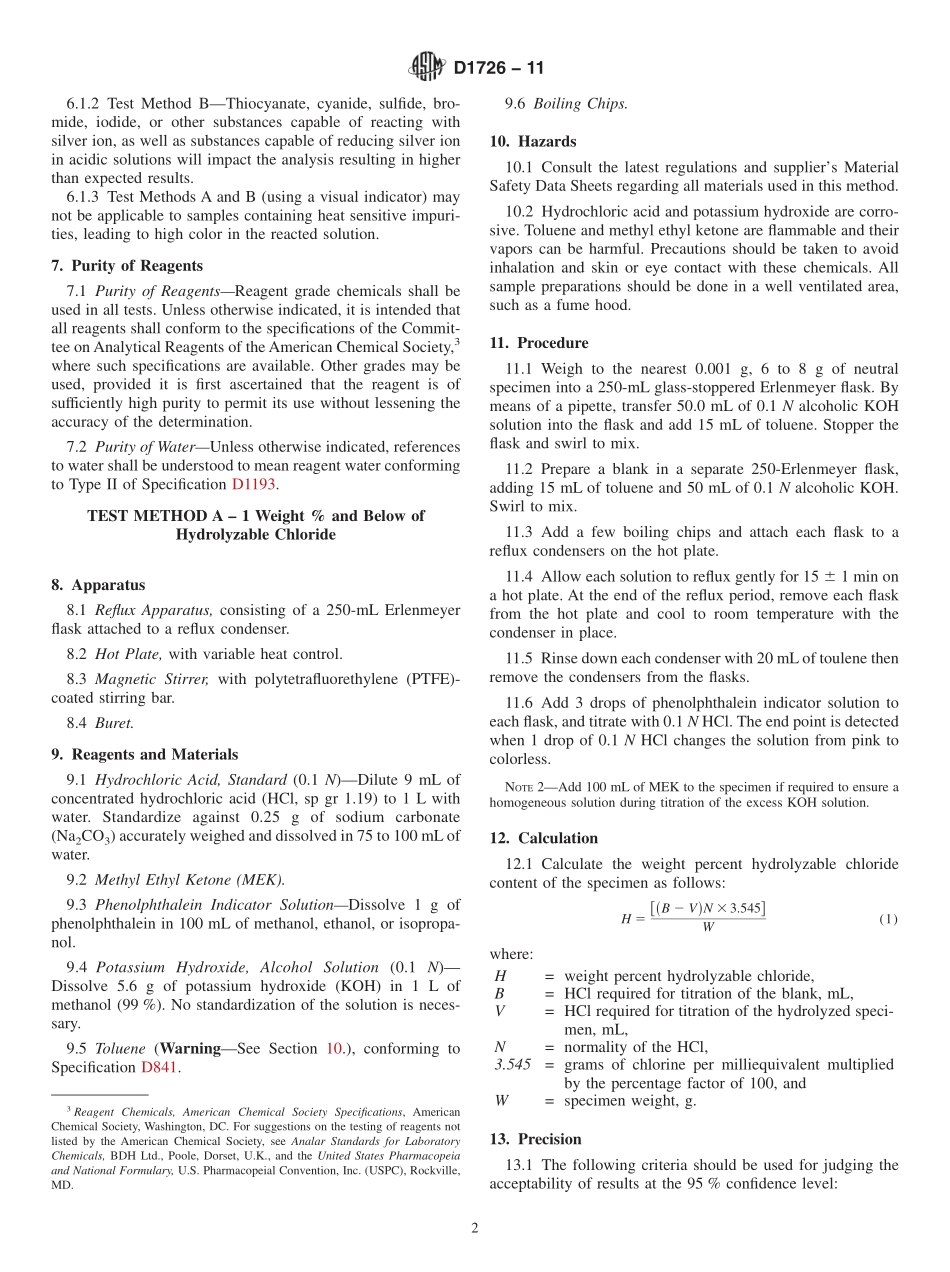

Designation:D1726−11StandardTestMethodsforHydrolyzableChlorideContentofLiquidEpoxyResins1ThisstandardisissuedunderthefixeddesignationD1726;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope1.1Thesetestmethodscoverthedeterminationoftheeasilyhydrolyzablechloridecontentofliquidepoxyresinswhicharedefinedasthereactionproductofachlorohydrinandadi-orpolyfunctionalphenoliccompound.NOTE1—ThereisnoknownISOequivalenttothisstandard.1.1.1InTestMethodA,theeasilyhydrolyzablechlorideissaponifiedwithpotassiumhydroxideanddirectlytitratedwithhydrochloricacid.Thistestmethodcanbeusedforconcen-trationsof1weight%andbelow.1.1.2InTestMethodB,theeasilyhydrolyzablechlorideisagainsaponifiedwithpotassiumhydroxide,thentitratedpo-tentiometricallywithsilvernitrate.Thistestmethodcanbeusedforconcentrationsof5to2500ppmhydrolyzablechloride.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.ForspecifichazardstatementsseeSections10and16.2.ReferencedDocuments2.1ASTMStandards:2D329SpecificationforAcetoneD841SpecificationforNitrationGradeTolueneD1193SpecificationforReagentWaterD3620SpecificationforGlacialAceticAcidD6440TerminologyRelatingtoHydrocarbonResinsE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod3.Terminology3.1TheterminologyinthesetestmethodsfollowsthestandardterminologydefinedinTerminologyD6440.3.2Definitions:3.3hydrolyzablechloride,n—thelowlevelchlorine-containingcomponentsoftheliquidepox...