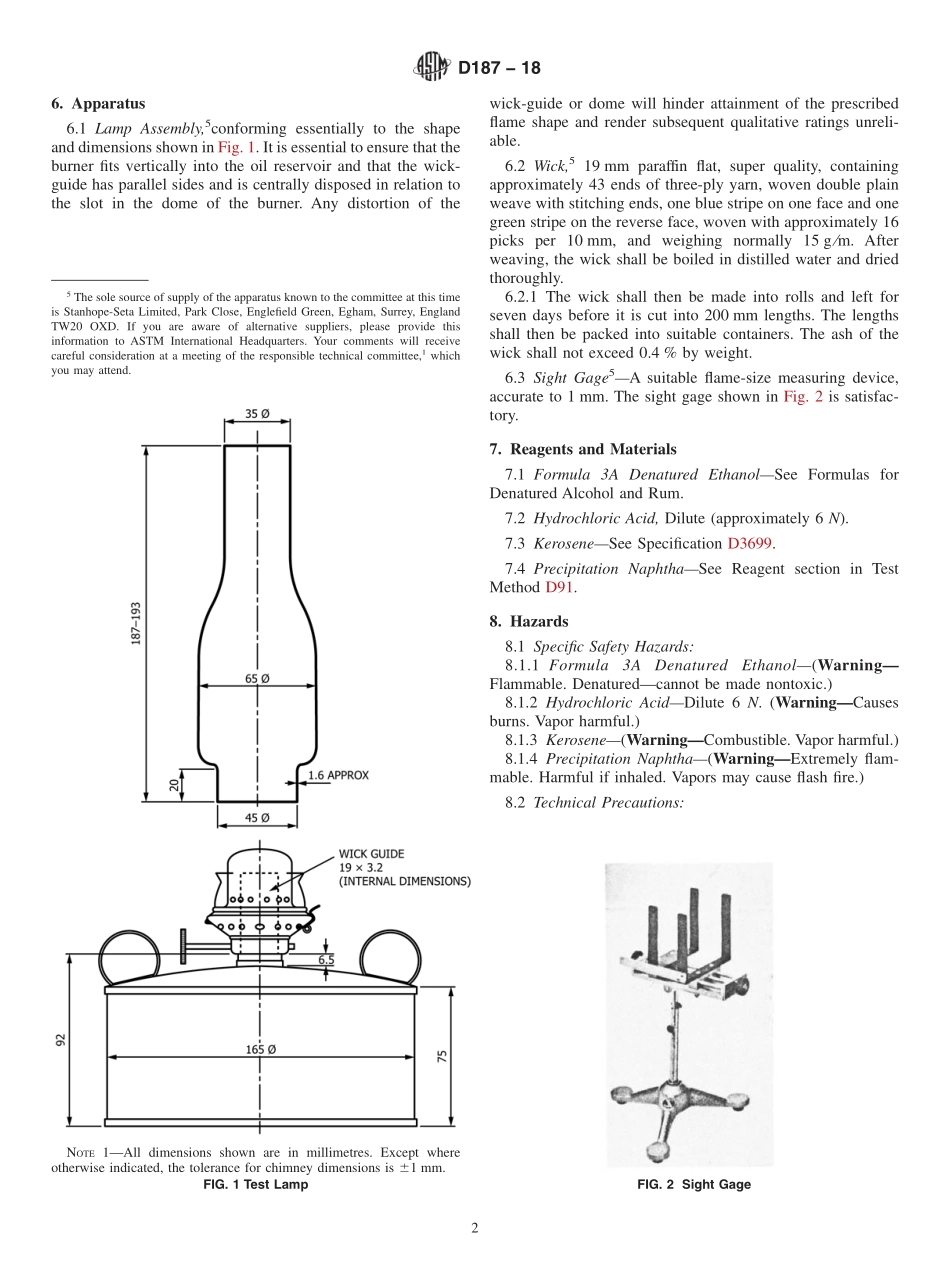

Designation:D187−18StandardTestMethodforBurningQualityofKerosene1ThisstandardisissuedunderthefixeddesignationD187;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope*1.1Thistestmethodcoversthequalitativedeterminationoftheburningpropertiesofkerosenetobeusedforilluminatingpurposes.(Warning—Combustible.Vaporharmful.)NOTE1—ThecorrespondingEnergyInstitute(IP)testmethodisIP10whichfeaturesaquantitativeevaluationofthewick-char-formingtenden-ciesofthekerosene,whereasTestMethodD187featuresaqualitativeperformanceevaluationofthekerosene.Bothtestmethodssubjectthekerosenetosomewhatmoresevereoperatingconditionsthanwouldbeexperiencedintypicaldesignatedapplications.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.Specificwarningstatementsappearthroughoutthetestmethod.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D91TestMethodforPrecipitationNumberofLubricatingOilsD3699SpecificationforKerosineD4057PracticeforManualSamplingofPetroleumandPetroleumProductsD4175TerminologyRelatingtoPetroleumProducts,LiquidFuels,andLubricantsD4177PracticeforAutomaticSamplingofPetroleumandPetroleumProducts2.2EnergyInstituteStandard:3IP10Deter...