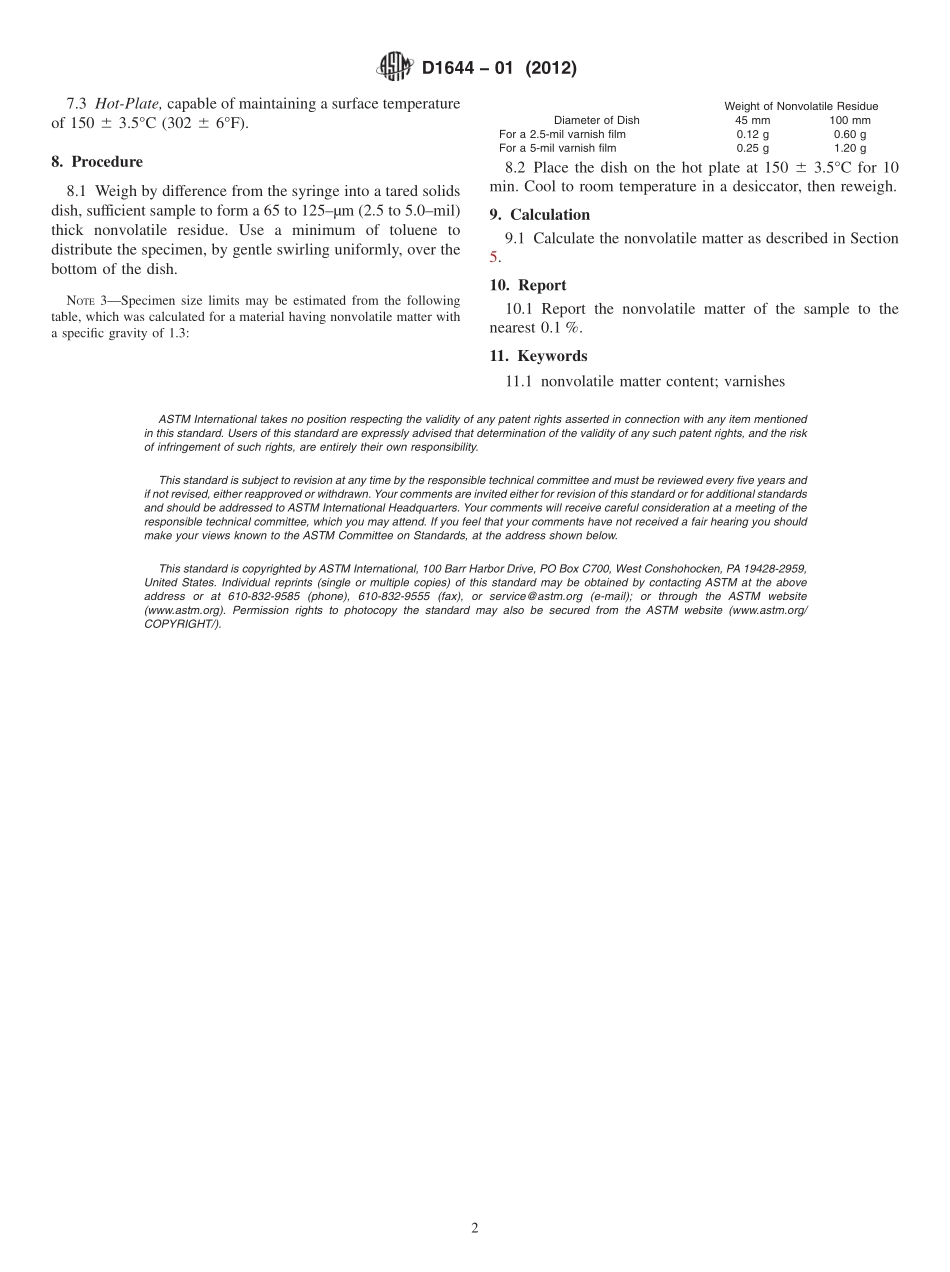

Designation:D1644−01(Reapproved2012)StandardTestMethodsforNonvolatileContentofVarnishes1ThisstandardisissuedunderthefixeddesignationD1644;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope1.1Thesetestmethodsdeterminethefractionofavarnishthatisnonvolatileatthetemperatureofthetestwhilevolatilesolventsaredrivenoff.Itissometimesanapproximatemeasureofthefilm-formingmatterinavarnish.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.Foraspecificstatement,seeSection3.2.SignificanceandUse2.1Thesetestmethodsareapplicabletovarnishandareusefultoproducersandusersindeterminingnonvolatilecontentandaresometimesanappropriatemeasureofthefilm-formingmatterinvarnish.3.Hazards3.1Sincetheflashpointsofsomeofthesolventsusedincoatingsandrelatedproductsarebelowthetemperatureofthetest,careshouldbeexercisedthatthelowerexplosivelimitsofthesolventsarenotexceeded.Theamountofsolventintheovenatmosphereatanyonetimewilldependonthenumberoftests(pans)intheoven,thepercentnonvolatileofthesamples,thesizeoftheoven,thetypeofoven(mechanicalorgravityconvection)andtheairchangesperhour.TESTMETHODA—3hAT105°C4.Procedure4.1Placeaportionofthethoroughlymixedsampleinastopperedbottle,oralternatively,inaweighingpipetora10-mLsyringewithoutaneedle,andfromthisweighbydifference1.260.1gintoataredflat-bottomedmetalorglassdish(Note1),80to100mmindiameterand5to10mmindepth,suchasfriction-topcancovers,ointmentboxes,orpetridishes.NOTE1—Theterm“tared,flat-...