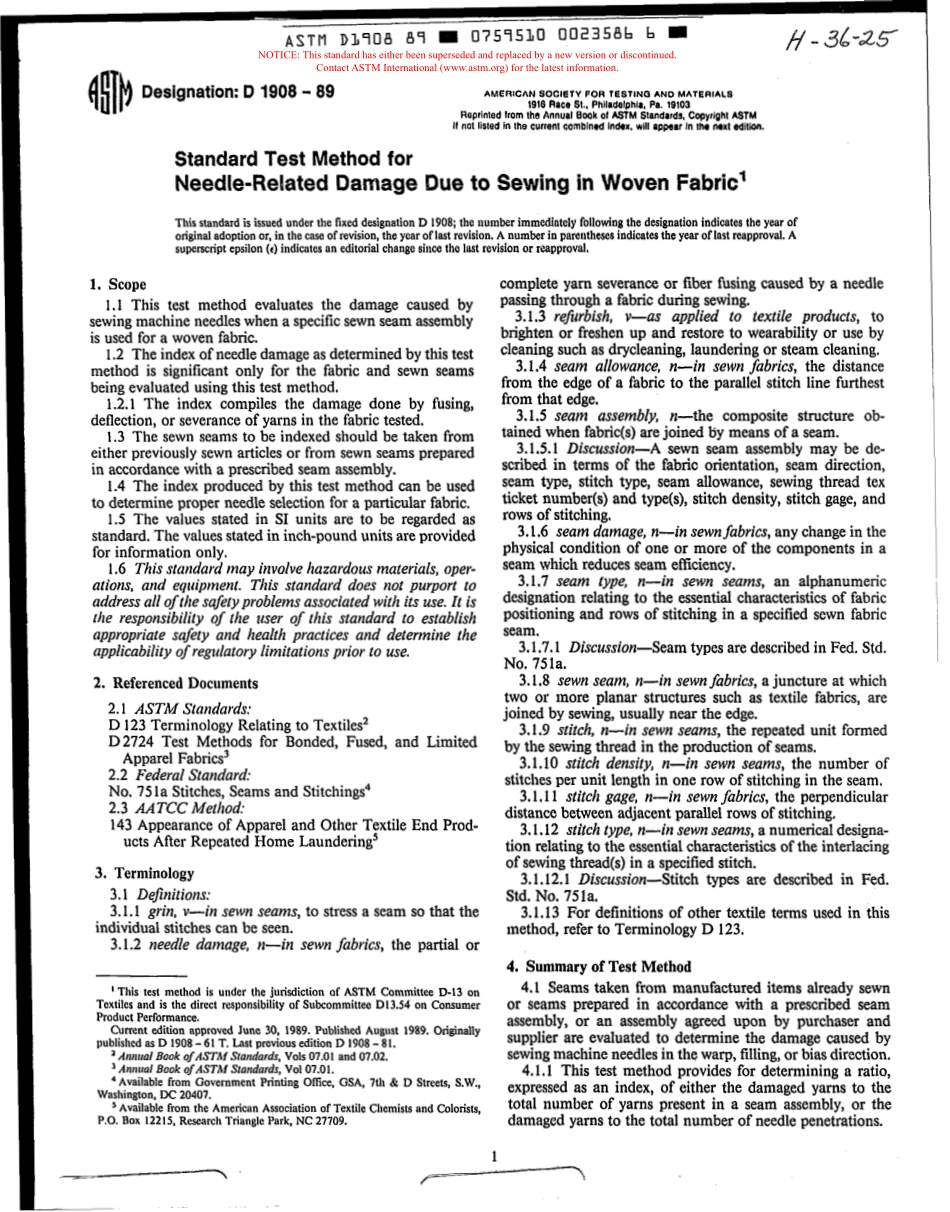

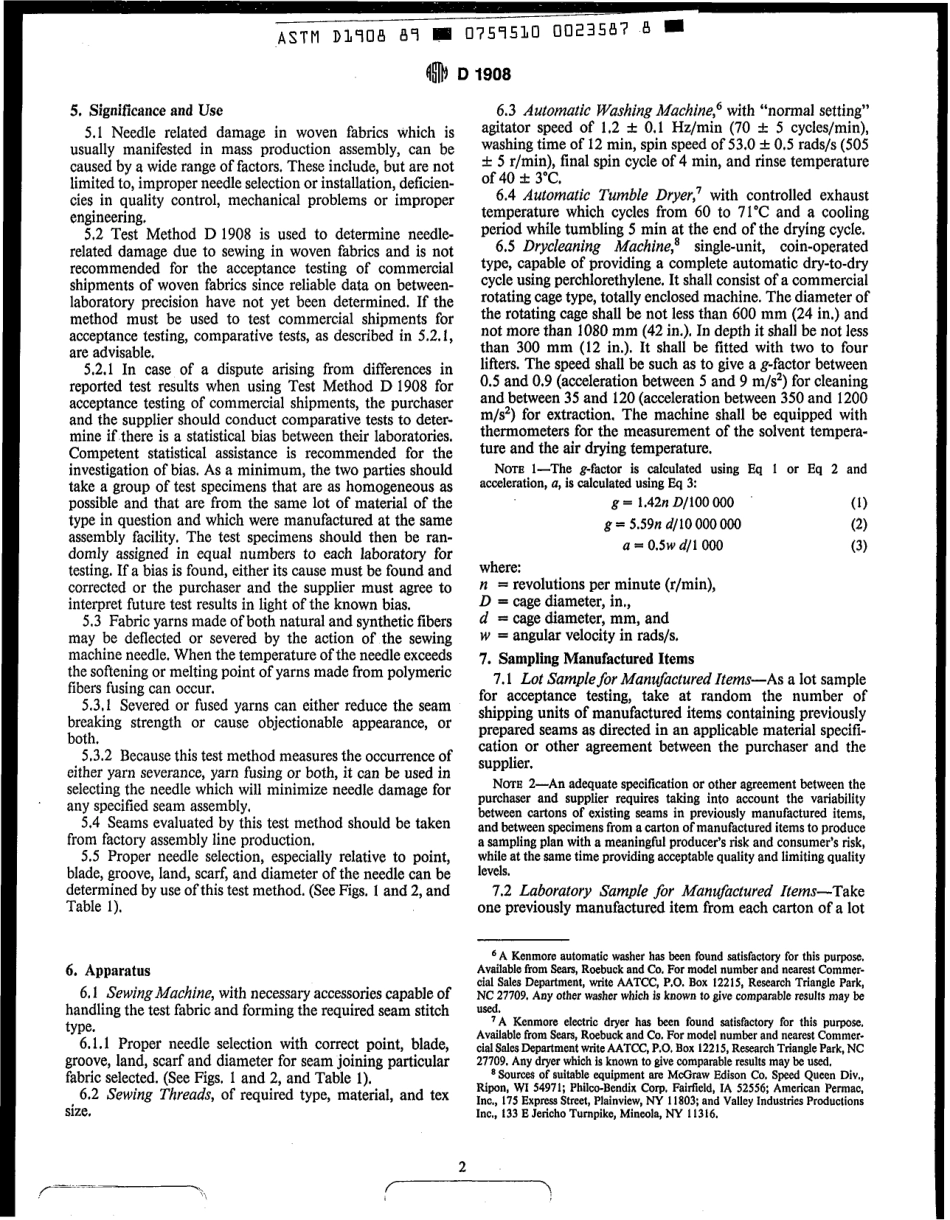

ASTMDI70887I0757530002358bbWN-3L-254&Designation:D1908-û9AMERICANSOCIETYFORTESTINOANDMATERIALS1918RaceSI.,Philallphia,Pa.19103RsprinledIromtheAnnualBook01MMStandards,CopyrightASTMIIna1listedinlhecurrent60mbinrclInk.willappearintheMXIediilon.StandardTestMethodforNeedle-ReaatedDamageQuetoSewinginWovenFabric'ThisstandardisissuedunderthefixeddesignationD1908;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparzathwesindicatestheyearoflastreapproval.Asuperscriptepsilon(0indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodevaluatesthedamagecausedbysewingmachineneedleswhenaspecificsewnseamassemblyisusedforawovenfabric.1.2Theindexofneedledamageasdeterminedbythistestmethodissignificantonlyforthefabricandsewnseamsbeingevaluatedusingthistestmethod.1.2.1Theindexcompilesthedamagedonebyfusing,deflection,orseveranceofyarnsinthefabrictested.1.3Thesewnseamstobeindexedshouldbetakenfromeitherpreviouslysewnarticlesorfromsewnseamspreparedinaccordancewithaprescribedseamassembly.1.4Theindexproducedbythistestmethodcanbeusedtodetermineproperneedleselectionforaparticularfabric.1.5ThevaluesstatedinSIunitsaretoberegardedasstandard.Thevaluesstatedininch-poundunitsareprovidedforinformationonly.1.6Thisstandardmayinvolvehazardoasmaterials,oper-ations,andequipment.Thisstandarddoesnotpurporttoaddressallofthesafetyproblemsassociatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:D123TerminologyRelatingtoTextiles2D2724TestMethodsforBonded,Fused,andLimitedApparelFabrics32.2FederalStandard:No.75laStitches,SeamsandStitchings42.3AATCCMethod:143AppearanceofApparelandOtherTextileEndProd-uctsAfterRepeatedHomeLaundering'3.Terminology3.1Definitions:3.1.1grin,v-insewnseams,tostressaseamsothatthe3.1.2needledamage,n-insewnfabrics,thepartialorindivi...