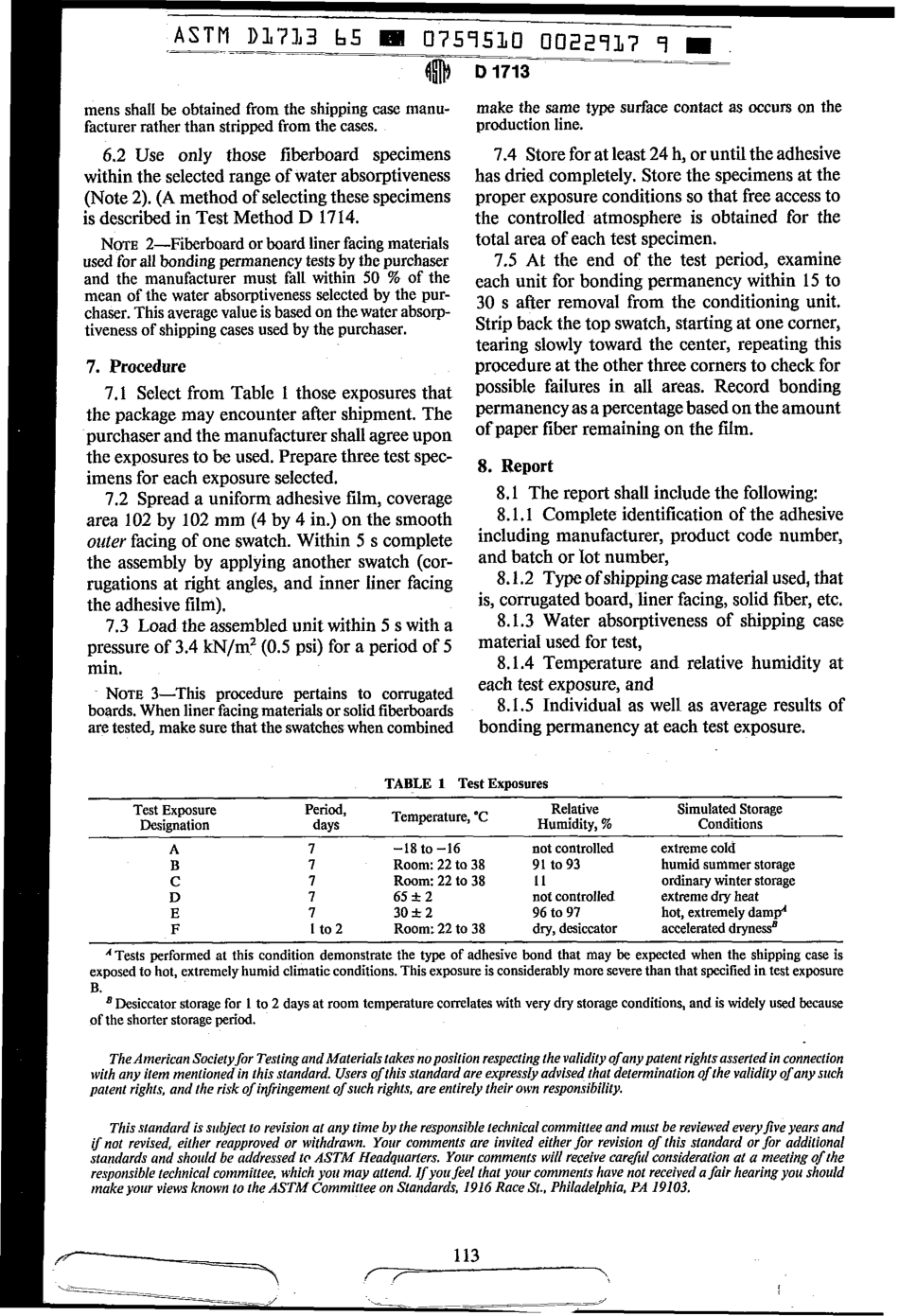

ASTMD371365U075753000229367UHd52-La~-~Designation:D1713-65(Reapproved1986)StandardTestMethodforBONDINGPERMANENCYOFWATER-ORSOLVENT-SOLUBLELIQUIDADHESIVESFORAUTOMATICMACHINESEALINGTOPFLAPSOFFIBERBOARDSPECIMENS'ThisstandardisissuedunderthefuceddesignationD171%thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearofisstrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asnpescriptepsilon(E)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversdeterminationofthebondingpermanencyofdextrin,casein,starch,resinbase,andotherwater-orsolvent-solubleliquidadhesives(excludingpressure-sen-sitivetypes)usedforsealingthetopflapsoffiberboardshippingcases,1.2Thisstandardmayinvolvehazardousma-terials,operations,andequipment.Thisstandarddoesnotpttrporttoaddressalloffhesajètyprob-lemsassociatedwithitsme.Itistheresponsibil-ityofwhoeverusesthisstandardtoconsitltandestablishappropriatesajètyandhealthpracticesanddeterminetheapplicabilityofregulatorylimi-tationspriortouse.2.ApplicableDocument2.IASTMStandard:D1714TestMethodforWaterAbsorptivenessofFiberboardSpecimensforAdhesives'3.Apparatus3.1FilmApplicator,tubeorrodtypetogiveawetfilmthicknessof0.025to0.0381mm(0.001to0.0015in.)onasmoothglassplate,andafimcoverage102by102mm(4by4in.)(Filmthicknesscannotbedeterminedaccuratelyonfiberboardmaterial.)3.2SolidBlackorHydraulicPresstoapplyapressureof3.4kN/m2(03psi.)3.3CabinetsorDesiccators,withmeansofcontrollingthetemperatureandrelativehumid-ityattheconditionslistedinTable1.4.Materiais4.1Desiccant'forcondytionof23&1%rel-ativehumidity.4.2SaturatedSaltSolutions:4.2.1Ammoniummonophosphatefordesig-natedconditionsof22to38"C,91to93%relativehumidity.4.2.2Potassiumsulfateforconditionsof30"C,96to97%relafivehumidity.4.2.3Lithiumchlorideforconditionsof22to38T,Il%relativehumidity.5.SamplingAdhesive5.1Theadhesivesampleshallbea0.9-litre(1-qt)aliquotconsistingofacompositetakenwhenpossiblefromthreeormoreseparatecon-tain...