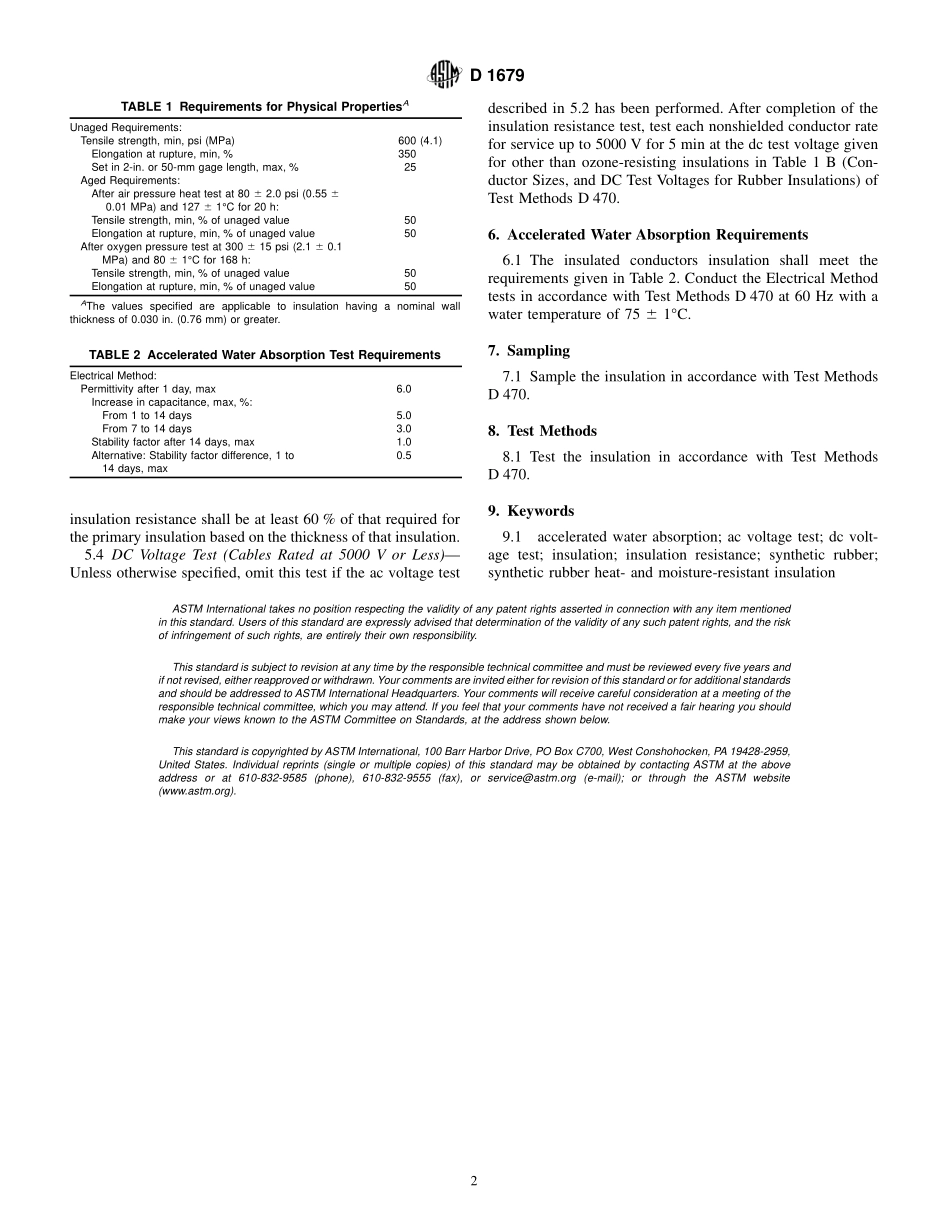

Designation:D1679–02AnAmericanNationalStandardStandardSpecificationforSyntheticRubberHeat-andMoisture-ResistingInsulationforWireandCable,75°COperation1ThisstandardisissuedunderthefixeddesignationD1679;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoversacrosslinkedrubberinsulatingcompoundforelectricalwiresandcables.Thepolymercon-sistssubstantiallyofsyntheticrubber.1.2Thistypeofinsulationissuitableforcontinuousopera-tionatconductortemperaturesnotexceeding75°Cindryorwetlocationsandoperatingvoltagesnotexceeding2000V.Thisinsulationmayhavelow-temperaturelimitations.Consultthemanufacturerforspecificrecommendationsforinstallationorapplication.1.3Whenevertwosetsofvaluesarepresented,indifferentunits,thevaluesinthefirstsetarethestandard,whilethoseinparenthesesareforinformationonly.1.4Inmanyinstancestheinsulationmaterialcannotbetestedunlessithasbeenformedaroundaconductororcable.Therefore,testsaredoneoninsulatedwireorcableinthisdocumentsolelytodeterminetherelevantpropertyoftheinsulationmaterialandnottotesttheinsulatedconductororcompletedcable.2.ReferencedDocuments2.1ASTMStandards:D470TestMethodsforCrosslinkedInsulationsandJacketsforWireandCable2D1711TerminologyRelatingtoElectricalInsulation23.Terminology3.1Definitions:Fordefinitionsoftermsusedinthisspeci-fication,refertoTerminologyD1711.3.2DefinitionsofTermsSpecifictoThisStandard:3.2.1aging(actof),n—exposureofmaterialstothefollow-ing:airat80psi(0.55MPa)and127°Cfor20h;exposuretooxygenat300psi(2.1MPa)and80°Cfor168h.4.PhysicalProperties4.1RequirementsforphysicalpropertiesarelistedinTable1.4.2ThicknessofInsulation—Table1A(ConductorSizes,InsulationThicknessesandACTestVoltagesforRubberInsulations)ofTestMethodsD470liststheaveragethicknessfortheinsulation.Therequiredminimumthicknessisatleast90...