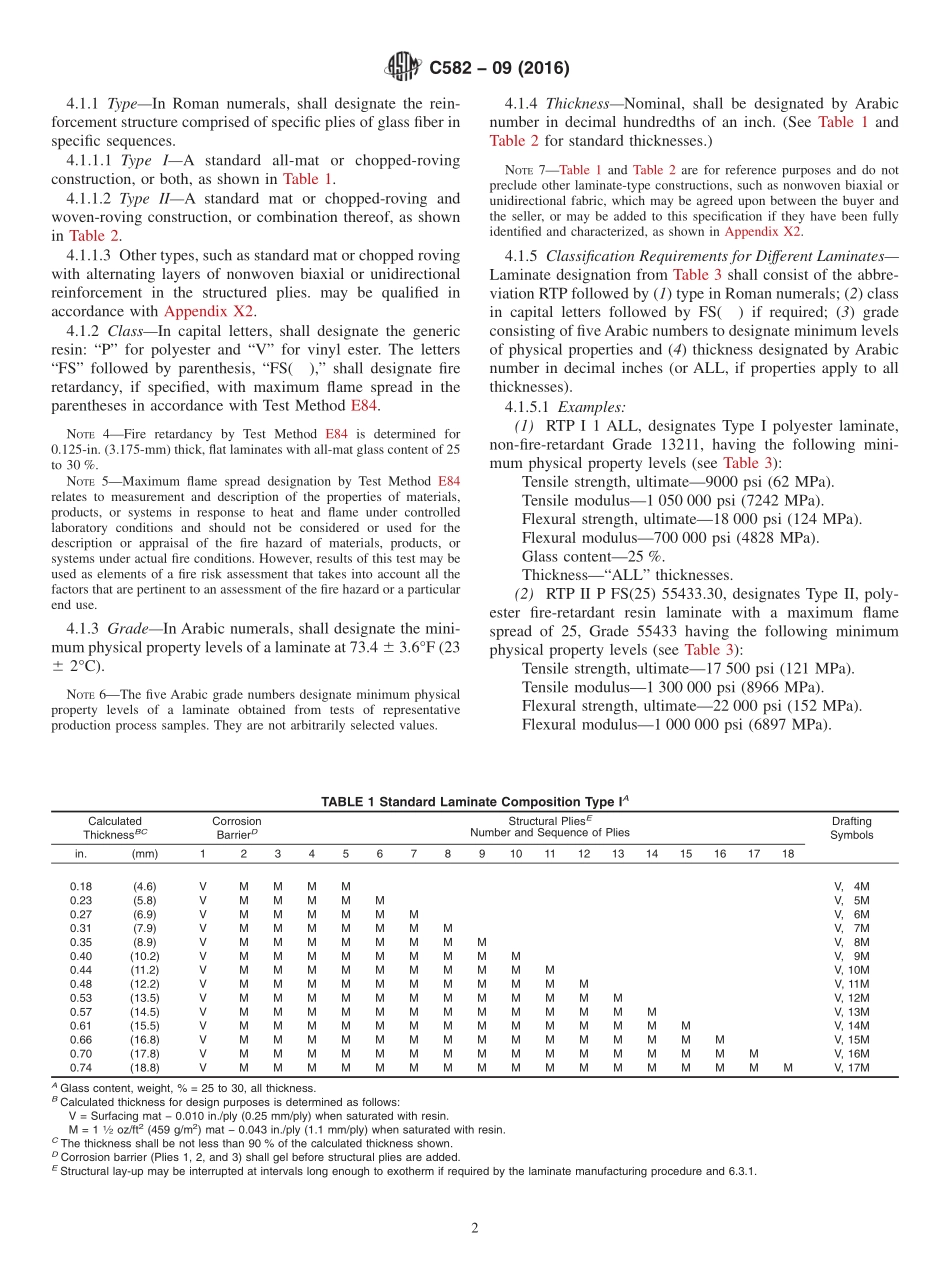

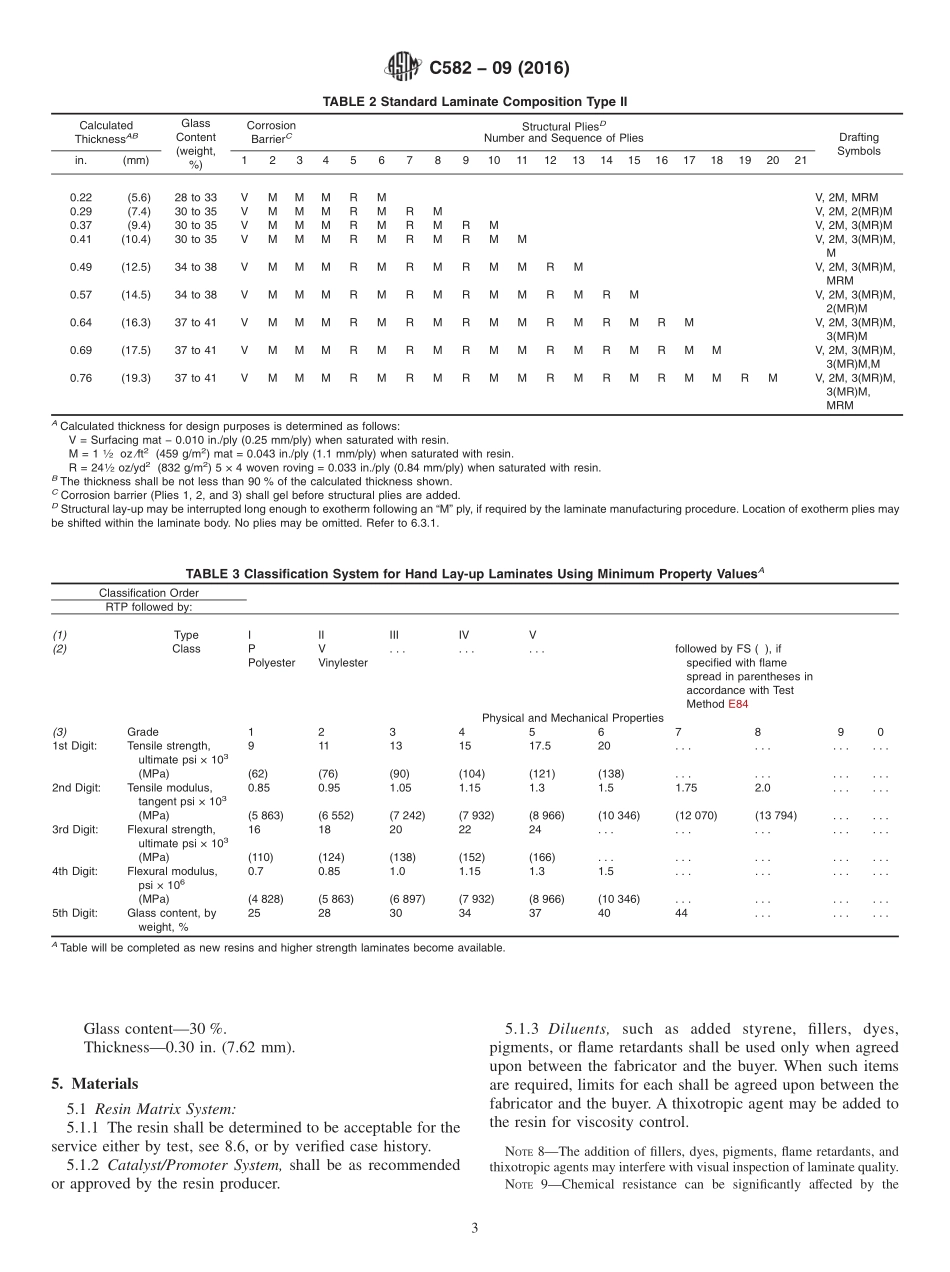

Designation:C582−09(Reapproved2016)AnAmericanNationalStandardStandardSpecificationforContact-MoldedReinforcedThermosettingPlastic(RTP)LaminatesforCorrosion-ResistantEquipment1ThisstandardisissuedunderthefixeddesignationC582;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thisspecificationcoverscomposition,thickness,fabri-catingprocedures,andphysicalpropertyrequirementsforglassfiberreinforcedthermosetpolyester,vinylester,orotherqualifiedthermosettingresinlaminatescomprisingthemateri-alsofconstructionforRTPcorrosion-resistanttanks,piping,andequipment.Thisspecificationislimitedtofabricationbycontactmolding.NOTE1—Thelaminatescoveredbythisspecificationaremanufacturedduringfabricationofcontact-moldedRTPtanks,piping,andotherequipment.NOTE2—ThereisnoknownISOequivalenttothisstandard.1.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.3Thefollowingsafetyhazardscaveatpertainsonlytothetestmethodportion,Section8,ofthisspecification:Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimita-tionspriortouse.2.ReferencedDocuments2.1ASTMStandards:2C581PracticeforDeterminingChemicalResistanceofThermosettingResinsUsedinGlass-Fiber-ReinforcedStructuresIntendedforLiquidServiceD638TestMethodforTensilePropertiesofPlasticsD695TestMethodforCompressivePropertiesofRigidPlasticsD790TestMethodsforFlexuralPropertiesofUnreinforcedandReinforcedPlasticsandElectricalInsulatingMateri-alsD883TerminologyRelatingtoPlasti...