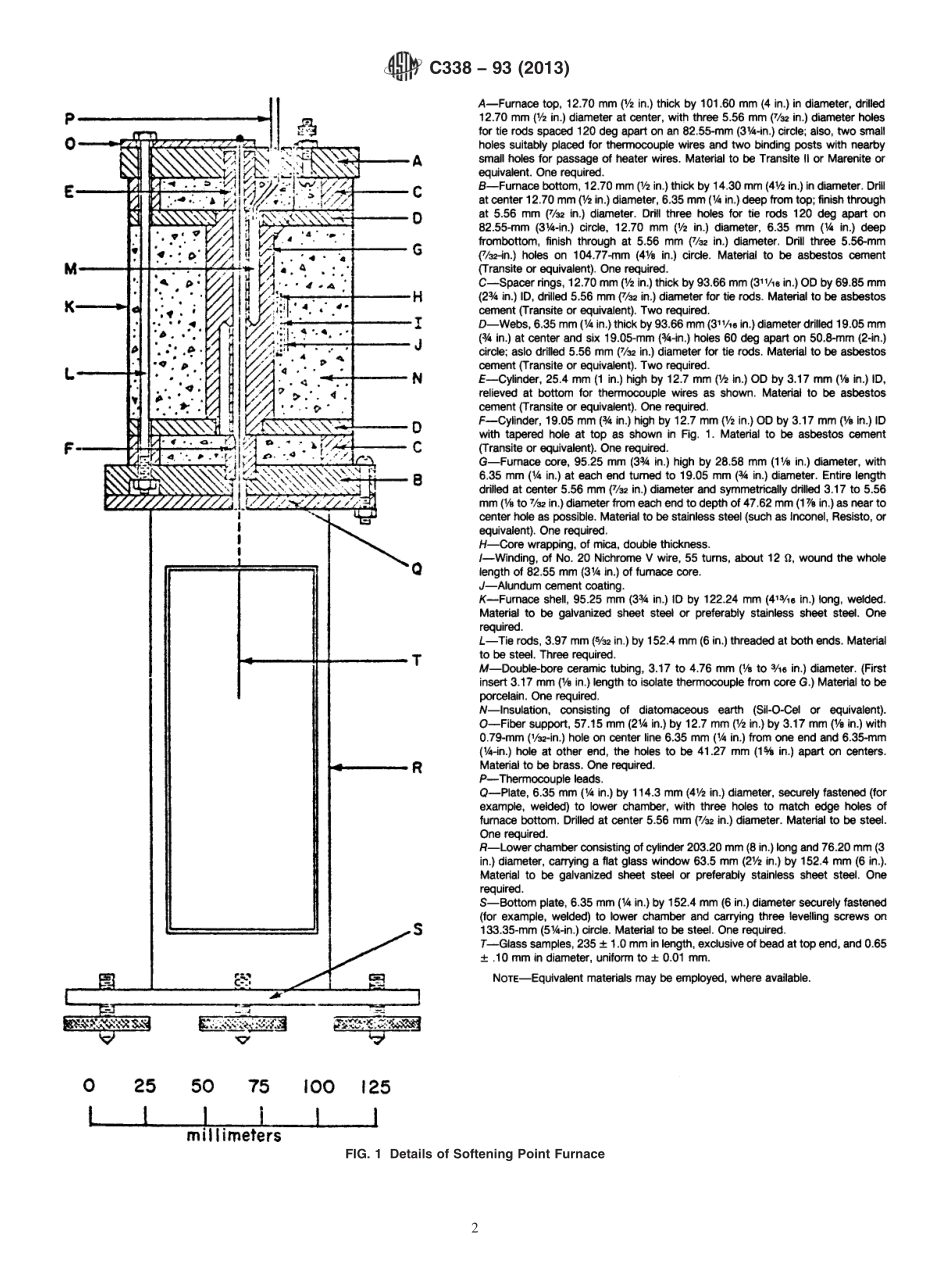

Designation:C338−93(Reapproved2013)StandardTestMethodforSofteningPointofGlass1ThisstandardisissuedunderthefixeddesignationC338;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope1.1Thistestmethodcoversthedeterminationofthesoft-eningpointofaglassbydeterminingthetemperatureatwhicharoundfiberoftheglass,nominally0.65mmindiameterand235mmlongwithspecifiedtolerances,elongatesunderitsownweightatarateof1mm/minwhentheupper100mmofitslengthisheatedinaspecifiedfurnaceattherateof561°C/min.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.SignificanceandUse2.1Thistestmethodisusefultodetermineapproximatelythetemperaturebelowwhichtheglassbehavesasarigidsolidinglass-formingoperationsandforacontroltesttoindicatechangesincomposition.Ithasbeenfoundusefulforspecifi-cationacceptanceandforprovidinginformationinresearchanddevelopmentworkwithglass.3.Apparatus3.1Theapparatusfordeterminingthesofteningpointofglassshallconsistessentiallyofanelectricallyheatedresis-tancefurnace,afurnacestand,adeviceforcontrollingtheheatingrateofthefurnace,equipmentformeasuringthetemperatureofthefurnace,andequipmentformeasuringtheelongationrateofafiberofglasssuspendedinthefurnace.3.1.1Furnace—ThefurnaceshallconforminallessentialrespectstotherequirementsshowninFig.1.3.1.2FurnaceStand—Ameansshallbeprovidedforsup-portingthefurnacesothatthefiberhangsbelowit.Thisstandmustbeprovidedwithalevelingdevicesuchasthreescrews.ThestandshowninFig.1isconve...