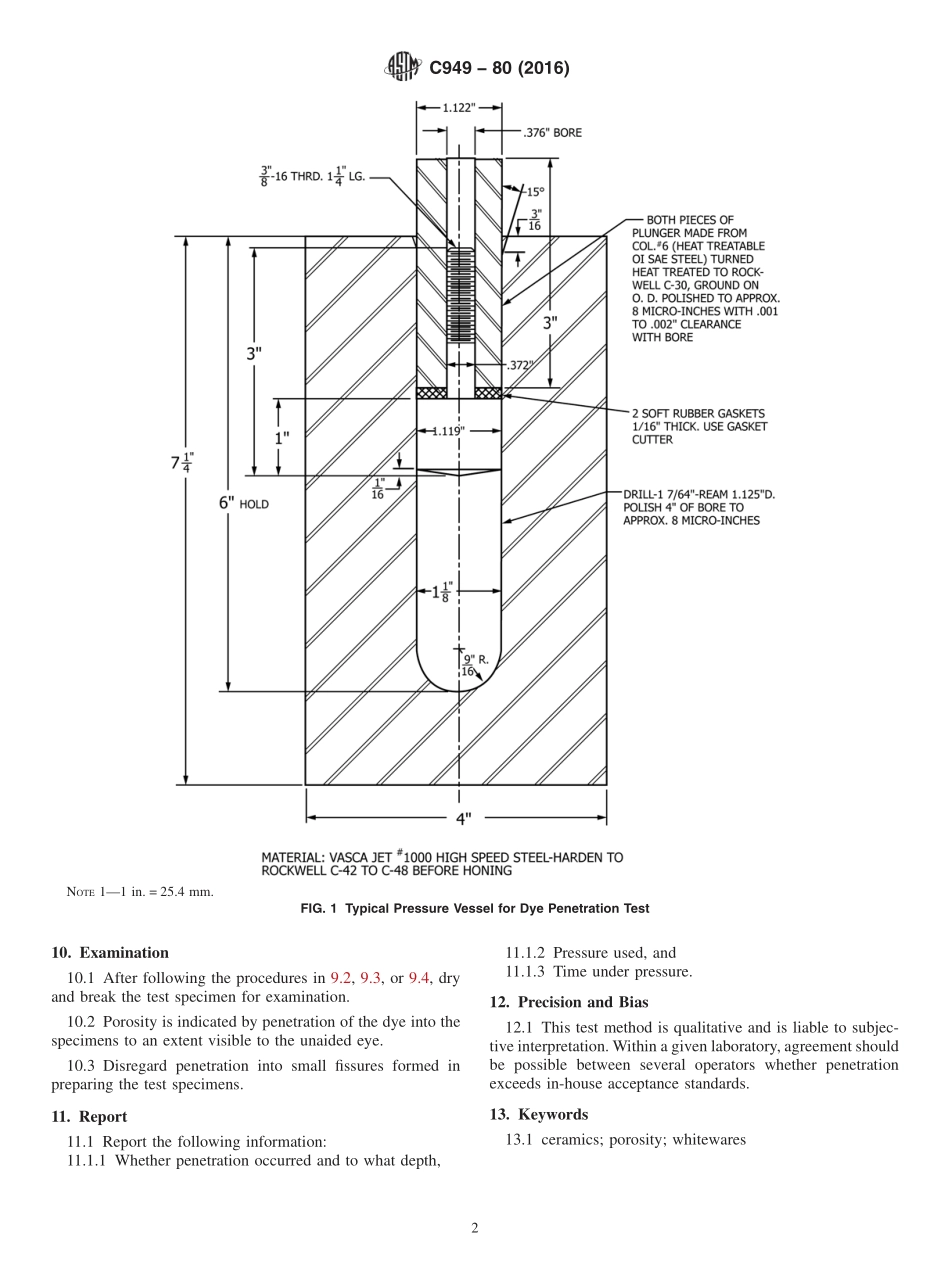

Designation:C949−80(Reapproved2016)StandardTestMethodforPorosityinVitreousWhitewaresbyDyePenetration1ThisstandardisissuedunderthefixeddesignationC949;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversproceduresfordetectingpores,cracks,orothervoidsthatmaybepresentinotherwiseimpermeablewhitewareceramics,orasporosityinunderfiredware.NOTE1—ThistestmethodwaspartiallyderivedfromANSIC29.1.1.2Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse2.ReferencedDocuments2.1ASTMStandards:2C242TerminologyofCeramicWhitewaresandRelatedProducts2.2ANSIStandard:C29.1TestMethodsforElectricalPowerInsulators33.Terminology3.1Definitions:3.1.1Fordefinitionsoftermsusedinthistestmethod,refertoTerminologyC242.4.SummaryofTestMethod4.1Randomlyselectedunglazedfragmentsofvitreouswhitewareproductsareimmersedinafuchsinedyesolution,atoneormorepressuresforprescribedtimes.Afterdrying,thespecimensarebrokenandinspectedfortheextentofdyepenetrationintothebody,orintodefectspresentinthebody.5.SignificanceandUse5.1Thistestmethodprovidesameansforreadilydetermin-ingifaceramicisproperlyfired(matured).Penetrationofanyextentmaynegatetheusefulnessoftheceramic,or,arbitrarily,somedegreeofpenetrationmaybeacceptablefortheuseorcommercialqualityoftheitembeingtested.6.Apparatus6.1Vessel,capableofapplyingandholdingapressureof10000psi(68.9MPa).6.1.1Fig.1illustratesasatisfactorydevice.NOTE2—Fig.1doesnotrepresenttheonlypossibledesignorconfiguration.Itisrepresentativeofadevicethathasbeensuccessfullyused.6.1.2Fig.2illustratesanactualdeviceandtypicalex-amples.6.1.3Fig.3illustratesanassembleddevice,includingfi...