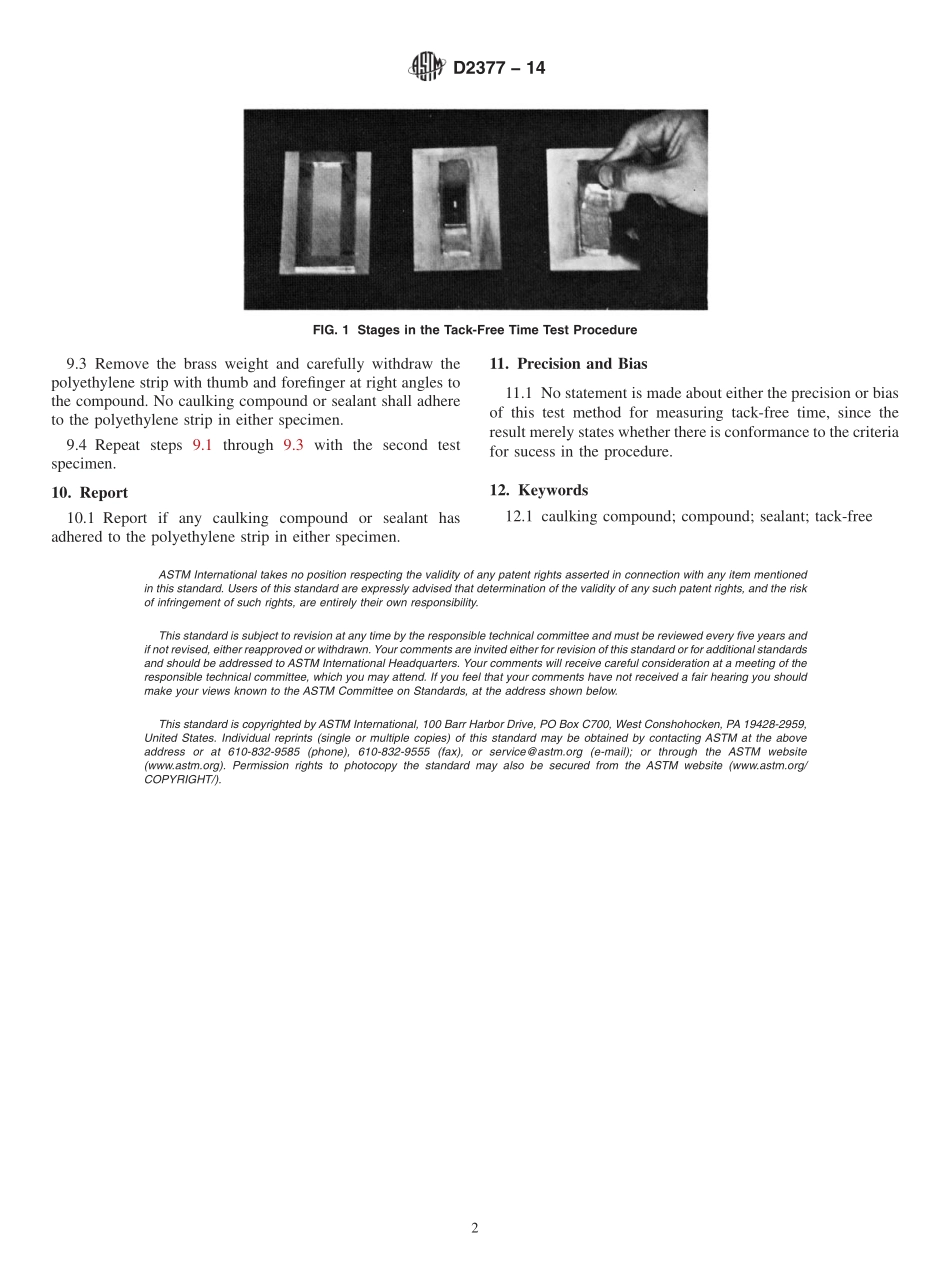

Designation:D2377−14StandardTestMethodforTack-FreeTimeofCaulkingCompoundsandSealants1ThisstandardisissuedunderthefixeddesignationD2377;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethoddescribesthedeterminationofthetack-freetimepropertyofcaulkingcompoundsandsealants.Thistestmethodisapplicabletobothgunandknifegrades.1.2Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.1.4Thecommitteewithjurisdictionoverthisstandardisnotawareofanycomparablestandardpublishedbyotherorgani-zations.2.ReferencedDocuments2.1ASTMStandards:2C717TerminologyofBuildingSealsandSealants3.Terminology3.1Definitions—RefertoTerminologyC717fordefinitionsofthefollowingterms:caulkingcompound,compound,seal-ant.4.Apparatus4.1CabinetorRoom,capableofmaintainingStandardConditionsasdefinedinTerminologyC717.4.2BrassSheet,3⁄4by11⁄2in.(19by38mm),approximately1⁄4in.(6.4mm)thick.4.3Template—Arectangulartemplateofsteelorbrass,1⁄8in.(3.2mm)thick,1by33⁄4in.(25.4by95.1mm)inside,andapproximately2by43⁄4in.(51by121mm)outside.4.4SteelSheets—Tworectangulartin-platedsteelsheets,approximately3by5in.(76by127mm),andofaconvenientthickness.4.5PlasticStrips—Two,clear,low-densitypolyethylenestrips,1by5in.(25.4by127mm)by0.00460.001in.(0.101660.0254mm)thick.4.6Spatula,steel,havinga4to5-in.(102to127-mm)longnarrowblade.4.7ThinKnifeBlade.5.Solvent5.1MethylEthylKetone,EthyleneDichloride,orsimilarsolvent.6.Conditioning6.1Conditionthesampleintheoriginalclosedcontainerforatleast5hatStandardConditionsasde...