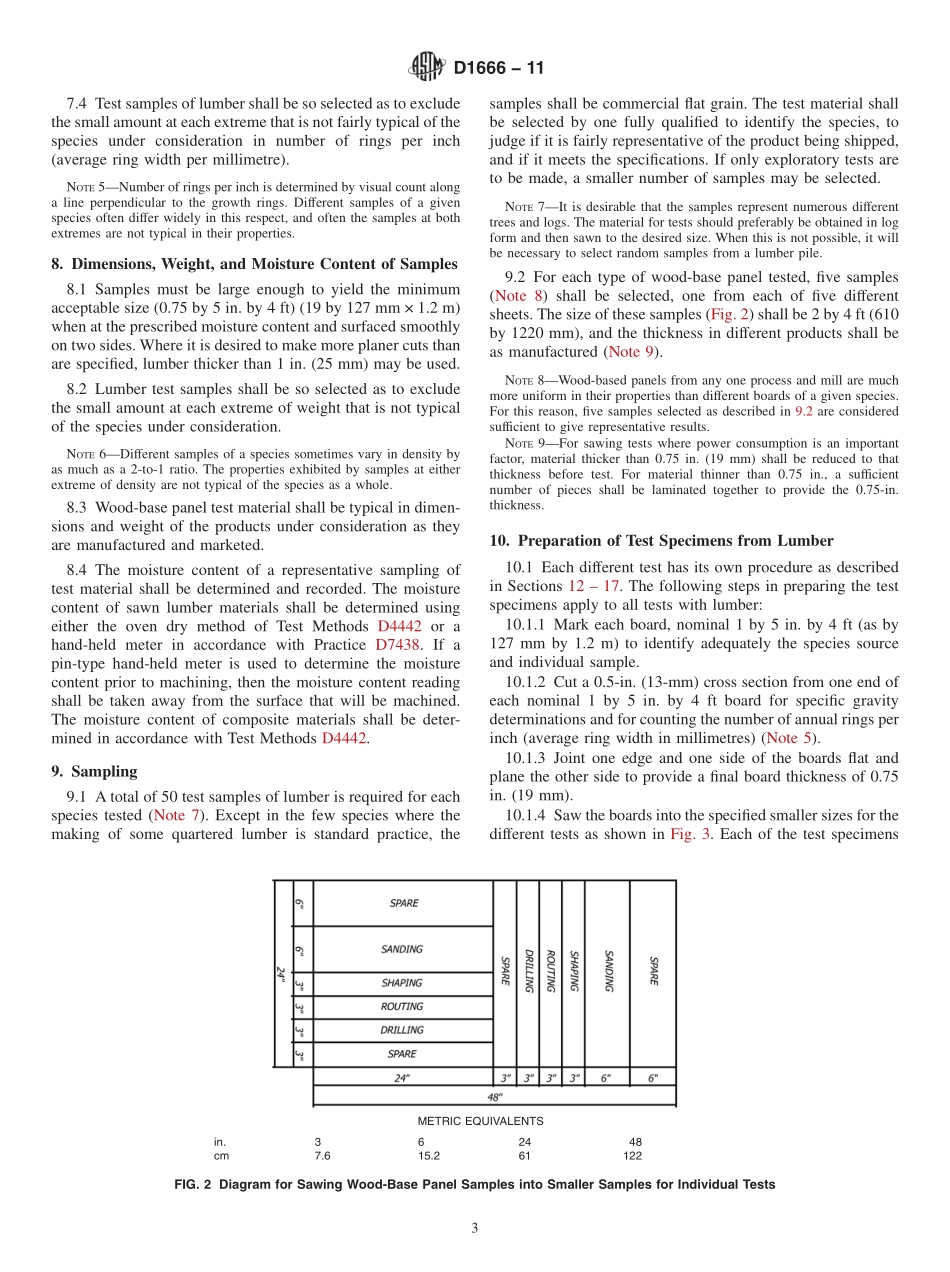

Designation:D1666−11StandardTestMethodsforConductingMachiningTestsofWoodandWood-BasePanelMaterials1ThisstandardisissuedunderthefixeddesignationD1666;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.INTRODUCTIONOneofthesignificantcharacteristicsofwoodandwood-basepanelsisthefacilitywithwhichtheycanbemachinedandfabricated.Differentspeciesandproducts,however,varygreatlyintheirbehaviorundercuttingtools,sothatsomesystematicmethodisneededfordeterminingtheirsuitabilityforuseswherethecharacterofthemachinedsurfaceisofprimeimportance.Suchusesincludecabinetwork,millwork,andotherapplicationswherefavorablemachiningpropertiesareessentialtogoodfinish.Forsuchproductsascommonboards,ontheotherhand,goodmachiningpropertiesaresecondary,althoughstillanasset.Themachiningtestprocedurespresentedinthesetestmethodscoversuchcommonoperationsasplaning,routing/shaping,turning,boring,mortising,andsanding.Theyaretheresultofmanyyearsofextensiveresearchanddevelopmentandincludepracticalmethodsforqualitativelyevaluatingandinterpretingtheresults.Becauseoftheirsatisfactoryusewithawiderangeofmaterials,itisbelievedthatthemethodsareequallyapplicabletospecies,hardwoodsandsoftwoods,andtowood-basepanelmaterials,suchasplywood,particleboard,fiberboard,andhardboard.1.Scope1.1Thesetestmethodscoverproceduresforplaning,routing/shaping,turning,mortising,boring,andsanding,allofwhicharecommonwood-workingoperationsusedinthemanufactureofwoodproducts.Thesetestsapply,indifferentdegrees,totwogeneralclassesofmaterials:1.1.1Woodintheformoflumber,and1.1.2Wood-basepanelmaterialssuchasplywoodandwood-basefiberandparticlepanels.1.2Becauseoftheimportanceofplaning,someofthevariablesthataffecttheresultsofthisoperationareexploredwithaviewtodeterminingoptimumconditions.Inmostoftheothertests,however,itisnecessarytolimittheworktoo...