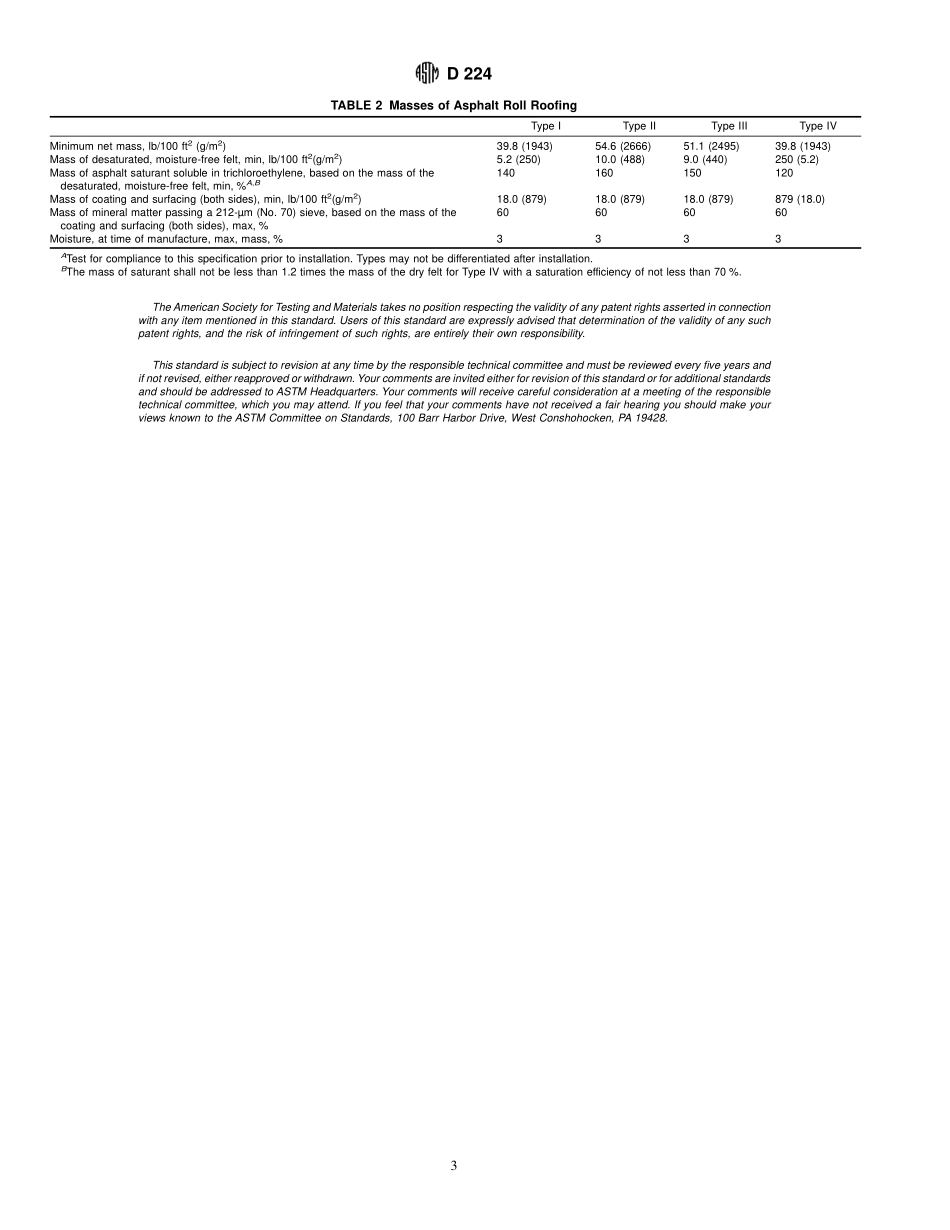

Designation:D224–89(Reapproved1996)StandardSpecificationforSmooth-SurfacedAsphaltRollRoofing(OrganicFelt)1ThisstandardisissuedunderthefixeddesignationD224;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope1.1Thisspecificationcoversasphaltroofinginsheetform,composedoforganicroofingfelt,saturatedwithasphaltandcoatedonbothsideswithanasphalticcompoundwhichmayormaynotcontainmineralstabilizer,andsurfacedwithpowderedtalc,mica,orotherfinemineralmattertopreventsticking.1.2Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:D146TestMethodsforSamplingandTestingBitumen-SaturatedFeltsandWovenFabricsforRoofingandWa-terproofing2D228TestMethodsforAsphaltRollRoofing,CapSheets,andShingles2D1079TerminologyRelatingtoRoofing,Waterproofing,andBituminousMaterials2E96TestMethodsforWaterVaporTransmissionofMate-rials33.Terminology3.1Definitions—Fordefinitionsoftermsusedinthisspeci-fication,refertoTerminologyD1079.4.Classification4.1TypeI—Minimumnetmassperunitareaofroofing,39.8lb/100ft2(1943g/m2).4.2TypeII—Minimumnetmassperunitareaofroofing,54.6lb/100ft2(2666g/m2).4.3TypeIII—Minimumnetmassperunitareaofroofing,51.1lb/100ft2(2495g/m2).4.4TypeIV—Minimumnetmassperunitareaofroofing,39.8lb/100ft2(1943g/m2).5.MaterialsandManufacture5.1Intheprocessofmanufacture,asinglethicknessofdryorganicfeltshallbeimpregnatedwithanasphalticsaturant,thencoatedonbothsideswithasphalticcoatingwhichmaybecompoundedwithafinemineralstabilizersubstantiallyin-solubleinwater,andfinallysurfacedononesidewithfinemineralmatt...