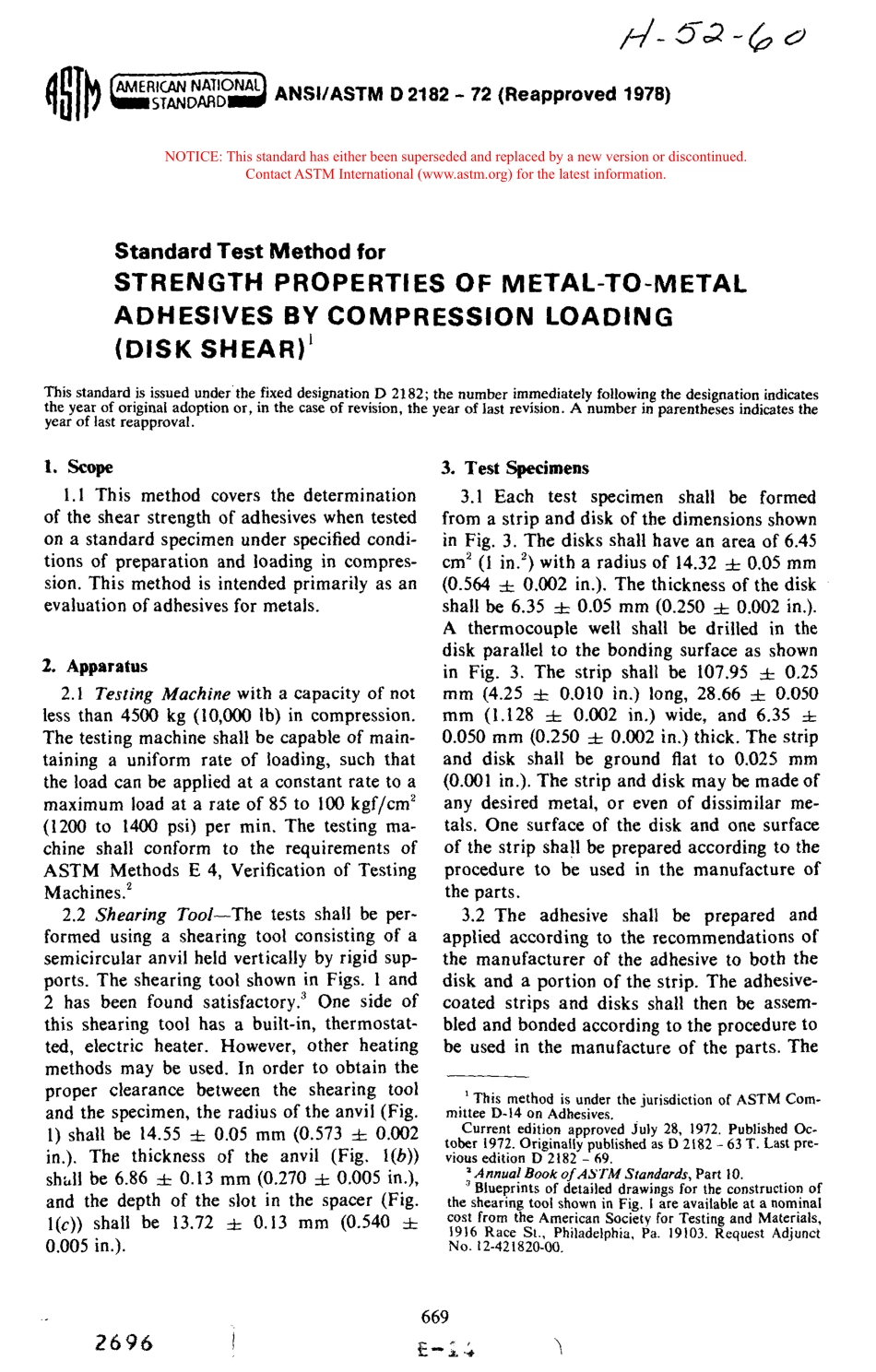

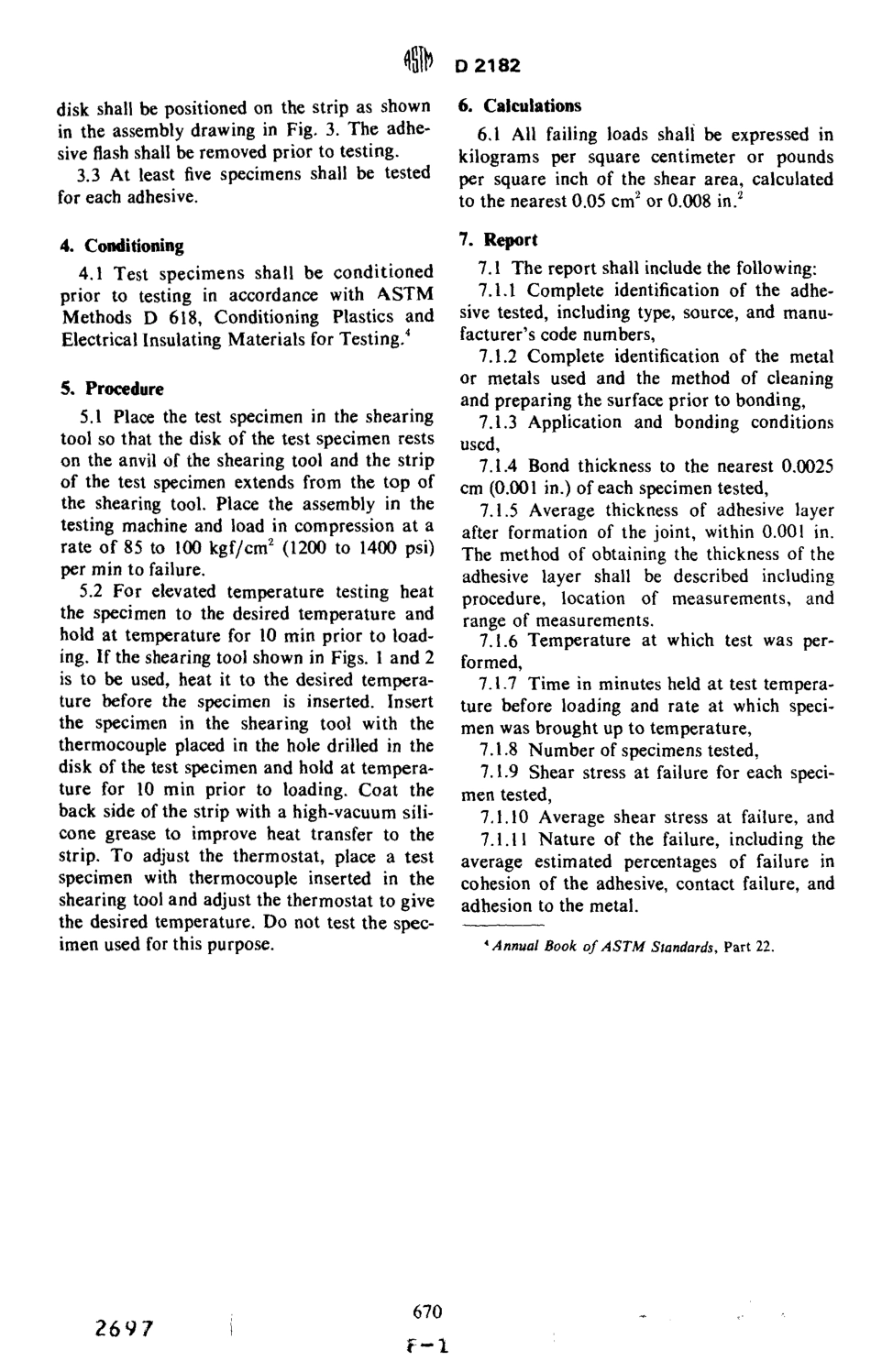

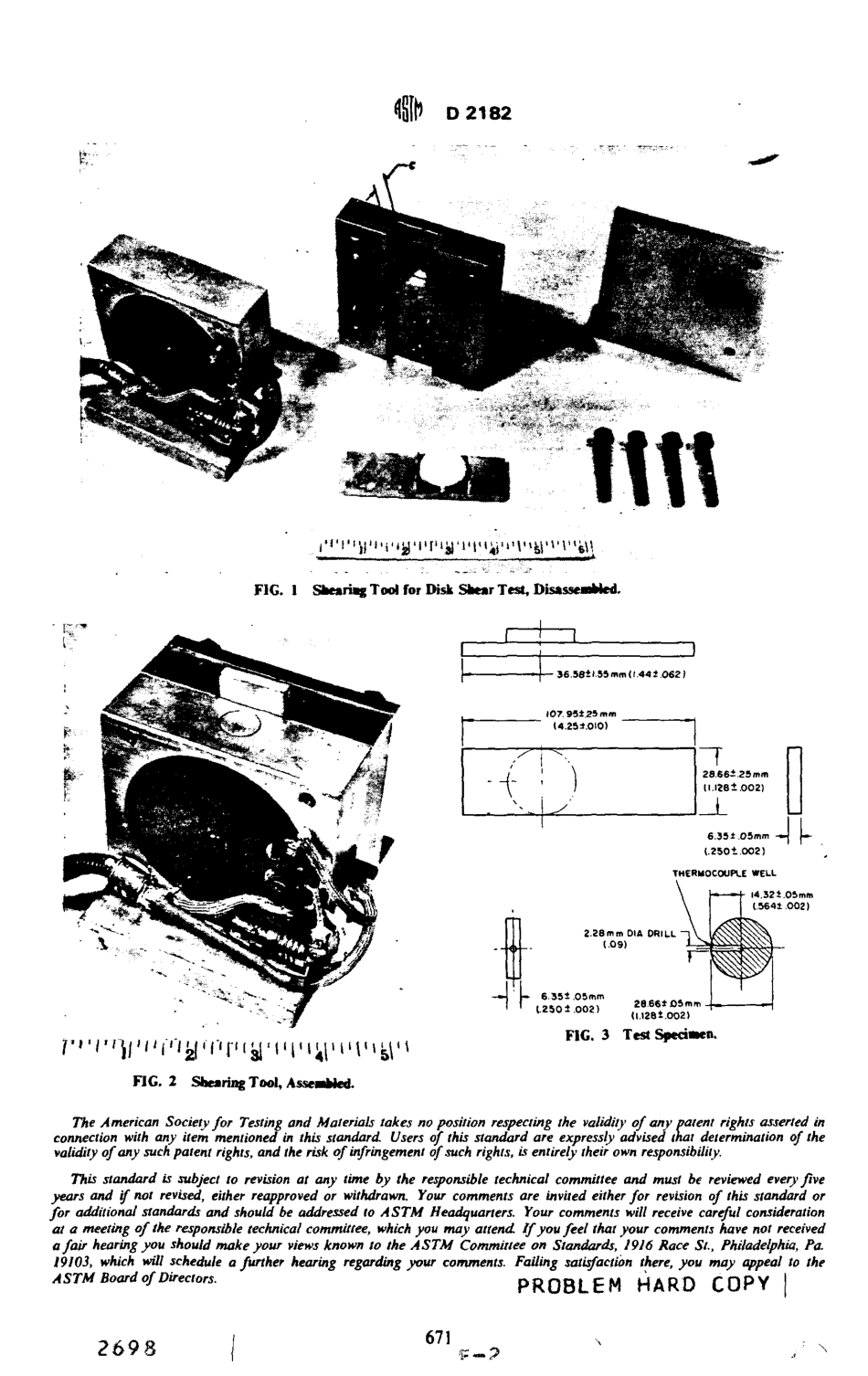

;-/-5:i-0C,)~~r~=R~~~~~o.:JANSI/ASTMD2182-72(Reapproved1978)StandardTestMethodforSTRENGTHPROPERTIESOFMETAL-TO-METALADHESIVESBYCOMPRESSIONLOADING(DISKSHEAR)1ThisstandardisissuedunderthefixeddesignationD2182;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.I.Scope1.1Thismethodcoversthedeterminationoftheshearstrengthofadhesiveswhentestedonastandardspecimenunderspecifiedcondi-tionsofpreparationandloadingincompres-sion.Thismethodisintendedprimarilyasanevaluationofadhesivesformetals.2.Apparatus2.1TestingMachinewithacapacityofnotlessthan4500kg(10,000lb)incompression.Thetestingmachineshallbecapableofmain-tainingauniformrateofloading,suchthattheloadcanbeappliedataconstantratetoamaximumloadatarateof85to100kgf/cm2(1200to1400psi)permin.Thetestingma-chineshallconformtotherequirementsofASTMMethodsE4,VerificationofTestingMachines.22.2ShearingTool-Thetestsshallbeper-formedusingashearingtoolconsistingofasemicircularanvilheldverticallybyrigidsup-ports.TheshearingtoolshowninFigs.land2hasbeenfoundsatisfactory.3Onesideofthisshearingtoolhasabuilt-in,thermostat-ted,electricheater.However,otherheatingmethodsmaybeused.Inordertoobtaintheproperclearancebetweentheshearingtoolandthespecimen,theradiusoftheanvil(Fig.l)shallbe14.55±0.05mm(0.573±0.002in.).Thethicknessoftheanvil(Fig.l(b))shullbe6.86±0.13mm(0.270±0.005in.),andthedepthoftheslotinthespacer(Fig.l(c))shallbe13.72±0.13mm(0.540±0.005in.).26963.TestSpecimens3.lEachtestspecimenshallbeformedfromastripanddiskofthedimensionsshowninFig.3.Thedisksshallhaveanareaof6.45cm2(lin.2)witharadiusof14.32±0.05mm(0.564±0.002in.).Thethicknessofthediskshallbe6.35±0.05mm(0.250±0.002in.).AthermocouplewellshallbedrilledinthediskparalleltothebondingsurfaceasshowninFig.3.Thestripshallbe107.95±0.25mm(4.25±0.010in.)long,28.66±0.050mm(l.128±0.002in.)wide,and6.35±0.050mm(0.250±0.002in.)thick.Thestripanddiskshallbegroundflatto...