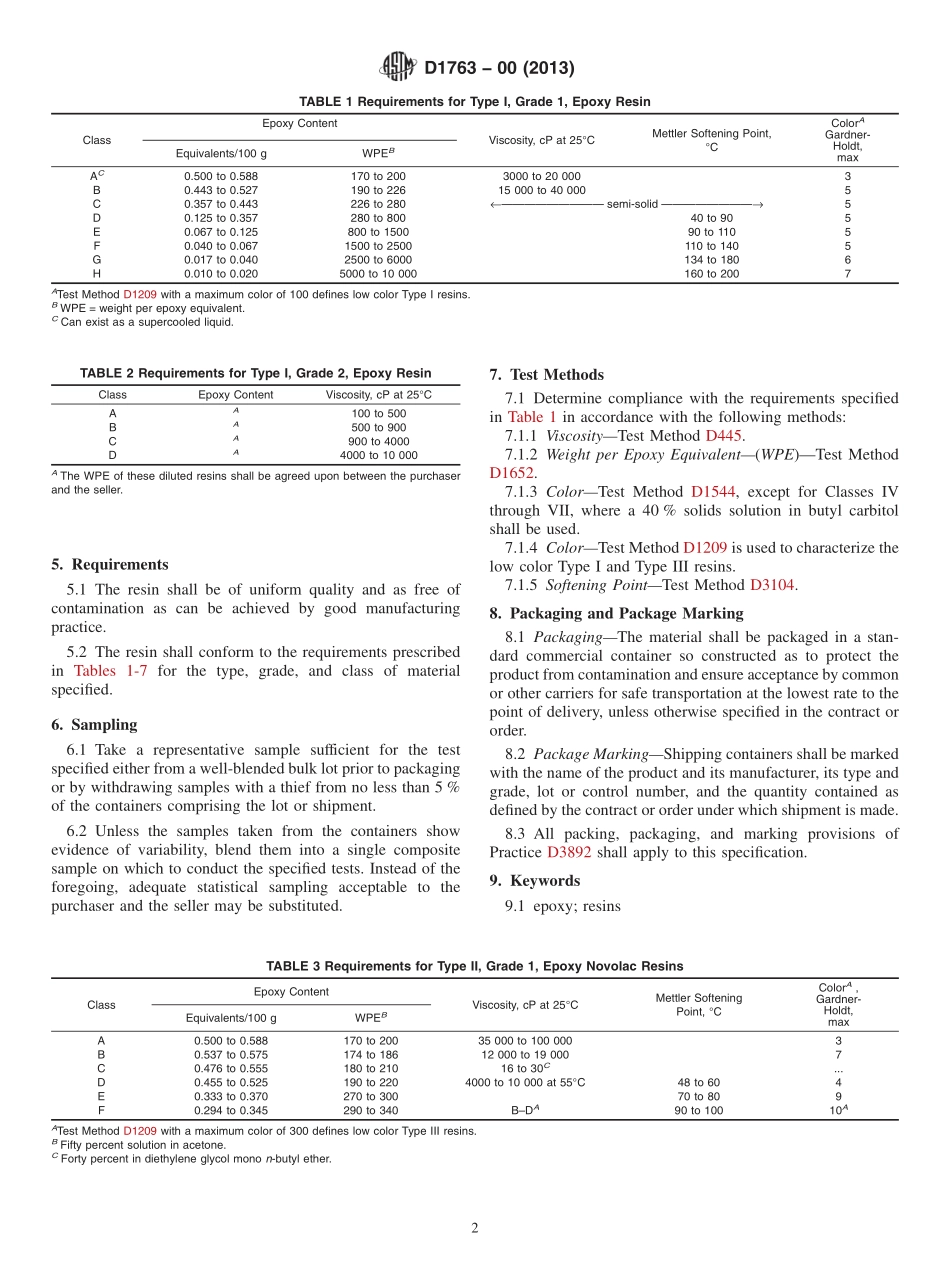

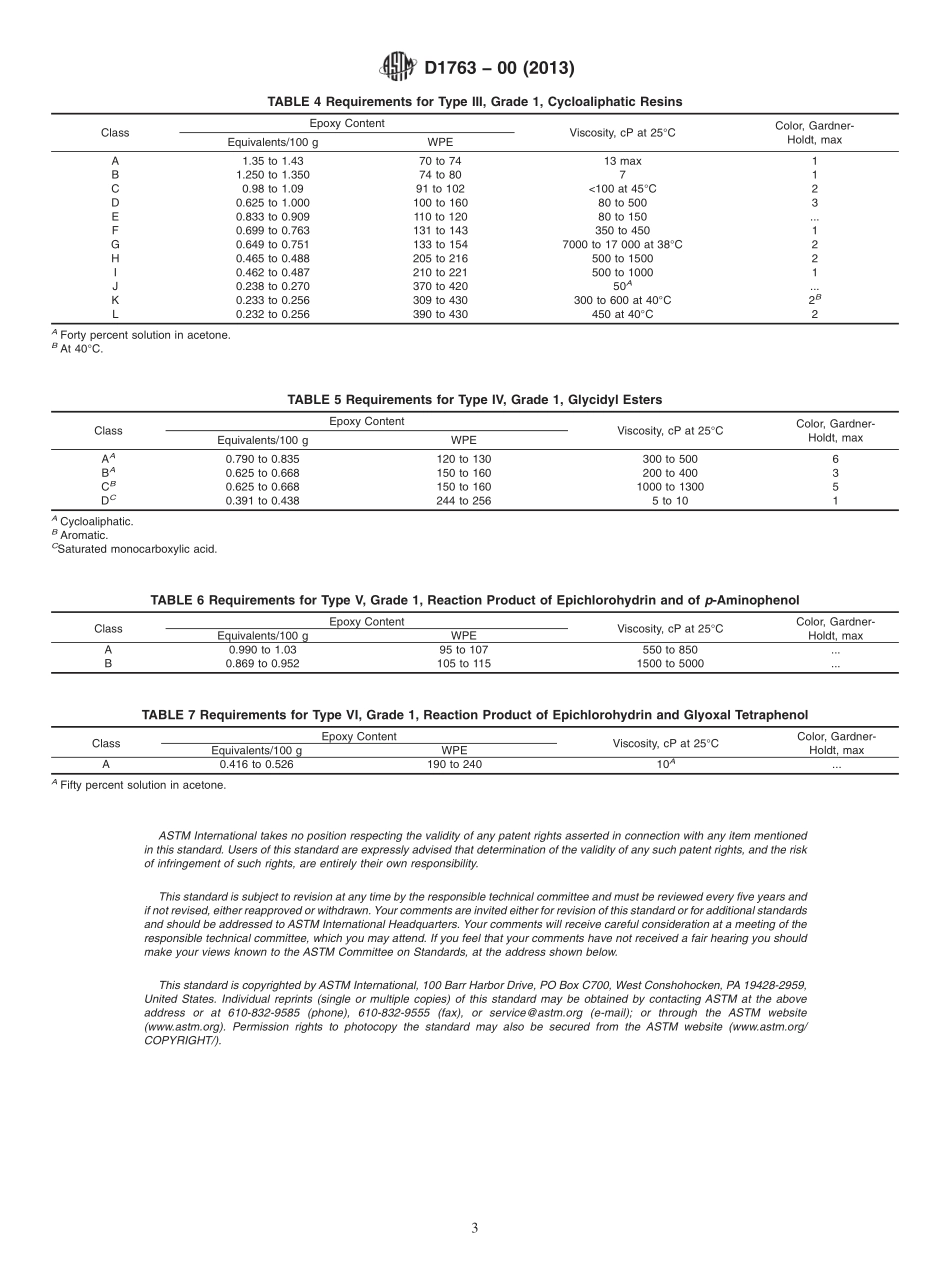

Designation:D1763−00(Reapproved2013)StandardSpecificationforEpoxyResins1ThisstandardisissuedunderthefixeddesignationD1763;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope1.1Thisspecificationcoverstotallyreactiveepoxyresinssuppliedasliquidsorsolidswhichcanbeusedforcastings,coatings,tooling,potting,adhesives,orreinforcedapplica-tions.Theadditionofhardenersintheproperproportionscausestheseresinstopolymerizeintoinfusibleproducts.Thepropertiesoftheseproductscanbemodifiedbytheadditionofvariousfillers,reinforcements,extenders,plasticizers,thixo-tropicagents,etc.Theepoxyresinsdescribedalsocanbeusedasstabilizersandcross-linkingagents;andtheycanbecombinedwithotherreactiveproducts.1.2Itisnotthefunctionofthisspecificationtoprovideengineeringdataortoguidethepurchaserintheselectionofamaterialforaspecificenduse.OrdinarilythepropertieslistedinTable1andTable2aresufficienttocharacterizeamaterialunderthisspecification,anditisrecommendedthatroutineinspectionbelimitedtotestingforsuchproperties.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.1.4ThevaluesstatedinSIunitsaretoberegardedasstandard.NOTE1—ISO3673–1:1980(E)issimilarbutnotequivalenttothisspecification.Productclassificationandcharacterizationarenotthesame.2.ReferencedDocuments2.1ASTMStandards:2D445TestMethodforKinematicViscosityofTransparentandOpaqueLiquids(andCalculationofDynamicViscos-ity)D883TerminologyRelatingtoPlasticsD1209TestMethodforColorofClearLiquids(Platinum-CobaltScale)D1544TestMethodforColorofTransparentLiquids(Gard-nerColorScale)D1652TestMet...