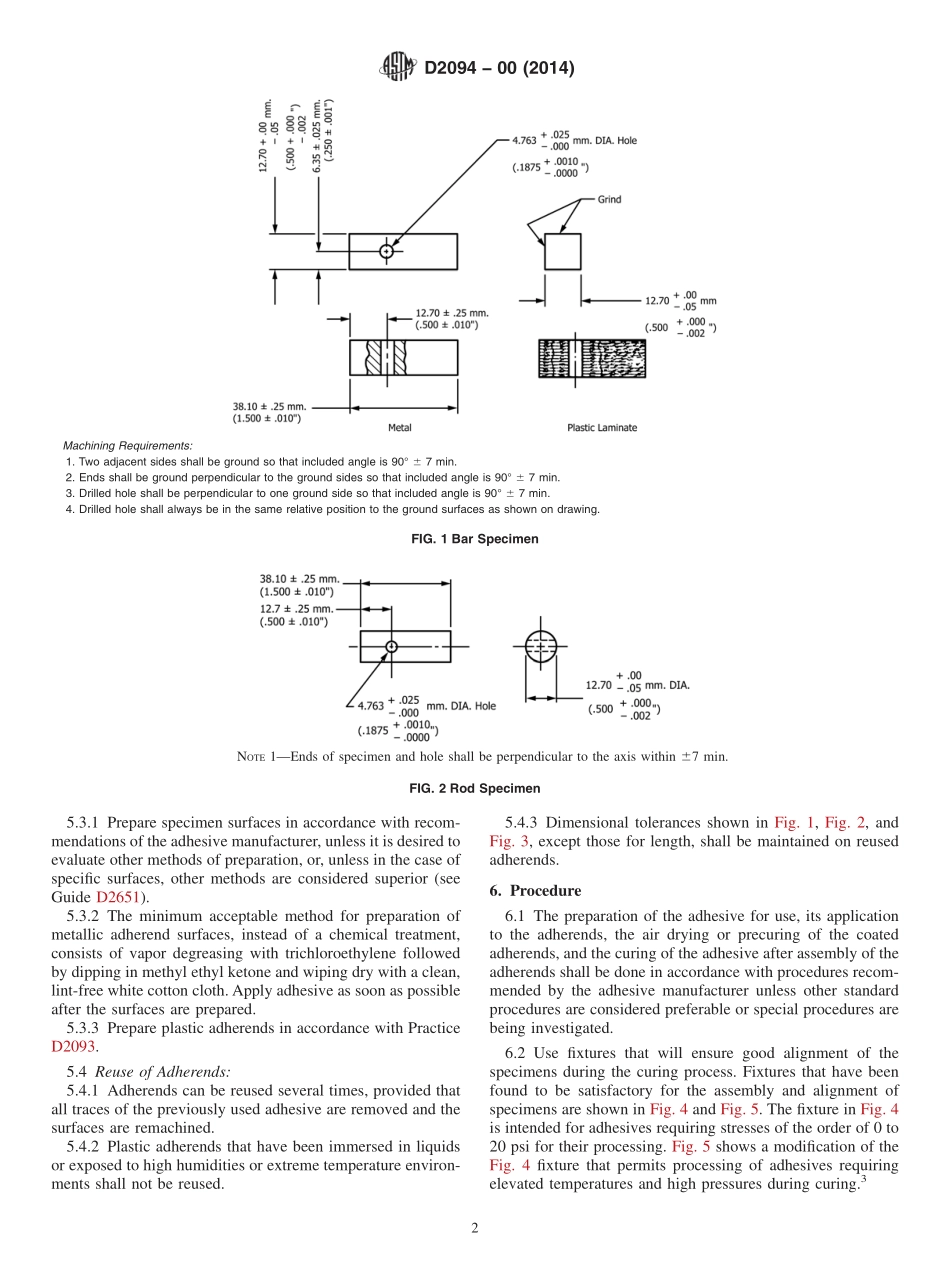

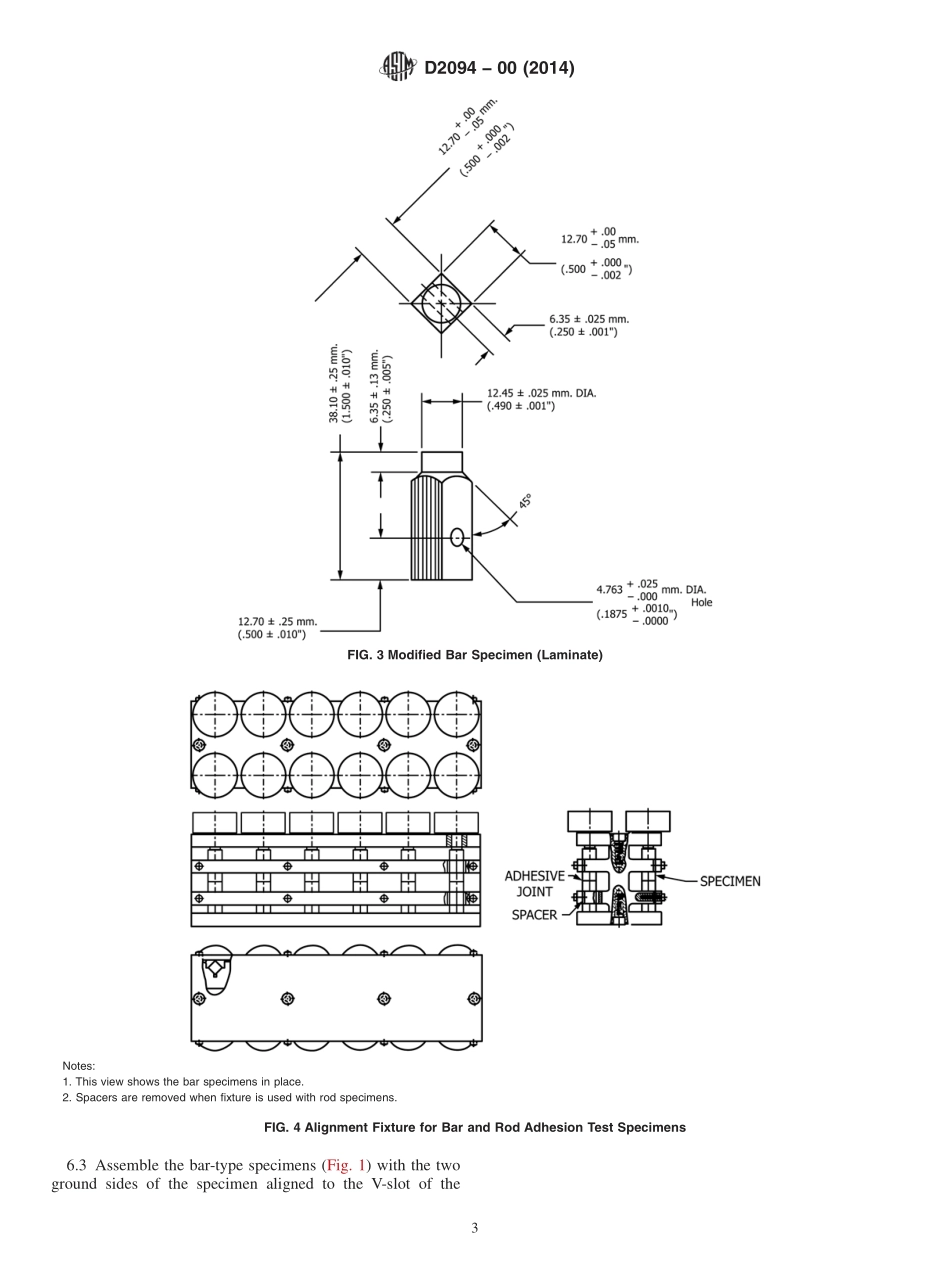

Designation:D2094−00(Reapproved2014)StandardPracticeforPreparationofBarandRodSpecimensforAdhesionTests1ThisstandardisissuedunderthefixeddesignationD2094;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticedescribesbar-androd-typebutt-joinedadhesiontestspecimensandproceduresforpreparingandbondingthem.ThespecimensareintendedtobeusedwithvariousadherendmaterialsinlikeorunlikecombinationsfordeterminingthestrengthpropertiesofadhesivesinaccordancewithTestMethodD2095.1.2ThevaluesstatedinSIunitsareconsideredtobethestandard.Thevaluesinparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D907TerminologyofAdhesivesD2093PracticeforPreparationofSurfacesofPlasticsPriortoAdhesiveBondingD2095TestMethodforTensileStrengthofAdhesivesbyMeansofBarandRodSpecimensD2651GuideforPreparationofMetalSurfacesforAdhesiveBonding2.2ASTMAdjuncts:AlignmentFixtureDrawings33.Terminology3.1Definitions—ManytermsinthispracticearedefinedinTerminologyD907.4.SignificanceandUse4.1Theproceduresoutlinedinthispracticearedesignedtostandardizethetestspecimens,surfacepreparations,combina-tionsofmaterials,andadhesiveselection.Becauseoftheflexibilityintheprocedure,itisimportanttohavesomeideaofthekindofpropertiesthatwillbeobservedduringtesting.5.TestSpecimens5.1Geometry—TestspecimensconformtotheformsanddimensionsshowninFig.1,Fig.2,orFig.3.Onlythebarspecimen(Fig.1)shallbeusedforcleavagestrengthtests.Onlytherodspecimen(Fig.2)orthemodifiedbarspecimen(Fig.3)shallbeusedfortestsintorsionalshear.Amodificationofthespecimenispermissibleintensi...