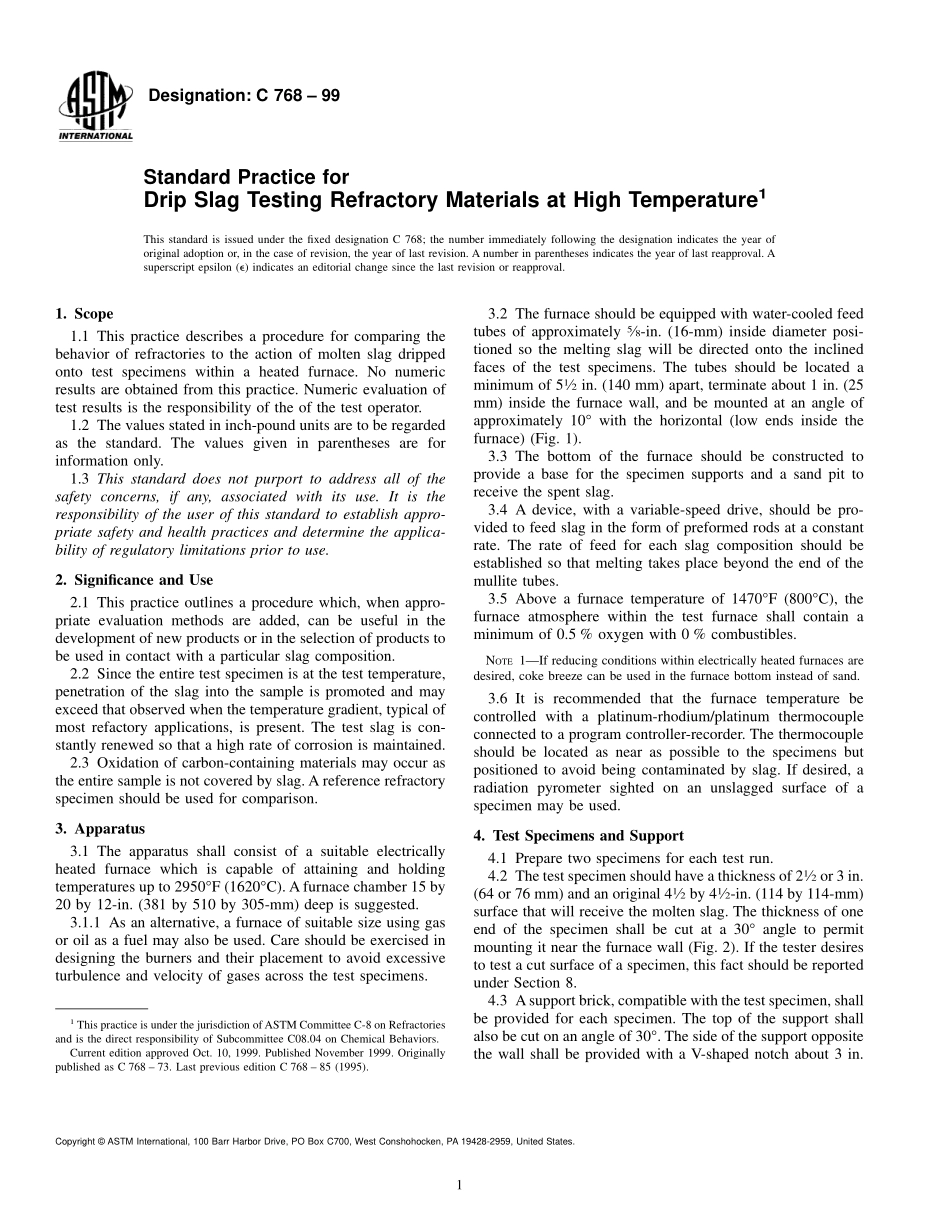

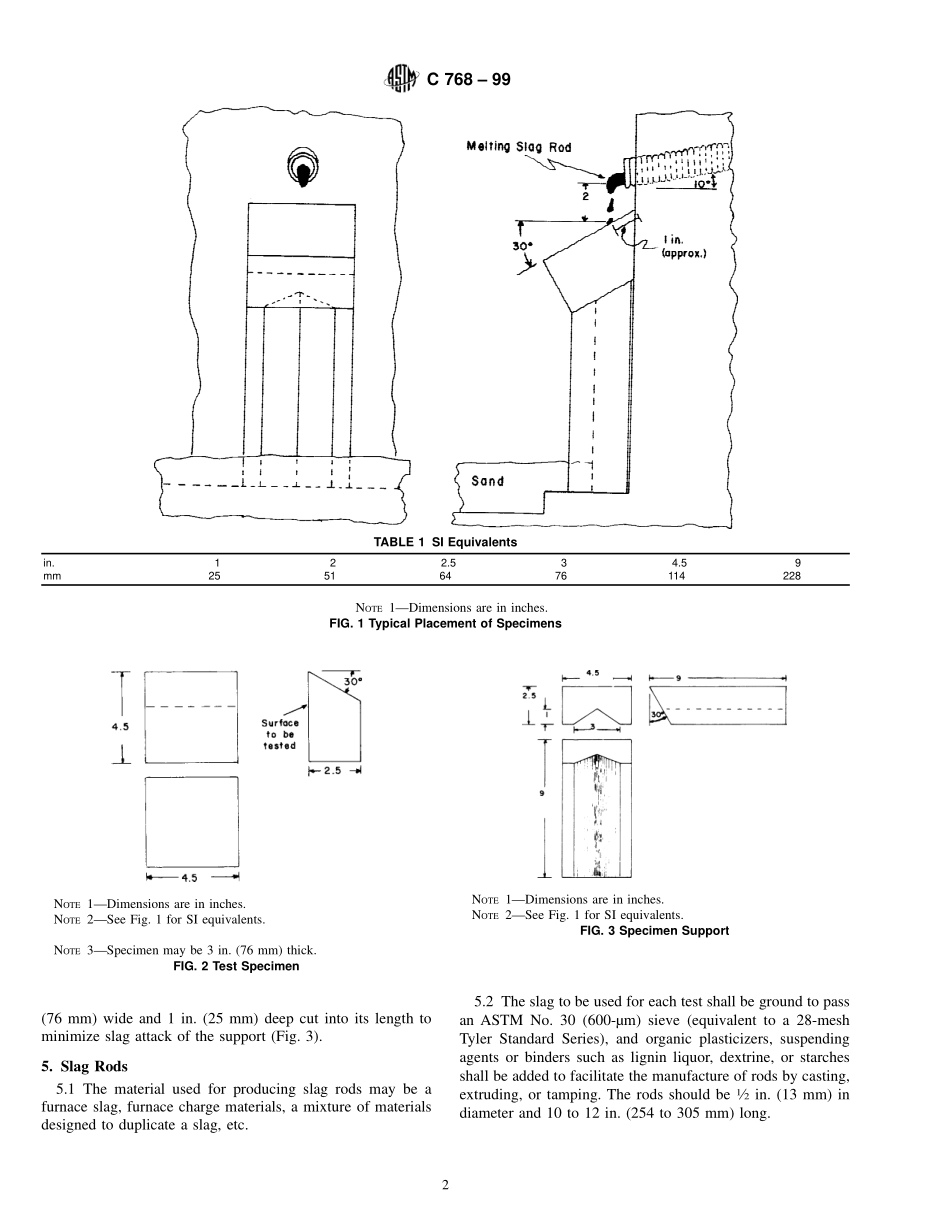

Designation:C768–99StandardPracticeforDripSlagTestingRefractoryMaterialsatHighTemperature1ThisstandardisissuedunderthefixeddesignationC768;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticedescribesaprocedureforcomparingthebehaviorofrefractoriestotheactionofmoltenslagdrippedontotestspecimenswithinaheatedfurnace.Nonumericresultsareobtainedfromthispractice.Numericevaluationoftestresultsistheresponsibilityoftheofthetestoperator.1.2Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.SignificanceandUse2.1Thispracticeoutlinesaprocedurewhich,whenappro-priateevaluationmethodsareadded,canbeusefulinthedevelopmentofnewproductsorintheselectionofproductstobeusedincontactwithaparticularslagcomposition.2.2Sincetheentiretestspecimenisatthetesttemperature,penetrationoftheslagintothesampleispromotedandmayexceedthatobservedwhenthetemperaturegradient,typicalofmostrefactoryapplications,ispresent.Thetestslagiscon-stantlyrenewedsothatahighrateofcorrosionismaintained.2.3Oxidationofcarbon-containingmaterialsmayoccurastheentiresampleisnotcoveredbyslag.Areferencerefractoryspecimenshouldbeusedforcomparison.3.Apparatus3.1Theapparatusshallconsistofasuitableelectricallyheatedfurnacewhichiscapableofattainingandholdingtemperaturesupto2950°F(1620°C).Afurnacechamber15by20by12-in.(381by510by305-mm)deepissuggested.3.1.1Asanalternative,afurnaceofsuitablesizeusinggasoroilasafuelmayalsobeused.Careshouldbeexercisedindesigningtheburnersandtheirplacementtoavoidexcessiveturbulenceand...