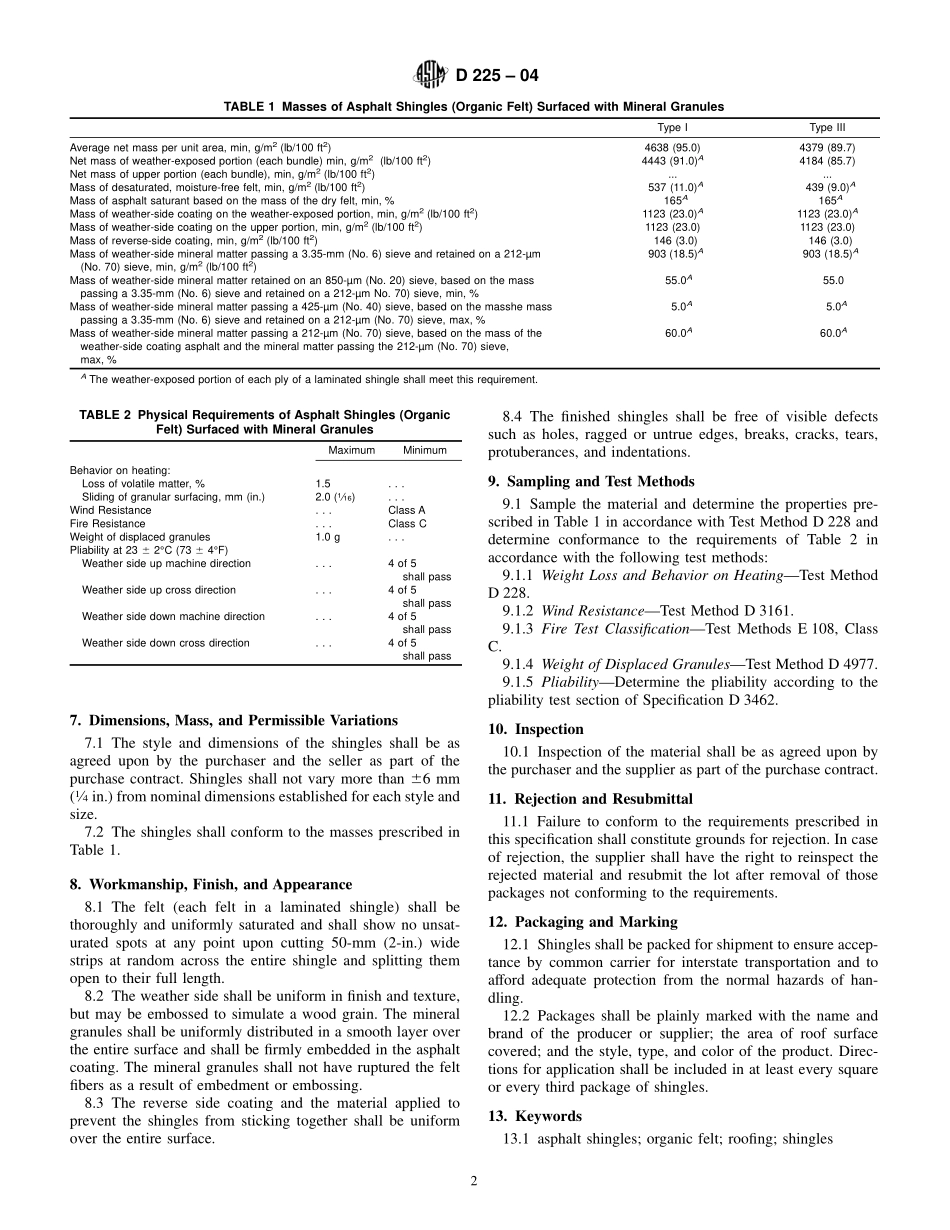

Designation:D225–04StandardSpecificationforAsphaltShingles(OrganicFelt)SurfacedWithMineralGranules1ThisstandardisissuedunderthefixeddesignationD225;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope1.1Thisspecificationcoversasphaltroofinginshingleform,composedofsingleormultiplethicknessesoforganicfeltsaturatedandcoatedonbothsideswithasphaltandsurfacedontheweathersidewithmineralgranules.1.2Shinglesmeetingthisspecificationareintendedtobeappliedwithaheadlapofnotlessthan51mm(2in.).1.3ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.2.ReferencedDocuments2.1ASTMStandards:2D228TestMethodforSampling,Testing,andAnalysisofAsphaltRollRoofing,CapSheets,andShinglesUsedinRoofingandWaterproofingD1079TerminologyRelatingtoRoofing,Waterproofing,andBituminousMaterialsD3161TestMethodforWind-ResistanceofAsphaltShingles(Fan-InducedMethod)D3462SpecificationforAsphaltShinglesMadefromGlassFeltandSurfacedwithMineralGranulesD4977TestMethodforGranuleAdhesiontoMineralSurfacedRoofingbyAbrasionE108TestMethodsforFireTestsofRoofCoverings3.Terminology3.1Definitions—Fordefinitionsofterms,seeTerminologyD1079.3.2DefinitionsofTermsSpecifictoThisStandard:3.2.1weather-exposedportion—anyportionofashingleexposedtotheweatherwhenappliedinaccordancewiththemanufacturer’sinstructions,excludinganypartoftheupperportionexposedbyacutout.4.Classification4.1TypeI—Uniformornonuniformthicknessshinglesofanystyle(seeTable1).4.2TypeIII—Uniformornonuniformthicknessshinglesofanystyle(seeTable1).5.MaterialsandManufacture5.1Intheprocessofmanufacture,asinglethicknessofdryfeltshallbeimpregnatedwithahotasphalticsaturant,thencoatedonbothsideswithahotasphalticcoating,andfinallysurfacedontheweath...